A Clutch Designed• for High Torque

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

ACLUTCH intended to be used between the output member of a torque-converter and its gearbox forms the subject of patent No. 615,507, which comes from Brockhouse Engineering (Southport), Ltd., and A. Gatiss, both of Rufford Road, Crossens, Southport. In this position, the torque is much greater than that of the engine, and the parts would have to be unduly large if the normal type of friction clutch were merely scaled up. In the present scheme, the friction members are of normal size and type, but an additional dog clutch is incorporated to take over the drive as soon • as synchronism has been established.

Referring to•the drawing, which shows the clutch in the free position, the friction members work in the usual way, being pressed into driving contact by springs (I) acting on a presser plate (2). The latter, however, cannot move into engagement because it is prevented by the presence of a ring of balls (3) which are trapped by the outer casing. The outer casing, it should be noted, is the operating member, being movable endways by a fork-receiving ring (4).

A set of dog-teeth(S) on the driving member is-in line With a similar set (6) on the "driven part, but in the position shown, they 'are unconnected. To engage the clutch, the outer casing is moved to the right, an action which first .releases the balls into the larger diameter (7) and so allows the presser plate to engage the friction plates. Continued movement of the outer casing then brings its long dog-teeth (5) into engagement with set 6 and a positive connection is thus established.

A NEW SWASEI-PLATE ENGINE

THE swash-plate or wobble-crank seems to have an irresistible attraction for inventors, and pa ten t No. 616,101 shows the latest suggestions on the subject. The patentee is I. Wooler, Willow Bungalow, West End

Road, Ruislip, an inventor who has in the past 'designed many novel power units.

To silk the general outline, the crankshaft has an inclined crankpin (1) ,34 upon which runs the wobble-plate (2). The pistons are connected to this j?)late via connecting-rods (3) fitted with a ball-joint at each end. Note that the pistons are in opposed pairs, each pair utilizing a common combustion space (4) between them. The wobble-crank mechanism is, of course, duplicated in the other end in casing 5.

The chief point of the 'patent is the means for operating the valve gear. This is driven by a pinion (6) on the crankshaft which drive, via idler pinion; an internally toothed ring (7). The ring is provided with cam surfaces on its two end edges, and these work the valves via push-rods and rockers, not shown.'

The patent also covers the principle of moving one wobble-plate to or from the other one, thus giving a variable compression, which would be of use in an aircraft engine that has to function at various altitudes.

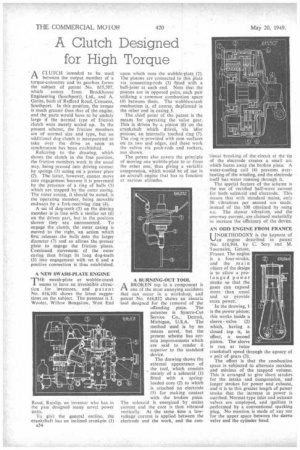

A BURNING-OUT TOOL

ABROKEN tap in a component is one of the most annoying accidents that can occur in a workshop, and patent No. 616,832 shows an electric tool designed for the removal of the offending piece. The patentee is Syncro-Cut Service Co., Detroit, Michigan, U.S.A. The method used is by no means novel, but the present scheme has certain improvements which are said to render it superior to the standard device.

The drawing shows the external appearance of the tool, which consists mainly of a solenoid (I) fitted with a springloaded core (2) to which is attached an electrode (3) for making contact with the broken piece. The solenoid is energized by mains current and the core is thus vibrated vertically. At the same time a lowvoltage •current is applied between the electrode and the work, and the con tinual breaking of the circuit at the tip of the electrode creates a small arc which burns away the broken piece. A water-cooling coil (4) prevents overheating of the winding, and the electrode itself has water running through it.

The special feature of the scheme is the use of rectified half-wave current for both solenoid sand electrode. This means that with standard mains, only 50 vibrations per second are made, instead of the 100 obtained by using a.c. The slower vibraticin, and the one-way current, are claimed materially to increase the efficiency of the device.

AN ODD ENGINE FROM FRANCE

UNORTHODOXY is the keynote of an engine described in patent No: 616,944, by C. Sery. and M. Tournaire, Grasse, France. The engine is a four-stroke, and the main object of the design is to allow a prolonged power Stroke so that the gases can expand more than usual and so provide extra power.

In the drawing, 1 is the power piston; this works inside a sleevevalve (2) which, having a closed top is, in effect, a second piston. The sleeve is run at twice crankshaft speed through the agency of a pair of gears (3).

The effect is that the combustion space is subjected to alternate maxima and minima of the trapped volume. This is arranged to give short strokes for the intake and compression, and longer strokes for power and exhaust,. and it is to this greater length of power stroke that the increase in power is ascribed. Normal-type inlet and exhaust valves are employed, and ignition is performed by a conventional sparking plug. No mention is made of any use for the upper space between the sleeve valve and the cylinder head.