HINTS ON MAINTENANCE.

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

CONTRIBUTIONS are invited for this page from fleet managers, drivers, .garage: foremen and mechanics, works staff and draughtsmen, and will be paid for on a generous scale. Every system, make, and type of commercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle—practices

which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, headed "Roadside and Garage." Communications should be addressed to "The Editor, The Commercial Motor, 7-15, Rosebery Avenee, London, E.C. 1."

87.—Keeping Tylor Engine Clean.

The front end of a Tylor.engine, such as is employed on many W.D. type chassis, becomes vary dirty after a time, owing to the fact that a considerable amount of oil appea•rs to be thrown out from the crankshaft where it emerges from the front cover of the timing case.

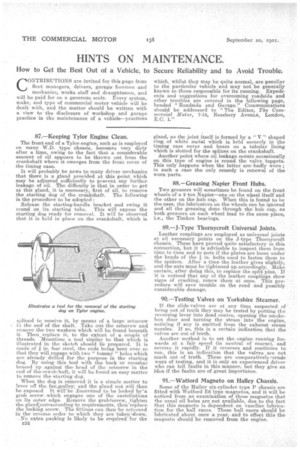

It will probably be news to many driver mechanics that there is a gland provided at this point which may be adjusted sufficiently to prevent any further. leakage of oil. The difficulty is that in order to get at this gland, it is necessary, 'first of all, to remove the starting dog of the crankshaft. The following is the procedure to be adopted : Release the starting-handle bracket and swing it round on its starting tube. This will expose the starting dog ready for removal. It will be observed that it is held in place on the crankshaft, which is splined to receive it, by means of a large setscrew the end of the shaft. ,Take out the setscrew and remove the two washers which will be. found beneath it. Then, replace it, to the extent of a. couple of threads. Meantime a. tool similar to. that which is illustrated in the sketch should Ve prepared. It is made of in. bar steel, the ends being bent over so that they will engage with two " tomray " holes which are already' drilled for the purpose in the. starting dog. By using this tool with the back or crossbar braced up against thehead of the setscrew in the end of the•erankc.haft, it will be found an easy matter to remove the .starting dog.

When the dog is .re-moved it is a simple matter to lever off the fanipulley; and the gland nut will then be exposed It will-be dis.eovered• to. be locked by'a grub screw-, which engages one of the castellations on its outer edge. Remove the grubtscrew. tighten the gIandroutetceorcling to requirements, then replace the locking screw. The fittings can therebe returned in the 'reveree order to which they are takenl-down.

• No extra packing is likely to be required for the 134 gland, as the joint itself is formed by a "IT" shaped ring, of white metal which is held securely in the timing case cover and bears on a tubular lining which is slotted for the splines on the crankshaft. Another point where oil leakage occurs occasionally on this type of engine is round the valve tappets. This only happens when the latter are badly worn; in such a case the only remedy is renewal of the worn parts.

88.—Greasing Napier Front Hubs.

Two greasers will sometimes be found on the front wheels of a 2 ton Napier—one on• the wheel itself and the other on the hub. cap. When this is found to be the case, the lubricators on the wheels can be ignored and all the greasing done through the hub cap, as both greasers on each wheel lead to the same pjace, i.e., the Timken bearings.

89.—J-Type Thornycroft Universal Joints.

Leather couplings are employed as universal joints at all necessary points on the J.-type Thornycroft chassis. These have proved quite satisfactory in this connection, but it is advisable to inspect them from time to time and to note if the plates are loose under the heads of the in. bolts used to fasten them to the spiders. After a time the leather gives slightly, and the nuts must be tightened up accordingly. Make certain, after doing this to replace the split pins. If it is noticed that any a the leather couplings show signs of cracking, renew them at once. This procedure will save trouble on the road and possibly considerable damage.

90.—Testing Valves on Yorkshire Steamer.

If the slide-valves are at any time suspected of being out of truth they may be tested by putting the reversing lever into dead centre, opening the smokebox door and turning the steam into the engine, noticing if any is emitted from the exhaust steam nozzles. If so, this is a certain indication that the valves are out of truth.

Another method is to set the. engine running forwards at a fair speed (in neutral of course), and reverse it rapidly. If it reverses and continues to run, this is an indication that the valves are not much out of truth. These are comparatively crude ways of testing, and it is only an experienced driver who can tell faults in this manner, but they give an idea, if the faults are of great importance.

91.—Watford Magneto on Halley Chassis.

Some of the Halley six-cylinder type P chassis are fitted with Watford E6 type magnetos, and it will be noticed from an examination of these magnetos that the usual oil holes are not available, due to the fact that this magneto is dependent on vascline lubrication for the ball races. These ball races should be lubricated about once a year,' and to effect this the magneto should be removed from the engine. The driving couplings having been removed from the magneto armature shaft the big-end dust cover should next be taken off, so that the nuts holding the bottom cover can be loosened, and the cover withdrawn to give accessibility to this rear bearing. In the case of the front end it is necessary, to remove the contact breaker and then to withdraw the front cover, which gives accessibility to the front bearing. These bearings and races should then be carefully smeared with vaseline and the, whole re erected.