Designers Should Relieve Dri ; of Gear-synchronizing Onus

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

By J. Pickles

IT appears remarkable that, apart from isolated instinges, the easy-change gearbox has made but little progress in the commercial-vehicle field, and that, in spite of the numerous changes of gear ratio which are made necessary by modern traffic conditions, picking up passengers and the satisfactory negotiation of hills, by far the greater number of models offered for sale to the public has been equipped with straight-toothed slidingmesh gearboxes of the type about which it has been said "It is brutal, but it works." The Wilson gearbox is, of course, used on many vehicles in considerable quantities, as is the Leyland torque converter, but both these components, judged by ordinary'standards, are rather complicated and expensive.

Accordingly, it is probable that, in the future, more interest may be taken tn the mechanisms of the privatecv world, where no average owner would tolerate a gearbox that was not equipped with some change-assisting mechanism. Most common, of course, is the synchronized-mesh gearbox, and a study of recent patents will show that interest in this type has not been completely ignored by commercial-motor engineers, The device most frequently used is of the constantload type, and comprises essentially a cone clutch which adjusts the speeds of mating wheels, thus enabling a quiet change to be made and at the same time eliminates the. need for double declutching, an operation which is no light matter to perform some hundreds of times a day against heavy clutch springs.

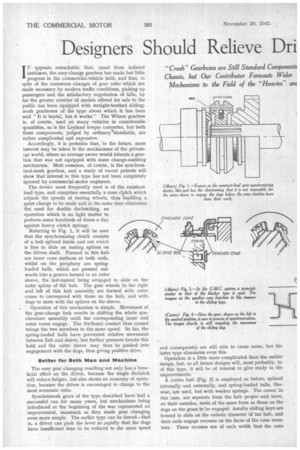

' Referring to Fig. I, it will be seen that the synchronizing clutch consists of a hub splined inside and out which is free to slide on mating splines on the driven shaft. Formed in this hub are inner cone surfaces at both ends, whilst on the periphery are springloaded balls, which are pressed outwards into a groove formed in an outer sleeve, the last-named being arranged to slide on the outer spline of the hub. The gear wheels to the right and left of this hub assembly are formed with outer cones to correspond with those on the hub, and with dogs to mate with the splines on the sleeve.

' Operation of this mechanism is simple. Movement of the gear-change fork results in shifting the whole synchronizer assembly until the corresponding inner and outer cones engage. The frictional contact thus caused brings the two members to the same speed. So far, the spring-loaded balls have prevented relative movement between liub and sleeve, but further pressure breaks this hold and the outer sleeve may then be pushed into engagement with the dogs, thus giving positive drive.

Better for Both Man and Machine The easy gear changing resulting not only has a beneficial effect on the driver, because the single declutch will reduce fatigue, but also shows an economy of operation, because the driver is encouraged to change to the most economic ratio.

Synchromesh gears of the type described have had a successful run for many years, but mechanisms being introduced at the beginning of the war represented an improvement, inasmuch as they made gear changing even more simple. The earlier type can be forced—that is, a driver can push the lever so rapidly that the dogs have insufficient time to be reduced to the same speed

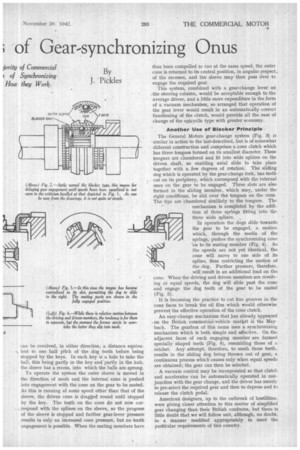

and consequently are still able .to cause noise, but the latter type eliminates even this. Operation is a little more complicated than the earlier design, but, as all future designs will, most probably, be of this type, it will be of interest to give study to the improvements. A centre hub (Fig, 2) is employed as before, splined internally and externally, and spring-loaded balls, likewise, are used, but with weaker springs. The cones, in this case, are separate from the hub proper. and have, on their outsides, teeth of the same form as those on the dogs on the gears to be engaged. Axially sliding keys are housed in slots on the outside diameter of the hub, and their ends engage recesses on the faces of the cone members. These recesses are of such width that the cone can be revolved, in either direction, a distance equivalent to one half pitch of the dog teeth before being stopped by the keys. In each key is a hole to take the ball, this being partly in the key and partly in the hub. the sleeve has a recess, into which the balls are sprung.

To operate the system the outer sleeve is moved in the direction of mesh and the internal cone is pushed into engagement with the cone on the gear to be mated. As this is running at some speed other than that of the sleeve, the driven cone is dragged round until stopped by the key. The teeth on the cone do not now correspond with the splines on the sleeve, so the progress of the sleeve is stopped and further gear-lever pressure results in only an increased cone pressure, but no tooth engagement is possible. When the mating members have thus been compelled to run at the same speed, the outer cone is returned to its central position, in angular respect, of the recesses, and the sleeve may then pass over to engage the required gear.

This system, combined with a gear-change lever on .the steering column, would be acceptable enough to the average driver, and a little more expenditure in the form of a vacuum mechanism, so arranged that operation of the gear lever would result in an automatically correct functioning of the clutch, would provide all the ease of change of the epicyclic type with greater economy.

Another Use of Blocker Principle The General Motors gear-change system (Fig. 3) is similar in action to the last-described, but is of somewhat different construction and comprises a cone clutch which has three tongues formed on its smallest diameter. These tongues are chamfered and fit into wide splines on the driven shaft, so enabling axial slide to take place together with a few degrees of rotation. The sliding dog which is operated by the gear-change fork, has teeth cut on its periphery, which correspond with the internal ones on the gear to be engaged. Three slots are also formed in the sliding member, which may, under the right conditions, be slid over the tongues on the cone. The tips are chamfered similarly to the tongues. The mechanism is completed by the addition of three springs fitting into the three wide splines. , In operation the dogs slide towards the gear to be engaged, a motion which, through the media of the springs, pushes the synchronizing cone on to its mating member (Fig. 4). As the speeds are not yet identical, the cone will move to one side of its spline, thus restricting the motion of the dog. Further pressure, therefore, will result in an additional load on the cone. When the driving and driven members are revolv ing at equal speeds, the dog will slide past the cone and engage the dog teeth of the gear to be mated (Fig. 5).

It is becoming the practice to cut fine grooves in the cone faces to break the oil film which would otherwise prevent the effective operation of the cone clutch.

An easy-change mechanism that as already appeared on the British commercial-vehicle marl‘et is the May bach. The gearbox of this name uses a synchronizing mechanism which is both simple and effective. On the

adjacent, faces of each engaging member are formed

specially shaped teeth (Fig. 6), resembling those of a ratchet. Any attempt, therefore, to mesh those teeth.

results in the sliding dog being thrown out of gear, a continuous process which ceases only when equal speeds are obtained; the gear can then be selected.

A vacuum control may be incorporated so that clutch and accelerator can be automatically operated in con junction with the gear change, and the driver has merely to prc-select the required gear and then to depress and to release the clutch pedal.

American designers, up to the outbreak of hostilities, were giving closer attention to this matter of simplified gear changing than their British confreres, but there is little doubt that we will follow suit, although, no doubt, in a manner modified appropriately to meet the particular requirements of this country.