MAKING BEST USE OF THE FORD.

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, which will Appeal to the Owner, Driver, and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck wherever they 'are employed for commereial purposes, we endeavour to deal with the subject from every view-point, so that the advice given will appeal to the owner, driver, maintenance engineer, or mechanic. Valuable sources of information are being tapped for this purpose, and it should be understood that the advice given will be derived from those with an intimate knowledge of the subject. We shall welcome for inclusion among the hints those which have proved of value to individual users and will make suitable remuneration for any published. What we desire are the results of practice.

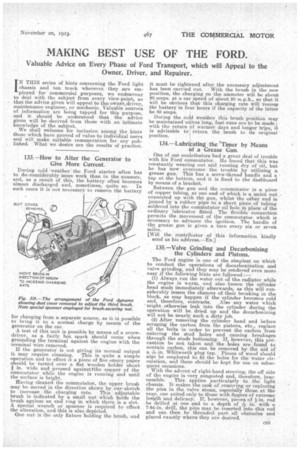

133.—How to Alter the Generator to Give More Current.

During cold weather the Ford starter often has to do,considerably more work than in the summer, and, as a result of this, the battery often becomes almost discharged and, sometimes, quite so. In such cases it is not necessary to remove the battery

for charging from a separate source, as it is possible to bring it to a normal charge by means of the generator on the car.

A test of this unit is possible by means of a screwdriver, as a fairly hot spark should occur when grounding the terminal against the engine with the terminal wire removed.

If the generator is not giving its normal output it may require cleaning. This is quite a simple operation and to effect it a piece of fine emery paper should be turned over a flat wooden holder about

in. wide and' pressed against tthe copper of the commutator while the engine is running and until the surface is bright.

Having cleaned the commutator, the upper brush may be moved in the direction shown by our, sketch to increase the charging rate. This adjustable brush is indicated by a small nut which holds the brush against an end ring in which there is a slot. A special wrench or spanner is required to effect the alteration, and this is also depicted.

One nut is the only fixture holding the brush, and

it must be tightened after the necessary adjustment has been carried out.. With the brush in the new position, the charging on the ammeter will be about 20 amps. at a car speed of about 20 m.p.h., so that it Will be obvious that this charging rate will recoup the battery in four hours if the capacity of the latter be 80 amps.

During the cod weather this brush position may be maintained u less long, fast runs are to be made; with the return f warmer days and longer trips, it is advisable to return the brush to its original position.

134.—Lubricating the 4Timer by Means Of a Grease Gun.

One of our contributors had a great deal of trouble with his Ford commutator. He found that this was constantly wearing out and running dry of oil, but he has now overcome the trouble by utilizing a grease gun. This has a screw-thread handle and a tap at the bottom, and it is fixed to the dashboard by means of a bracket.

Between the gun and the commutator is a piece of copper tubing, at one end of which is a, union nut connected up with the gun, whilst the other end is joined by a rubber pipe to a short piece of tubing soldered into the commutator oil hole in place of the ordinary lubricator fitted. The flexible .connection permits the movement of the commutator which is necessary to advance the, ignition. The handle of the_ grease gun is given a turn every six or seven miles.

[Will the contributor of this information kindly send us his address.—En]

135.—Valve Grinding and Decarbonizing the Cylindersand Pistons.

The Ford engine is one of the simplest on which to conduct the operations of decarbonization and valve grinding, and they may be rendered even more easy if the following hints are followed :—

(I) Always run the water out ol the radiator while the engine is warm, and also loosen the cylinder head studs immediately afterwaerds, as this will considerably lessen the chances of their breaking in the block, as may happen if the cylinder becomes cold and, therefore, contracts. Also any water which

' might otherwise leak into the cylinder during. the operation will be dried up and the deca,rborazing will not be. nearly such a dirty job.

(2) After removing the cylinder head and before scraping the carbon from the pistons, etc., replace all the bolts in order to prevent the carbon from entering the stud holes and causing breakages throu.gh the studs bottoming. If, however, this precaution be not taken and the holes are found to contain carbon, this can be removed by the aid of a Whitworth plug tap.. Pieces of wood should also be employed ta fit the holes for the water circulation, and these should be kept for use on subsequent occasions.

With the advent of right-hand steering, the off side of the engine is very congested and, therefore, inac

cessible. This applies particularly to the light chassis. It makes the task of removing or replacing the pins in the valve stems, especially those at the rear, one suited only to those with fingers of extreme length and delicacy. If, however, pieces of tin. rod be drilled at one end to a depth of g in. with a 7-64-in, drill, the pins may be inserted into this rod and can then be threaded past all obstacles and placed exactly where they .are desired.