Fodens light cab is built from grp

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

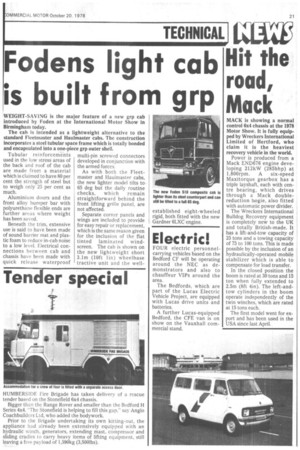

WEIGHT-SAVING is the major feature of a new grp cab introduced by Foden at the International Motor Show in Birmingham today.

The cab is intended as a lightweight alternative to the standard Fleetmaster and Haulmaster cabs. The construction incorporates a steel tubular space frame which is totally bonded and encapsulated into a one-piece grp outer shell.

Tubular reinforcements used in the low stress areas of the back and roof of the cab are made from a material which is claimed to have 80 per cent the strength of steel but to weigh only 25 per cent as much.

Aluminium doors and the front alloy bumper bar with polyurethane flexible ends are further areas where weight has been saved.

Beneath the trim, extensive use is said to have been made of sound barrier mat and plastic foam to reduce in-cab noise to a low level. Electrical connections between cab and chassis have been made with quick release waterproof multi-pin screwed connectors developed in conjunction with the armed forces.

As with both the Fleetmaster and Haulmaster cabs, the new lighter model tilts to 65 deg but the daily routine checks, which remain straightforward behind the front lifting grille panel, are not affected.

Separate corner panels and wings are included to provide for easy repair or replacement, which is the same reason given for the inclusion of the flat tinted laminated windscreen. The cab is shown on the new lightweight short 3.1m (10ft lin) wheelbase tractive unit and the well