HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Cet the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble

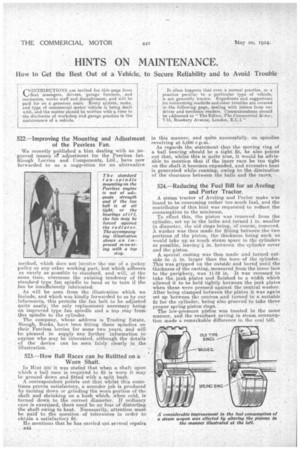

.522.—Improving the Mounting and Adjustment of the Peerless Fan.

We recently published a hint dealing with an improved means dr adjustment for the Peerless fan. Slough Lorries and Components, Ltd., have now forwarded to us a suggestion for an alternative method, which does not involvethe use of a jockey pulley or any other working part, but which adheres as nearly as possible to standard, and will, at the same time, overcome the existing tendency of the standard type fan spindle to bend or to turn if the fan be insufficiently lubricated: As will be seen from the illustration which we include, and which was kindly forwarded to us by -our informants, this permits the fare belt to be adjusted quite easily, the only replacement necessary being an improved type fan spindle and a top stay from this spindle to the cylinder.

The company, whose address is Trading Estate, slough, Bucks, have been fitting these spindles on their Peerless lorries for some two years, and will be pleased to supply any further information to anyone who may be interested, although the details of the device can be seen fairly clearly in the illustration.

523.—How Ball Races can be Refitted on a Worn Shaft.

In Hint 500 it was stated that when a shaft upon which a ball race is required to fit is worn it may be ground down and fitted with a split bush. A correspondent [Mints out that whilst this sometimes proves satisfactory, a sounder job is produced by turning down or grinding the worn portion of the shaft and shrinking on a bush which, when cold, is turned down to the correct diameter. If ordinary care is exercised, there need be no fear of distorting the shaft owing to heat. Necessarily, attention must be paid to the question of tolerances in order to obtain a satisfactory fit. He mentions that be has carried out several repairs . ..544

in this manner, and quite successfully, on spindles revolving at 5,000 r.p.m, •

As regards the statement that the moving ring of a ball bearing should be a tight fit, he also points out that, whilst this is quite true, it would be advisable to mention that if the inner race be too tight on the shaft it becomes expanded, and excessive heat is generated while running, owing to the diminution of the clearance between the balls and the races,

524.—Reducing the Fuel Bill for awAveling and Porter Tractor, A steam tractor of Aveling and Porter make was found to be consuming rather too miteh fuel, and the contributor of this .hint was requested to reduce the consumption to the minimum. . To effect this the piston was removed from the cylinder, set up in the lathe and turned 1 in. smaller in diameter, the old rings being, of Course, removed. A washer was then made for fitting between the two portions of the piston, the thickness being such as would take up as much steam space in thc cylinders as possible, leaving-i in. between the cylinder cover and the piston.

A special casting was then made and turned outside to A in, larger than the bore. of the cylinder. This was gripped on the outside and bored until the thickness of the casting, measured from the inner face to the periphery, was 11-32 in. It was recessed to take the junk plates and 'finished to a width which allowed it to be held tightly between the junk plates when these were pressed against the central washer. After being clamped befvbreen the plates it was again set up between the centres and turned to a suitable fit for the cylinder, being also grooved to take three proper spring piston rings.

The low-pressure pisfon was treated in the same manner, and the resultant saving in steam, consumption made a remarkable difference in the coal bill.