TECHNICAL FEATURES AT THE LEIPZIG• FAIR.

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

A Continuation of Our Review of the Developments in the German Heavy-vehicle Industry. Pointers in the. Design of Important Units.

OWING to the pressure on the space at our disposal in our issue of last week, and although we gave more than 12 pages to the subject, there was so much of interest to be said about the commercial-vehicle exhibits at the Leipzig Fair that we are now devoting still further space to the mEtter.

Types of Universal Joint.

One of the most popular types of universal joints at present employed on German vehicles is that consisting of rubberized canvas links, each link haying a concealed insert of stranded wire. It is obvious that in this joint some of the links are in compression and some in tension, but, apparently, it proves quite efficient Examples of the links employed were to be seen on vone of the stands in the gallery at the Corn-• mercial Vehicle Exhibition at Olympia, but, so far, we have not heard of their being adopted on actual vehicles.

For clutch shafts, etc., where there is but little movement the most popular form of joint appears to be the laminated steel.

In the Daag passenger chassis a coupling of this class is accommodated inside the internal cone clutch—a somewhat unusual position.

Where couplings of the Hardy type are employed these are usually very massive, some having as many as six distinct discs.

Enclosed all-metal universal joints are also used to a considerable extent, Particularly where the movement is likely to be fairly great. Such joints are usually of large size, and we saw very few comparable in their dimensions with the neat Spicer and other all,metal types utilized to such a largo extent on British vehicles.

Chassis Lubrication.

The need for accessibility in chassis lubrication is being generally recognized, such normally inaccessible parts as the spherical seatings for the forward end of torque tubes usually having pipes leading to one side of the chassis where is situated an oil reservoir Or greaser. Several chassis were equipped with the Bowen system of centralized lubrication. For this there were usually two Bowen reservoirs on the bonnet side of the dash, plungers projecting through to the driver's side.

We did not notice a single example of the wick-feed type, such as the Alcyl.

The employment of batteries of Tecalemit or other lubricators is not so apparent as in British vehicles, although in one example, the 3i-ton Daimler-Benz, there are six nipples mounted• in a row on the rear axle cover. These, of coarse, supply lubricant only to the axle and those parts immediately connected with it.

Tendencies in Braking.

It is apparent that the vaeuurl servo of the Dewandre pattern, which in Germany is built under licence by Bosch, is gaining considerable popularity and is competing successfully with the Knoor air-pressure system which only a few years ago practically had the field to itself—at least, for the heavier classes of vehicle. Thee 1i-floor system involves the employment of an auxiliary air pump which, in the bigger vehicles, is of considerable size, as in the case of the Daag, the pump in this vehicle being mounted above and to the left of the centre of the gearbox. There is one particular advantage in the Knoor system, and that is it lends itself to the more efficient braking of trailers, and in Germany it would appear that even more use is made of the trailer than in this country.

While on the subject of trailers we may refer to a peculiarity found in most

trailers of German make. This is the small cab mounted high above the front of the body in a manner closely resembling the form of construction utilized on German railway trucks. Where power brakes are not employed this cab is apparently provided for a brakesman who can also net as a loader.

So common has four-wheel braking now become that at Leipzig it was a matter of difficulty to find vehicles pot so equipped.

In the main tl operating mechanism has been simplified, and there is little which can be criticised in this direction, although the compensating mechanism is sometimes complicated, as is the case in a pattern which we illustrated last week in connection with the Henschel. In this method three short whipple-trees are employed and the scheme involves the use of something like 14 working joints, any of which may wear and eventually cause rattle.

In nearly every case we observed that the brake shoes were well protected from mud and dirt, although, in some instances, this was done at the expense of accessibility.

Dual-purpose Vehicles.

We wore rather surprised at the sparsity of vehicles designed to fulfil more than one function. These were practically confined to open touring cars in which the rear seats and upholstery can be detached, leaving a metalllined body. We saw only two or three examples even of these, one being a Hansa-Lloyd with neat double rear doors, and the other shown by Otto Kuhn, which was all-steel lined, including the floor. This had a drop AOboard instead of double doors. Both of these vehicles could hardly be distinguished from ordinary touring cars with the upholstery in position, particularly as the hood, when folded down, served to conceal the doors or tailboard, Which, of course, follovved the bulbous asntour of the back of the vehicle.

As an example of prices, it may be mentioned that the Kuhn vehicle, which is of 10 h.p., is marketed in Germany at approximately £265.

Rear-axle Design.

There were signs of an increased interest being taken in the development of worm gearing, but this was chiefly of the overhead type and, we believe, in most instances, cut on machines of British manufacture. There were still,

however, many examples of the doublereduction axle of the bevel-and-spur pattern, whilst the Daimler-Benz retained its dual-type axle with a first reduction by bevel gears and si final reduction by spur gears within the wheels. A similar type of axle was also employed on the Durkopp 5-tonner: Where worm drive is employed, the axle casing is usually of the built-up type, as in the Nacke, for which, incidentally, two underneath tie-bars are provided.

One of the favourite forms of casing is the banjo. This is employed with the banjo vertical, horizontal or. at an angle, the last position being utilized in the Vomag„ which has 'a double-reduction gear. In the N.A.G.-Presto a curious form of double-reduction axle is -employed. In this the forward portion of the casing is supported in a channelsection cress-bracket, the ends of which

• are secured in the channel-section sides of a triangulated torque member which ends in a torque ball.

A popnlar method of taking the torque is by torque tube and spherical joint. I n some cases the construction is extremely massive, whilst in the vehicles designed for comparatively light loads the torque tubes are of great length, being usually built in two sections bolted together with a concealed hearing for the propeller shaft at the point of juncture, a lubricating nipple being almost always provided here. The reason for the long tubes is that in the lighter vehicles the engine and gearbox are usually built as a unit,

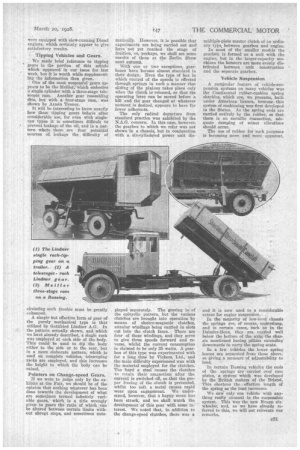

and by taking the The spring-suspension system employed on the new torque tube right up Mannesmann Maiag rigid frame sixwheeler. to the back of the Note the large transmission-hrake drum in front

gearbox the drive is of the right-angle drive.

totally enclosed for its

whole length. The method also obviates the use of more than one universal joint.

Sprag Devices.

A great ninny vehicles of German make are still equipped with the old form of dig-in triangulated sprag. Most of these sprags are mounted on the rear-axle casings, but in a few instances they are carried on cross-menabers and situated practically amid

ships. Sprags of this type are not very satisfactory, as they are usually net dropped until a vehicle begins to run backwards and, if they dig in then, are frequently jumped. It may be that, situated centrally, the load would be greater and this jumping might be obviated, but we think that some better form, say. qf the ratchet type, could be etn-.

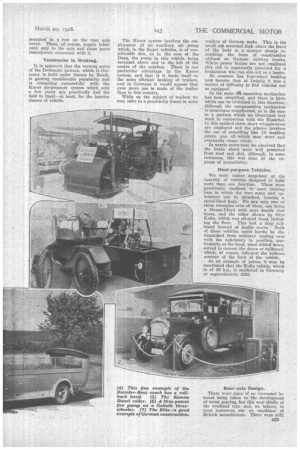

Road Tractors.

Within the main building-there were several road .tractors on view, and amengst the most conspicuous of these was the Maffei, which, in one example, was .equipped with track chains at the rear, in this Case the chains were passed around rear ;wheels equipped with ordinary twin pneumatic tyres, Whilst forward of each rear wheel was .a swivel bracket carrying a large and a small wheel shod with twin solid tyres, both these and the pneumatic tyres, of course, running on the inside of tbe track chains.

Another Maffei tractor was shown, tu eqpped with a Hellmers snow plough, .

this plough being raised and lowered as required by a hand wheel in the cab communicating with the plough via bevel gears and a worm and segment. In this case the tractor had wheels at the rear instead of tracks. One Maffei was shown with a trailer and an adhesion-indreasing device built under Chenard-Walcker patents.

In other parts of the Fair quite a number of other tractors, all of the four-wheeled pattern, were to be found. In almost every instance such tractors

were equipped with• slow-running Diesel engines, which certainly appear to give satisfactory results.

Tipping Vehicles and Gears.

We made brief reference to tipping gears in the portion of this article which appeared in our issue for last week, but it is worth while supplementing the information then given.

' One of the most successful gears appears to be the Mei'ler,' which embodies a single cylinder with a three-stage telescopic ram. Another gear resembling this, but with a four-stage ram, was shown by Armin Penner.

It will be interesting to know exactly how these tipping gears behave after considerable use, for even with singleran types it is sometimes difficult to prevent leakage of the oil, and in a pattern -where there are four potential sources of leakage the difficulty of obviating such thuble must be greatly enhanced.

A simple but effective form of gear of the purely mechanical type is that utilized by Gottfried Lindner A.G. In the pattern actually shown, and which we have already described, a single rack was employed at each side of the body. This could, be used to tip the body either to the side or to the rear, but in a more elaborate pattern, which is used on complete -vehicles, • telescoping racks are employed, and this increases the height to which the body can be raised. .

Pointers on Change-speed Gears. If we were to judge only by the exhibits at the Pair, we should be of the opinion that nothing whatever has been done towards the development of what are sometimes termed infinitely variable gears, which is a title wrongly given to gears the ratio of which.. can be altered between certain limits without abrupt steps, and sometimes auto

maticallY. However, it is possible that experiments are being carried out and have not yet reached the stage of fruition, so, perhaps, we shall see some results of these at the Berlin Show next autumn.

With one or two exceptions, gearboxes have become almost standard in their design. Even the type of box in which control of the speeds is effected through springs in such a manner that sliding of the pillions takes place only when the clutch is released, so that the operating lever can be moved before a hill and the gear changed at whatever moment is desired, appears to have far fewer adherents.

The only radical departure from standard practice was exhibited by the N.A.G. concern. In this case, however, the gearbox to which we refer was not shown in a chassis, but in conjunction with a six-cylindered power unit dis played separately. The gearing is of the epicyclic pattern, but the various clutches are brought into operation by means of electro-magnetic clutches, annular windings being carried in slots cut into the clutch faces. There are four of these windings, and they serve to give three speeds forward and reverse, whilst the current consumption is claimed to be only 35 watts. A gearbox of this type was experimented with for a longtime by Tickers; Ltd., and the main difficulty experienced was with the material employed for the clutches. Too *hard a steer causes the clutches to retain their magnetism after the current is switched off, so that the proper freeing of the clutch is prevented, whilst too soft a metal causes rapid wear upon engagement. We understand, however, that a happy mean has been struck, and we shall watch the development of this gear with some terest. We noted that, in addition to the change-speed clutches, there was a

milltiple-plate master clutch of an ordinary "type, between gearbox and engine. In most of the . smaller models the gearbox is formed as a unit with the engine, but in the larger-capacity machines the honours are more evenly distributed between wilt construction and the separate gearbox.

Vehicle Suspension A particular feature of vehicle-suspension systems on many vehicles was the Continental rubber-cushion spring shackles, which are, we. presume, built under American licence, because, this system of cushioning was first developed in the States. As the spring ends are carried entirely by the rubber, so that there is no metallic connection, adequate damping of minor vibrations should occur.

The use of rubber for such purposes is becoming more and more apparent, and it is now used to a considerable extent for engine suspension. .

In the majority of low-level chassis the spring's are, of course, underslung, and in certain cases,. Such as in the Daimler-Benz, they -are carried well below the bottom of the axle, the chassis mentioned having pillars extending downwards to carry the spring scats.

In a few vehicles the lower spring leaves are .separated from those above, so giving a measure of adjustability to

load. . .

In certain Bussing vehicles the ends of the springs are carried over cam plates, a sYsteni which was developed by the British makers of the Bristol. This shortens the "effective length of

the spring as the load increases. •

We sari' only one vehicle with anything really unusual in the suspension system. This was-the new Krupp sixwheeler, and, as we. have already referred to this, we Will not reiterate our remarks.