Eight new Bedfords unveiled for weights up to 32.5 tonnes

Page 89

Page 91

Page 92

Page 97

Page 98

If you've noticed an error in this article please click here to report it so we can fix it.

UNVEILED to the public for the first time at Earls Court today are vehicles from a Bedford range which will extend eventually to the anticipated European maximum weight of 42 tonnes (4E3 tons). This new range designated TM — will take Bedford and General Motors into the maximum-weight category of Europe for the first time.

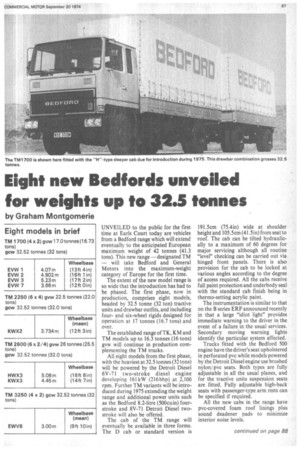

The extent of the new model range is so wide that the introduction has had to be phased. The first phase, now in production, comprises eight models, headed by 32.5 tonne (32 ton) tractive units and drawbar outfits, and including fourand six-wheel rigids designed for operation at 17 tonnes (16.7 tons) and over.

The established range of TK, KM and TM models up to 16.3 tonnes (16 tons) gvw will continue in production complementing the TM trucks.

All eight models from the first phase, with the heaviest at 32.5 tonnes (32 tons) will be powered by the Detroit Diesel 6V-71 two-stroke diesel engine developing 161 kW (216bhp) at 2,100 rpm. Further TM variants will be introduced during 1975 extending the weight range and additional power units such as the Bedford 8.2-litre (500cuin) fourstroke and 8V-71 Detroit Diesel twostroke will also be offered.

The cab of the TM range will eventually be available in three forms. The D cab or standard version is 191.5cm (75.4in) wide at shoulder height and 105.5cm (41 Sin) from seat to roof. The cab can be tilted hydraulically to a maximum of 60 degrees for major servicing although all routine "level" checking can be carried out via hinged front panels. There is also provision for the cab to be locked at various angles according to the degree of access required. All the cabs receive full paint protection and underbody seal with the standard cab finish being in thermo-setting acrylic paint.

The instrumentation is similar to that on the B series ERF announced recently in that a large "idiot light" provides immediate warning to the driver in the event of a failure in the usual services. Secondary moving warning lights identify the particular system affected.

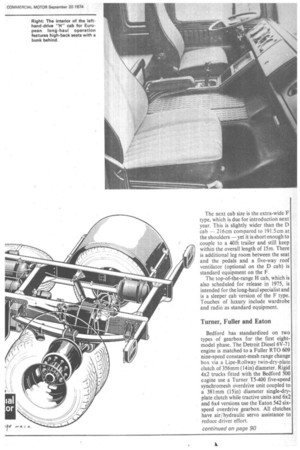

Trucks fitted with the Bedford 500 engine have the driver's seat upholstered in perforated pvc while models powered by the Detroit Diesel engine use brushed nylon/ pvc seats. Both types are fully adjustable in all the usual planes, and for the tractive units suspension seats are fitted. Fully adjustable high-back seats with passenger-type arm rests can be specified if required.

All the new cabs in the range have pvc-covered foam roof linings plus sound deadener pads to minimize interior noise levels. The next cab size is the extra-wide F type, which is due for introduction next year. This is slightly wider than the D cab — 216cm compared to 191.5cm at the shoulders — yet it is short enough to couple to a 40ft trailer and still keep within the overall length of 15m. There is additional leg room between the seat and the pedals and a five-way roof ventilator (optional on the D cab) is standard equipment on the F.

The top-of-the-range H cab, which is also scheduled for release in 1975, is intended for the long-haul specialist and is a sleeper cab version of the F type. Touches of luxury include wardrobe and radio as standard equipment.

Turner, Fuller and Eaton

Bedford has standardized on two types of gearbox for the first eightmodel phase. The Detroit Diesel 6V-71 engine is matched to a Fuller RTO 609 nine-speed constant-mesh range change box via a Lipe-Rollway twin-dry-plate clutch of 356mm (14in) diameter. Rigid 4x2 trucks fitted with the Bedford 500 engine use a Turner T5-400 five-speed synchromesh overdrive unit coupled to a 381mm (15in) diameter single-dryplate clutch while tractive units and 6x2 and 6x4 versions use the Eaton 542 sixspeed overdrive gearbox. All clutches have air! hydraulic servo assistance to reduce driver effort. The rear axle used in the 15 and 17 tonne rigids with the 500 engine is an 11 tonne (10.8 tons) capacity spiral-bevel unit of Bedford's own design.

Tractive units fitted with the 500 engine use Eaton spiral-bevel rear axles and all the TM models using Detroit Diesel engines with one exception take an Eaton 19128, 11 tonne capacity axle.

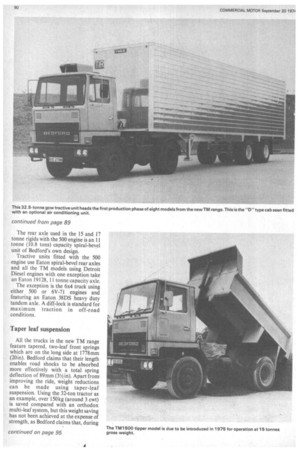

The exception is the 6x4 truck using either 500 or 6V-71 engines and featuring an Eaton 38DS heavy duty tandem axle. A diff-lock is standard for maximum traction in off-road conditions.

Taper leaf suspension

All the trucks in the new TM range feature tapered, two-leaf front springs which are on the long side at 1778mm (201n). Bedford claims that their length enables road shocks to be absorbed more effectively with a total spring deflection of 89mm (31/2in). Apart from improving the ride, weight reductions can be made using taper-leaf suspension. Using the 32-ton tractor as an example, over 150kg (around 3 cwt) is saved compared with an orthodox multi-leaf system, but this weight saving has not been achieved at the expense of strength, as Bedford claims that, during he entire one million miles of TM :ndurance running, not one taper-leaf ipring failed.

On the TM 3250 tractive unit, these prings are also fitted at the rear, but in his case they are 1524mm (60in) long ind have slipper type rear ends to give he variable rate needed for optimum ide conditions where there is a big adenj unladen variation in axle load.

Rigid four and six-wheelers have nulti leaf springs at the rear as part of a :.ompensated four-spring bogie arrangenent. Soft springs (nine instead of 10 leaves) are used on the trailing axle of the 6x2 TM 2600 to help to alter the weight bias on to the driving axle for improved traction. Bonded rubber spring-eye and shackle bushes eliminate all suspension lubrication throughout the TM range.

Brakes

The braking system of the new Bedfords is designed to meet the legal requirements of the EEC and other major truck markets. On all models the full air-operated system has both service and secondary braking operated by the foot pedal with separate control for the parking brake. The system has independent circuits actuated by a footbrake dual-concentric valve and each circuit utilizes protection valves strategically placed to prevent a loss of braking should a pipe fracture occur by allowing the remaining tank to be replenished.

Two-axle rigid TMs are equipped with single-diaphragm brake chambers on the front axles while three-axle units use the triple disphragm type. All rear axles are flitted with single diaphragm spring brake units. The parking brake is also air operated and has a gradual response depending on the position of the control valve. The lining frictional area of the two axle rigids and tractive unit is 5,864cm (909 sqin) with 8,992sqem (1,399 sq in) for the sixwheelers. A load sensing valve is connected to the rear springs of all the new TM models.

Optional equipment includes an exhaust brake for the Bedford 500 engine and the Jacobs brake for the Detroit Diesels.

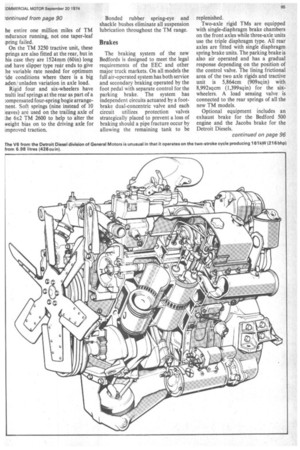

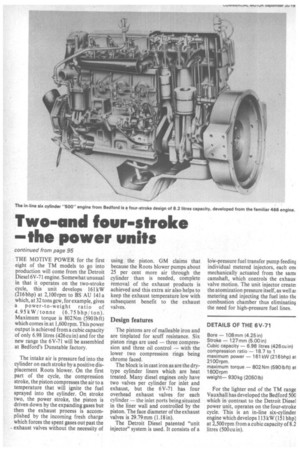

THE MOTIVE POWER for the first eight of the TM models to go into production will come from the Detroit Diesel 6V-71 engine. Somewhat unusual in that it operates on the two-stroke cycle, this unit develops 161 kW (216 bhp) at 2,100 rpm to BS AU 141a which, at 32 tons gcw, for example, gives a power-to-weight ratio of 4.95 kW/tonne (6.75 bhp/ ton). Maximum torque is 802 Nm (5901b ft) which comes in at 1,600 rpm. This power output is achieved from a cubic capacity of only 6.98 litres (426 cu in) and for the new range the 6V-71 will be assembled at Bedford's Dunstable factory.

The intake air is pressure fed into the cylinder on each stroke by a positive displacement Roots blower. On the first part of the cycle, the compression stroke, the piston compresses the air to a temperature that will ignite the fuel sprayed into the cylinder. On stroke two, the power stroke, the piston is driven down by the expanding gases but. then the exhaust process is accomplished by the incoming fresh charge which forces the spent gases out past the exhaust valves without the necessity of using the piston. GM claims that because the Roots blower pumps about 25 per cent more air through the cylinder than is needed, complete removal of the exhaust products is achieved and this extra air also helps to keep the exhaust temperature low with subsequent benefit to the exhaust valves.

Design features

The pistons are of malleable iron and are tinplated for scuff resistance. Six piston rings are used — three compression and three oil control — with the lower two compression rings being chrome faced.

The block is in cast iron as are the drytype cylinder liners which are heat treated. Many diesel engines only have two valves per cylinder for inlet and exhaust, but the 6V-71 has four overhead exhaust valves for each cylinder -the inlet ports being situated in the liner wall and controlled by the piston. The face diameter of the exhaust valves is 29.79 mm (1.18 in).

The Detroit Diesel patented "unit injector" system is used. It consists of a low-pressure fuel transfer pump feedini individual metered injectors, each on mechanically actuated from the saint camshaft, which controls the exhaus valve motion. The unit injector create! the atomization pressure itself, as well a! metering and injecting the fuel into th( combustion chamber thus eliminatin4 the need for high-pressure fuel lines.