A BRITISH-BUILT TRACTOR-BUS.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

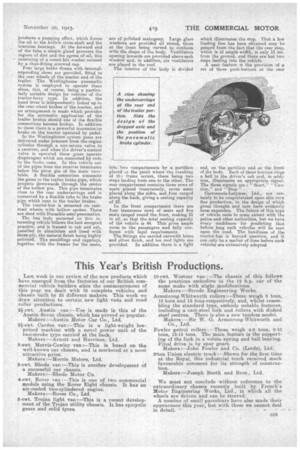

The Carrosserie-Latymer Tractor-lorry Fitted with a Single-deck Bus Body, Four-wheel Steering and Pneumatic Brakes.

IT IS SAFE to say that. a new production of the well-known firm of Carrosserie-Latymer, -IAA, will prove a centre of immense interest at the forthcoming Show. This is a tractor-lorry fitted with a •44-seater single-deck bus body and incorporating many original and novel feateres. Four-wheel steering is employed; the -rearmost pair of wheel; being mounted on a turntable and auto

matically controlled by a patented system which was fully described in The Commercial Motor of July 24th.

The tractor portion of the vehicle is a type SK5 Karrier, the engine of which develops 50 h.p. at 1,000 r.p.m. The driver's seat and the -controls are placed over and alongside the engine, which brings the cal, well forward and provides plenty of room for the turntable and the front of the trailer. The wheelbase of the tractor is 10 ft. 5 ins. The trailer portion follows the well-known Carrosserie-Latymer practice, and this and the body were entirely constructed at the Pamber Street 'Works of the company.

The frame of the trailer portion is cranked to give a low loading line from the back of the tractor rearwards, and at this point adequate bracing is pro vided by steel gusset plates and duplicated channels. The main turntable. connecting the tractor and trailer is 'designed to give a lot, loading line and comprises a central bolster block and bronze thrust ring ; these Nils carry the load and relieve the pin of all shear stresses. The pin itself is 21 ins. in diameter and is bored to permit of the passage of the wiring and the pneumatic

piping for the lighting and the brakes respec7tiva1y.

Surrounding the central bolster are two large circular plates secured to the tractor and trailer respectively. These Lot-in a turntable giving the vehicle great stability, and the surfaces are adequately lubricated by means of a large greasar communicating with holes and grooves in the working parts. The rearmost axle is mounted on an undercarriage which swivels on the trailer under the control of an automaticoperating gear which will be mentioned later. This undercarriage is on a turn. table similar in design to that already described, an excellent feature being the clips provided to prevent the circular plates from separating. The tendenoy to separation occurs when the rearmost wheels hit an obstacle, and this is pre

vented by the clips, each of 'which covers an arc of about 00 degrees. Here again the lubricating system is ' excellently carried out and stability is assured by the design.,

A feature of interest in the rear axle is the way in which a cranked effect is obtained, Without appreciably limiting the width of the trailer. The axle proper fits into steel castings placed at each end, which are box-shaped and form the housings for the semi-elliptic leaf springs. From these castings stub axles project at 4 higher level, which carry the wheel. The construction is clearly shown in one of the sketches reproduced.

The control of the rearmost axle is very ingenious and effective. Four shaped plates bolted to the rear end of the tractor frame carry a large universal joint, to which a longitudinal rod is secured. This rod passes through a tube which is secured to a cross-piece. The cross-piece is in turn mounted on trunnions on the rear undercarriage. The position of the joints is such that when the two _portions of the Vehicle are set at an angle the rod working in the tube has the effect of inclining the: rear-. most axle relative to the trailer, so making the rearmost . wheels track correctly with the ether four.

This arrangement has great advantages 'in that it imposes no extra work upon the driver and, furthermore, no move-, ment of the rearmost axle can take place until the two portions of the vehicle are set at an angle. Consequently, starting awa,y from the kerb and manceuvring into the road presents no difficulty. The, minimum turning circle is 20 ft radius.

Although the principle of this steering device has remained unaltered since it was last described in this journal, several ingenious features have been incorporated in the present design. There is a clearance space between the rod and tube through the greater part of the length, a bush being providdd at the front cud of the tube,and to the rear. end of the rod a plug is Secured, which is a sliding fit. The rear and of the tube is blanked off. Provision is made for oil to be supplied to the rear end of the tube and the to and fro motion of the rod when the vehicle is 'cornering

produces a pumping effect, which forces the oil to the hollow cross-shaft and the trunnion bearings. At the forward end of the tube a simple gland prevents the ingress of dirt and the egress of oil, this consisting of a coned felt washer secured by a close-fitting screwed cap. Four large brake drums with internalexpanding shoes are provided, fitted to 7 the rear wheels of the tractor and of the • trailer. The Westinghouse pneumatic system is employed to operate these shoes, this, of course, being a parbicnlarly suitable design for vehicles of the tractor-lorry type. In addition, the hand lever is independently linked up to the rear-wheel brakes of the tractor, and an arrangement is made which provides for the automatic application of the trailer brakes should one of the flexible connections become broken. In addition to these there is a powerful transmission brake on the tractor operated by pedal. In the Westinghouse system gases are delivered under pressure from the engine cylinder through a non-return valve to a receiver, and when the driver's control valve is operated these gases operate diaphragms which are connected by rods to the brake cams. In this vehicle one of the pipes from the receiver terminates below the pivot pin of the main turntable. A flexible connection transmits the gases to the trailer brake pipe, which projects downwards through the centre of the hollow pin. This pipe terminates close to the rear undercarriage and is connected by a flexible tube to the brake ' pipe which runs to the trailer brakes.

The tractor-bus is mounted on cast. steel wheels with hollow spokes. These are shod with_Ducasble semi-pneumatics. The bus body mounted on this interesting vehicle follows the best accepted practice, and is framed in oak and ash, panelled in aluminium and lined with three-ply, the natural finish being highly polished. The mouldings and cappings, together with the frames for the seats, are of polished mahogany. Large glass windows are provided all round, those at the front being curved to conform with the shape of the body. Ventilators opening inwards are provided above each window and, in addition, six ventilators are placed in the roof.

The interior of the body is divided

into two compartments by a partition placed at the point where the cranking of the frame occurs, there being two steps leading from one to the other. The rear compartment contains three rows of seats placed transversely, seven seats placed along the sides, and •four ranged along the back, giving a seating capacity of 23.

In the front compartment there are four transverse rows of seats and five seats ranged round the front, making 21 in all, so that the-total seating capacity of the vehicle is 44. This gives ample room to the passengers and fully conforms with legal requirements. The fittings are carried outowith brass and silver finish, and ten roof lights are provided. In addition there is a light which illuminates the step. That a low loading line has been obtained may be ganged from the fact that the rear step, which is of ample-width, is only 13 ins. from the ground, and there are but two steps leading into the vehicle. A neat feature is the provision of a set of three push-buttons at the rear

end, on the partition and at the front of the body. Each of these buttons rings a bell in the driver's cab and, in addition, illuminates an appropriate signal. The three signals are : " Start," "Caution," and "Step." Carrosserie-Latymer, Ltd., are certainly to be congratulated upon this very. fine production, in the design of which great thought. and care have evidently been expendee. The future of this type of vehicle rests to some extent with the police and other authorities, but we have every confidence for predicting that before long such vehicles will be seen upon the road. The handiness of the tractor-bus is beyond question, and it can only be a matter of time before such .vehicles axe extensively adopted