BUS BODIES: Their Framework and Panelling.

Page 29

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

Some Important Considerations of the Materials Available and How They Can Best Be Used.

TTHel framework of the bus body is made of ash, both the homegrown and imported varieties of this timber being used. English ash is ideal for bodybuilding, because it has strength, toughness and elasticity combined, to a degree unsurpassed by any other timber. Although some body frames may be made entirely of it, this valuable wood is used principally for the More important parts, such as the pillars, waist-rails and bottom framework.

The side pillar is a frequently recurring item in a bus body. As .a pattern can be designed which will. be suitable for more than one size of body, some concerns prefen to buy, pillars already roughly sawn rather than purchase planks of different

shapes and sizes which will cut up with varying degrees of economy.

Imported ash, chiefly American, is used extensively, because it can be bought in " square-edged " planks (English ash has the bark on) of good length, which can be converted with little waste into cant-rails, seat-rails, bottom sides and so on. As a rule this timber is not so tough as home-grown ash, but if well selected it gives satisfactory results.

The Appeal of Imported Ash.

American and other imported varieties of ash make a special appeal to the bus builder, because they can be more readily obtained in long, straight planks than is the case with English ash. The need for this kind of plank tends to become greater owing to the increasing demand for large singledeckers. The curved hoopsticks or roofribs are often cut out of the solid. The ideal material to cut these from is naturally curved plank of hedge-grown English ash, .but, as the supply of such timber Is limited, sound timber, more or less straight grained, has to be used instead. The ends of the hoopsticks will be weak, according to the amount of " short " grain present. This is compensated by flitch-plating them.

If the roof camber be well arched at the ends it may be advisable to make the hoopstick in three portions. To obviate this bent timber is advocated.

Timber Well Suited to Bending.

Another useful quality of ash is that it is well suited for bending by steam. The wood so treated must be young and of first quality. When bent by experienced hands the timber should be as strong as a spliced member and lighter in weight.

Bent timber may also be used for the wheelarches, the framework of the rounded hind corners and the front corners of the roof. As bent timber tends to revert • to its original shape, the "stretchers," used to maintain its curved form, should be kept securely in position until the timber is about to be framed into the body.

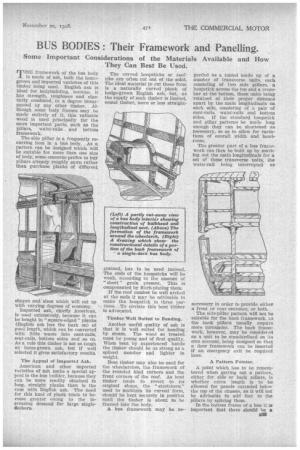

A bus framework may be re garded as a tunnel made up of a number of transverse Units, each consisting of two side pillars, a hoopstick across the too and a crossbar at the bottom, these units being 'retaiaed at their proper distance apart by the main longitudinals on each side, consisting of a pair of cant-rails, • waist-rails and bottom sides. If the standard hoopstick and pillar patterns be made long enough they can be shortened as necessary, so as to allow for variations of overall width and head_room.

The greater part of a bus framework can then be built up by mark, lug out the main longitudinals for a set of these transverse units, the waist-rail being interrupted as •

necessary in order to provide, either a front or rear entrance, or both.

The side-pillar pattern will not be suitable for the back framework, as the back pillars usually require more turnunder. The back framework, however, may be considered as a unit to be standardized on its own account, being designed so that a door framework can be inserted if an emergency exit be required here.

A Pattern Pointer.

A point which has to be remembered when getting out a pattern, either for side or back pillars, N whether extra length is to be allowed for panels extended below the top of the chassis, as it will not be advisable to add feet to the pillars by splicing them.

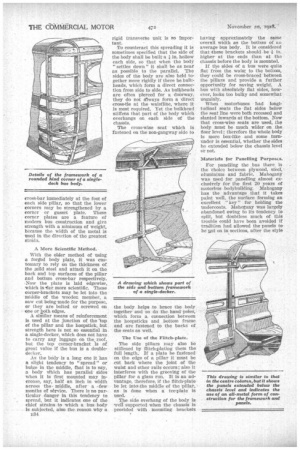

In the bottom frame of a bus it is important that there should be a B38

cross-bar immediately at the foot of each side pillar, so that the lower corners may be strengthened by a corner or gusset plate. These corner plates are a feature of modern bus construction and give strength with a minimum of weight, because the width of the metal is used in the direction of the greatest strain.

A More Scientific Method.

With the older method of using a forged body plate, it was customary to rely on the thickness of the mild steel and attach it on the back and top surfaces of the pillar and bottom cross-bar reepectively. -Now the plate is laid edgewise, which is ler more scientific. These corner-brackets may be let into the middle of the wooden member, a saw cut being made for the purpose, or they are bolted or screwed on one or both edges.

A similar means of reinforcement Is used at the junction of the top of the pillar and the hoopstick,.but . strength here is not so essential .in a single-decker, which does not have, to carry any luggage on the roof, but the top corner-bracket Is of great value if the bus is a doubledecker.

As the bdcly is a long one it has It slight tendency to " spread " or bulge in the middle, that is to say, a body v3hich has parallel sides when it is •first mounted may increase, say, half an inch ht width across themiddle, after a -few months of s4rvice. There is no particular danger in this tendency to spread, but it indicates one of the chief strains to which a bus body is subjected, also the, reason why a n34 rigid transverte unit is eo important, To counteract this spreading it is sometimes specified that the side of the body shall be built a I in. hollow each side, so that when the body "settles down" it shall he as near as possible to the parallel. The sides of the body are also held together more rigidly if there be bulkheads, which form a direct connection from side to side. As bulkheads are often pierced for a doorway, they do not always form a direct cross-tie at the waistline, where it is most required. Yet the bulkhead stiffens that part of the body which overhangs on each side of the chassis.

The cross-wise seat which is fastened on the non-gangway side to

the body. helps to brace the body. together and so do the. hand -poles,which form a, connection between the hoopsticks and bottom frame and are fastened to the hacks of the seats as well.

The Use of the Flitch-plate.

The side pillars may also be stiffened by flitch-plating them the full length.. If a plate be fastened on the edge of a pillar it must be cut back where the joint of the waist and Other rails occurs ; also it interferes with the greoving of the pillar for a glass run. It is an advantage, therefore; if the flitch-plate he let into, the middle of the pillar, as is done when a tee-plate is used. .

The side overhang of the body is -well supported when the chassis is provided with mounting brackets

having approximately the SarDe overall width as the bottom of an average bus body. It is considered that Aimee brackets should be * in. higher at the ends than at the chassis before the body is mounted.

If the sides of a bus were quite flat from the waist to the bottom, they could be cross-braced between the pillars and 'provide a further opportunity for saving weight. A bus with absolutely flat sides, however, looks looks too bulky and somewhat Ungainly.

When motorbuses had longitudinal seats the fiat sides below the seat line were both recessed and slanted inwards at the bottom. Now that cross-wise seats are used, the body must be much wider on the door level; therefore the whole body is more box-like and some turn under is essential, whether the sides be extended below the chassis level. Or not Materials for Panelling Purposes.

For panelling the bus there is the choice between plywood, steel, aluminium and fabric. Mahogany was used for panelling almost exclusively for the first 20 years of motorbus bodybuilding. Mahogany has the advantage that it takes paint well, the surface forming an excellent " key " for holding the underco-ate. Mahogany was largely abandoned owing to its tendency to split, but doubtless much of this trouble could have been avoided if tradition had allowed the panels to be p.ut on in sections, 'after the style of the metal panel. The mahogany panel is also light in weight.

Sheet steel is now the most popular panelling material, because it is strong and cheap. Waterproof plywood was much in vogue a few years ago and, owing to its being the strongest material in comparison with its weight, should have ousted steel, but, in some instances; moisture penetrated at the edges and caused the plies to bulge. Plywood is extensively used, however, for inside casing boards, whilst the merits of plywood, armoured with a sheet of aluminium or steel, should not be overlooked.

For a high-class lightweight body,

aluminium is often employed. The extra cost over steel is not so great as at first appears, because where rounded corners and domed back panels occur, the aluminium entails less labour in connection with beating it into shape.

The fabric-panelled bus is so far a rarity, and this is a method of finish which has yet to be developed. From the point of view of safety, it would no doubt be advisable to have a solid backing to all fabric panels, an instance where plywood could be used.

If the bus proprietor be inclined to favour the all-metal form of construction lie will regard the average

bus 'not as a wooden structure, but as a composite one of wood and metal. He will admit that the wood predominates, but the metal used is of vital importance for strengthening the body without undue weight, and allowing the various parts oif the wooden framework to 'be lightly proportioned.

The body, which is framed and panelled in metal is not so revolutionary a step as might at first appear, but is rather the logical outcome of recognizing the fact that, as metal is the more important material, even in a composite body, it may reasonably be employed without the aid of wood.