REMEDIES FOR STEAM BOILER TROUBLES.

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

The Continuation and Conclusion of an Article Begun in Last Week's Issue Dealing with the Means for Reducing the Cost of Boiler Maintenance.

THE AIM of this article, the first portion of which appeared in the last issue of The Commercial Motor, is to assist those responsible for the maintenance of steam-wagon boilers to reduce the cost thereof to a minimum. The boiler, as we then said, is a component that very rarely fails, yet is responsible for the greater proportion of the costs of repair and upkeep of a steam wagon. In the first portion of the article we dealt in the main with leaking tubes, the causes of the leakage, the manner of preventing it to some extent; and the methods of repair and replacement. We also dealt with the need for constant washing out of the boiler, and the best method of cleaning out and the removal of scale, and, incidentally, we gave details of a method of preventing the formation of scale.

We went on to deal with fusible plugs, the reason why they burn out, their replacement and the way in which a boiler plate should be treated should it have become thin around the plug hole. We concluded the first portion of the article with a reference to cracks occurring in the-firebox plates, showing where these cracks usually appear and their causes.

The old-fashioned remedy for repairing a crack was the "boiler-maker's stitch," i.e., a, series of screwed copper plugs running into one another along the whole length of the crack. It is much quicker and cheaper, however, to have a crack electrically welded, a process which is now in use all over the country. They should never be welded by oxy-acetylene, as this process is not suitable for boiler work.

The Bulging of Firebox Plates.

Another defect sometimes found in fireboxes is a bulge in the plate. This is caused by the accumulation of dirt or scale, which results in overheating of the plate and consequent stretching under pressure. This defect is more often found in square fireboxes, where the flat plates are supported by stays which occasionally break. In this case, the bulge can be taken out in the following manner. Remove the stays round the bulge and fit a bolt into the stayhole nearest the centre ; then heat the plate and hammer it etraight, tightening up the bolt at the same time. With a round firebox where no stays are fitted, when a bulge occurs it should be carefully 4356 examined, and if the plate is damaged it should be repaired by electric welding.

The stays in any firebox should be periodically examined, by tapping them with a hammer, to see if any are broken; a sound stay will give a clear ring, but one broken or cracked will give a dull sound. Defective stays should be replaced as soon as poesible or the plate will bulge. The heads of these stays are also liable to leak, and if so should be immediately caulked._

Another frequent defect with boilers fired from the side or end is leakage round the firedoor joint, caused by the accumulation of mud .and scale, or by the firedoor being left open too long. If the defect be slight, it can be repaired by caulking the joint; but if this does not remedy the defect it is best repaired by electric welding.

With the class of workmanship now put into steam boilers leakage of a riveted seam. does not often occur; if it does, the seam should be immediately caulked to prevent the accumulation of scale in the joint.

A great deal of trouble is sometimes experienced in keeping mud-hole doors tight, and because of this drivers will not remove all the doors when washing out. This is invariably due to the joint ring not being of the proper size or being too pliable and squeezed out when tightening up. If too much pressure is put on the nut the bolt or the bridge bar is liable to be broken. The door itself should be a good fit in the inudhole, and the joint ring should be the same width as the lip on the door and slightly smaller in size so that it has to be stretched a little to get it on. A joint ring of the proper size can be used again and again, by simply smearing it with grease and graphite every time it is removed.

Very little trouble is experienced with safety valves beyond occasional leakage, which can be remedied by grinding in the valves with a little fine grinding paste. They also occasionally require adjusting to blow off at the correct pressure. When this is done care must be taken that the ferrules are the correct length, so that when the nut is tightened full home the spring is at the correct tension. Packing washers should never be used for these ferrules, but instead a solid ferrule of the exact length required. When testing safety valves, the steam

pressure should be rising, for when it is falling the valves are liable to stick and remain open below the set pressure. A smart tap on the valve lever with a light article will stop the valves blowing. It is essenlial, of course, that the pressure gauge should always give the correct reading, but csiless a

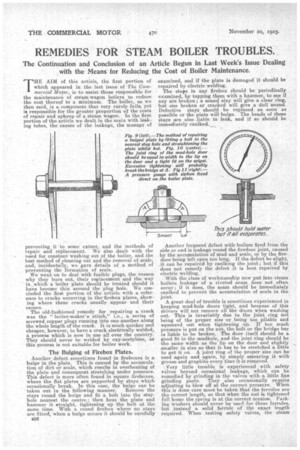

good make is used they are liable to get out of order and give a low reading. The simplest test is te note whether the pointer returns to zero when the boiler is cod, tapping the gauge smartly with the fingers as one would a bareineter for they sometimes stick at low pressure, The best plan is to have a reliable test gauge, which can be fixed by a union to any suitable connection (for instance, the-injector steam valve), the working gauge being compared therewith at full steam pressure. The chief cause of pressure gauges getting out of order is the want of a proper siphon. Sometimes the gauge is fixed direct on the barrel of the boiler with a siphon arrangement, as shown in Fig. II. This is a very poor arrangement, for, the siphon being in the steam space, will not hold water, consequently the gauge becomes overheated and the internal mechanism distorted. The best 'arrangeinent is to ' fix the gauge some .distance from the boiler connection, and to Use a copper siphon pipe as shown in Fig. 12. For the gauge joint a lead washer about 3-32 in. thick will be found to give best results, care being taken not to screw up too hard, or the hole in the washer will closeup.

Why Water Gauges Give Trouble.

With water gauges the chief trouble is breakagesof the glass, unless the reflex pattern is used.. in the majority of cases, breakage is due to the top and bottom fittings not being in line. They should be tested by using a straight steel rod of the .same diameter as the glass, and the fittings reset if not in line. Glasses should also be of the correct length, i.e., they should project at the top beyond the seating for the packing when resting' on the bottom face. They should also be of the correct diameter, and fitted in from the top. Either plain or cone sings will give satisfactory results.

Another cause of trouble is furring up of the check valves. Very often, through neglect: the. hole in the boiler becomes choked to such an extent that it is only about in. in diameter, and the Beale is so hard that it has to be drilled out. It is no wonder that under these conditions the injector will not work, or the feed-pump hammers and might. even burst the delivery pipe. When using very hard water, it is advisable once a month to remove the check valves and to clean nut the holes.

The check valves should be kept well seated by grinding in occasionally2 for any leakage back to the water tank causes the injector to refuse duty. The. pump check valve requires most attention, owing to the fact that it is continually beating on the seat. The lift should not be allowed to become too high. This is prevented by reducing the thickness of the collar on the cap as the seat wears.

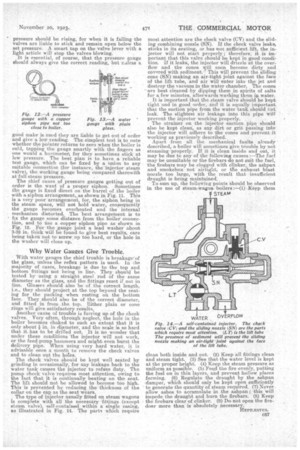

. The type of injector usually fitted on steam wagons is complete with all the necessary fitting (except steam valve), self-contained within a single casing, as 'illustrates in Fig. 14. The parts which require

most attention are the check valve (CV) and the sliding combining nozzle (SN). If the cheek valve leaks, sticks in its seating, or has not sufficient lift, the injector will not start properly ; therefore, it is important that this valve should be kept hi good condition. If it leaks, the injector will drizzle at the overflow and the cones will soon become dirty and covered 'with sediment. This will prevent the sliding cone (SN) making an air-tight joint against the face of the lift tube, and air will enter into the jet and destroy the vacuum in the water chamber. The cones are best cleaned by dipping: them in spirits of salts for a few minutes. afterwards washing them ip. water.

It is iMportant that the steam valve should be kept tight and in good order, and it is equally important. that the suction pipe from the water tank should not leak. The slightest air leakage into this pipe will' prevent the injector working. properly. The strainer on, the injector -suction pipe should also be kept clean, as any dirt or grit passing into the injector will adhere to the cones and prevent it working as previously described.

Apart from all the mechanical faults already described,a boiler will -sometimes give trouble by not steaming properly. E. it is clean inside and out, it may be due to any of the following causes :—The fuel may be unsuitable or the firebars do not suit the fuel, the firebars may be clogged with clinker, the ashpan and smokebox not airtight, or the exhaust blast nozzle too large, with the result that insufficient draught is being maintained.

To sum up, the following points should be observed in. the use of steam-wagon. boilers :—(1) Kepi) them clean both inside and out. (2) Keep all fittings clean and steam tight. (3) See that the water level is kept at the proper height. (4) Keep the steam pressure as uniform as possible. (5) Feed the fire evenly, putting the fuel on in thin layers, and prevent hollow places forming. (6) Regulate the draught by the ashpan damper, which should only be kept open sufficiently to generate the quantity of steam required. (7) Never allow ashes to accumulate in the ashpan; this will impede the draught and burn the firebars. (8) Keep the firebars clear of clinker. (9) Do not open the firedoer more than is absolutely necessary.

ITEPiLESTITS. c57