• The Amsterdam show earlier this year saw the debut

Page 52

Page 53

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

of the Philips' concept, which incorporates large-volume demountable bodies hauled by a drawbar.

The specification calls for an internal height of 3m, two useable bed lengths of 8.05m and a load width of 2.44m. Within the next few years Philips plans to have some 5,000 demount containers in use throughout Europe. These will be loaded at the end of the production line and so reduce warehousing overheads.

In order to accommodate two containers on a single vehicle the truck and trailer combination has to be modified to give a low frame height of just 850nun and the drawbar design has to allow for close coupling.

The first UK-based company to operate this type of vehicle, Brit European, put the first of four combinations on order from MAN into service this month. Prior to delivery we were able to take a 22.331 6x2x2 combination on test Dimd CM's 1,180km Scottish route, fully len to the present UK drawbar limit of .52 tonnes.

We would like to thank carpet tile mufacturer Heuga of Aylesbury for proling us with a palletised test load at art notice.

In Europe permissible operational ?.ights of up to 40 tonnes lessens the portance of available payload and even the UK it is possible to find loads that II fill the available space before exceed; the overall weight limit. All types of ads are increasingly being packed on mdardised pallets, which set the basic nensions determining vehicle design.

• BODYWORK

Our 22.331 MAN drawbar combination, constructed with an underfloor engine, low-section tyres and low-set frame, is designed to carry up to 40 Euro pallets.

MAN is the only commercial vehicle manufacturer to offer air suspension on all axles. Air pressure in each of the air bags, installed between the axle and spring carrier attached to the chassis, is compensated by height-regulating valves for changes in the load condition, to provide a constant and level-ride height.

As the air springs are only designed to absorb vertical forces other means have to be provided to locate axles. Positive location on the driven and trailing axles takes the form of trailing arms, a triangulated link and an anti-roll bar. On the front axle high-mounted spring links prevent longitudinal movement and control arms locate laterally. In order to eliminate vertical oscillation telescopic shock absorbers are fitted to all of the axles.

As an aid to mobility the suspension can be raised up to 140mm from within the cab. Lowering the chassis 80mm allows the body system to be demounted or, alternatively, it can be used to negotiate 4m low-clearance bridges. Raising the trailing axle imposes extra load on the drive axle to aid traction.

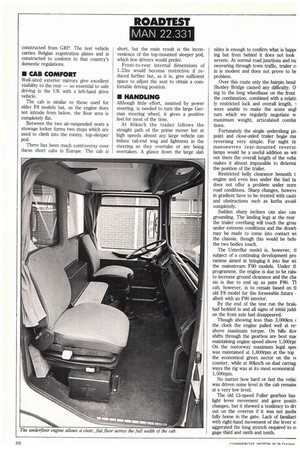

Installation of the horizontal engine low down and further back in the chassis renders the conventional cab-tilting facility obsolete. A side panel gives access to the engine below chassis level. The cab's fixed mounting retains the four-point suspension and enables the demount body to be placed close up to the rear panel. The cab's mainly steel construction incorporates a plastic front grille panel while the bumper, with integrated front apron, is constructed from GRP. The test vehicle carries Belgian registration plates and is constructed to conform to that country's domestic regulations.

• CAB COMFORT

Well-sited exterior mirrors give excellent visibility to the rear — so essential to safe driving in the UK with a left-hand drive vehicle.

The cab is similar to those used for older F8 models but, as the engine does not intrude from below, the floor area is completely flat.

Between the two air-suspended seats a stowage locker forms two steps which are used to climb into the roomy, top-sleeper Pod.

There has been much controversy over these short cabs in Europe. The cab is short, but the main result is the inconvenience of the top-mounted sleeper pod, which few drivers would prefer.

Front-to-rear internal dimensions of 1.23m would become restrictive if reduced further but, as it is, give sufficient space to adjust the seat to obtain a comfortable driving position.

• HANDLING

Although little effort, assisted by power steering, is needed to turn the large German steering wheel, it gives a positive feel for most of the time.

At 80km/h the trailer follows the straight path of the prime mover but at high speeds almost any large vehicle can induce tail-end wag and lightness in the steering as they overtake or are being overtaken. A glance down the large slab

sides is enough to confirm what is happ( ing but from behind it does not look severe. At normal road junctions and nu oeuvering through town traffic, trailer ci in is modest and does not prove to be problem.

Over this route only the hairpin bend Shotley Bridge caused any difficulty. 0 ing to the long wheelbase on the front the combination, combined with a relath ly restricted lock and overall length, I were unable to make the acute angl turn which we regularly negotiate w maximum weight, articulated combir tions.

Fortunately the single underslung pi point and close-axled trailer bogie ma reversing very simple. For night tir manoeuvres rear-mounted reversi: lamps would be a useful addition as wii out them the overall length of the vehic makes it almost impossible to detenni the position of the trailer.

Restricted belly clearance beneath t engine and even less under the fuel ta does not offer a problem under nom road conditions. Sharp changes, howevE in gradient have to be treated with cauti, and obstructions such as kerbs avoid, completely.

Sudden sharp inclines can also cau grounding. The landing legs at the rear the trailer overhang will touch the grow under extreme conditions and the drawb may be made to come into contact wi the chassis, though this would be befo the two bodies touch.

The Unterflur model is, however, tl subject of a continuing development pro ramme aimed at bringing it into line wi the mainstream F90 models. Under tt programme, the engine is due to be raist to increase ground clearance and the cha sis is due to end up as pure F90. TI cab, however, is to remain based on old F8 model for the forseeable.future albeit with an F90 interior.

By the end of the test run the braki had bedded in and all signs of initial judd, on the front axle had disappeared.

Though showing less than 3,000km ( the clock the engine pulled well at re, above maximum torque. On hills dov shifts through the gearbox are best ma( maintaining engine speed above 1,500rpr On the motorway maximum legal spec was maintained at 1,800rpm at the top the economical green sector on the n counter, while at 801(m/h on dual carriag, ways the rig was at its most economical 1,50Orpm.

No matter how hard or fast the vehic was driven noise level in the cab remain( at a very low level.

The old 13-speed Fuller gearbox has light lever movement and gave posith changes, but it showed a tendency to dr( out on the overrun if it was not push( fully home in the gate. Lack of familian with right-hand movement of the lever e: aggerated the long stretch required to el gage third and ninth and tenth. A Belgium calibration sticker confirmed the accuracy of the tachometer but when it was checked over a measured distance against a stop watch it was found to be reading 12.5% slow, so that for an indicated 96km/h the true speed would have been 108Iun/h.

Over the hilly section the single-drive axle was found wanting on more than one occasion so that we had to activate the load transfer device to prevent wheelspin on the steeper and wet inclines.

The rigid chassis' long wheelbase certainly contributes to a smooth ride but the cab suspension allows a certain amount of nodding.

• After a favourable start on the first part of the route high winds on the last day removed all possibility of achieving either good journey times or fuel consumption results. Gusts of up to 72km/h made driving at speeds above 80km/h a hazard.

The severe weather conditions over the latter part of our test route not only harmed the figures, but have also made comparison with other drawbar units difficult. Nevertheless, it can be seen that the big 223kW engine gives the 22.331 a real advantage compared with other drawbars which we have tested.

Over Carter Bar on the A68, for instance, the MAN was 37 seconds quicker than the Scania P92, and a whole 62 seconds ahead of the Daf 2500. On the first day of our test, the powerful MAN produced figures which trounced those of the lesser-powered Scania and Daf. Its average fuel consumption, for example, was just 31.67 litres/100km, compared with 35.62 litres/100km for the Daf and 37.8 litres/100km for the Scania. This was achieved at an average speed almost identical to that of the Daf, and over 1.5km/h faster than the Scania.

Even with the severe winds that beset this test, the MAN was some 2km/h quicker over our Scottish route than the Scania or the Daf, although that wind did play havoc with its fuel consumption. To put it in to context, however, this unit was not only quicker than its drawbar rivals, it was quicker and more economical than 32-tonne tractors such as the Mercedes-Benz 1628, despite having a much greater volume capacity.

It is clear that MAN's high power-toweight ratio of 7kW/tonne helps here — had the vehicle been a low-powered one, we might not have been so willing to let the performance and economy figures stand on their own merits.

• SUMMARY

The high level of power and torque developed by the MAN 12-litre turbocharged and charge-cooled engine is adequate to provide a lively performance for vehicles of 38 tonnes or more, but for the time being UK legislation continues to curtail the maximum weight of drawbar combinations irrespective of the number of axles on the road.

MAN's underfloor-engined chassis fits well into the Philips' concept but with such restricted ground clearance operators might be well advised to stick to major routes.

Where volume is concerned this style of vehicle is unsurpassed although the demount system inevitably detracts from payload potential. This configuration, however, does provide the opportunity of maximizing use.

Legislation in the UK clearly restricts its application and if the transport industry is to be competitive in 1992 changes will have to be made to the law to allow operation of such vehicles on equal footing with our European partners.

By Bill Brock