Prospecting for cold

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

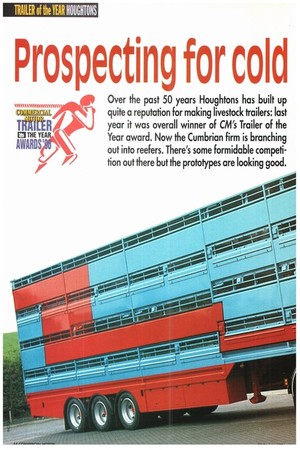

Britain s reefer building market has a new kid on the block. Any day now operators in the business of shifting foodstuffs and other temperature-sensitive products will be invited to check out the Ice Runner: the latest design from Cumbrian body and trailer manufacturer Houghtons Parkhouse Coachworks.

The reefer contrasts sharply with the HPC's pig transporter and the Professional multideck livestock container which was outright winner in last year's Commercial Motor Trailer of the Year competition.

And managing director Michael Houghton is under no illusions—he knows there's formidable competition out there. Yet, despite Gray and Adams, Schmitz, Lamberet and Chereau taking the lion's share of the market, Houghton believes there's still room for a smaller player—provided it can match and even better them in certain aspects.

He also knows that margins are going to be thin, but by making best use of Houghtons' inhouse skills he believes the Ice Runner range can be competitive. The Milnethorpe firm has been making its own chassis for many years and a fully laden livestock trailer has to be every bit as rugged as a meat railer so there's nothing to fear there.

Last month the Ice Runner prototype was tested and certified to FRC Class C levels so it meets the industry's stringent manufacturing criteria. Its temperature control and monitoring systems are also in accord with the food suppliers' high standards.

Over the past few years Houghtons has done a lot of experimental work with the Silsoe, Bedford Research Institute and has built up considerable expertise with temperature and humidity control.

Additional work on experimental vehicles involving airflows throughout a pac: stock carrier leads Houghton to belie deliver better chilled-air circulation loaded pallets or hanging meat than r For the body's roof and sidewalls I sen zinc-plated Ferroplast vertical p for its excellent reputation, but he doe out making his own later on.

The panels are 60nun thick, whic enough width for a full 26-standard pallet load with plenty of space d sides and centre for cold air to circula Instead of a rivetted assembly he's a fully bonded construction for E close-tolerance fit; it also makes fc signwriting.

Roof panels are a bonded/jointed 1 gives them adequate strength to cat rails. Fully insulated bulkhead frami jig-built and able to accept any of the makes of fridge unit without any angles to interfere with the installatic To ensure a 2.6m inner height H has opted for a 135nun insulated fl with aluminium chequer plate and welded aluminium rubbing skirts. These are bonded to the walls to give an easy-clean, hygienic appearance. Panels with woven roving laminate will be used on the inside to absorb the abrasion associated with hanging meat trailers.

There will be a full range of reefer options including multi-temperature bodywork. I-1PC has devised its own load-restraint tracking bonded into recesses for maximum width, initially for a shoring bar arrangement but there will be other choices.

The body bolts directly to a shallow-necked chassis but Houghton reckons there's sufficient bearer strength in his floor for a monocoque design.

All corners have steel angle reinforcements but externally they are neatly capped with plastic pultrusions with their lower edges cleverly slotted to accept the side panel's rubber hinge plates, stays and side marker lights. There is always danger from overhanging trees so Houghtons has recessed the lights into the front corners for protection.

Down the sides the shapely hinged side panels can be simply cosmetic or made to cover optional pallet cabinets, spare wheel carriers and the like. The rear is finished off with a neat plastic lighting surround.

With a ThermoKing SMX fridge unit and standard RO-R air-sprung ti-axle bogie the first Ice Runner tares out at 8.5 tonnes. Its early days yet for prices but Houghton says it will be competitive.

Sceptics may well wonder where a livestock trailer builder can find the necessary skills to suddenly begin producing high-quality insulated bodies: Houghton proudly points to the new 45,000fefactory which has over 1,000 different shaped foam panels. "We made them all ourselves so we have a great deal of experience in that field," he points out.

HPC also designed and produced the cutting machines, jigs and vacuum presses needed to make a variety of panels and built its own vacuum tables for making full-length floors, as well as a massive, complex assembly frame equipped with air, hydraulic and electrical power. This enables full size trailer bodies to be bonded together.

With the production infrastructure now in place Houghton knows he has to go out and find customers for his Ice Runner, but he has no intention of neglecting the livestock trailer business.

The firm is currently averaging 25 to 30 livestock trailers a month and its recent refurbishment and respray unit is also busy: it's currently working on a batch of vehicles for Eddie Stobart and has a lot of work in hand handling two-pack paint jobs, particularly on cabs.

"In general, though, business could be better," says Houghton. He cites legislation's as a major problem: "There are changes in the pipeline but the EC just cannot agree on a standard European transporter and with the BSE situation many breeders are putting their buying on hold"

However, pig hauliers are extremely active in buying vehicles and Houghton has supplied nine of the type that won CM'S Trailer of the Year competition last year. "They're high-value trailers and are in good demand," he says.

The cattle-truck business was going extremely well prior to the beef scare. Houghton believes it happened at the end of a buying cycle but everyone involved has lost money, especially the hauliers.

On the surface HPC's move into reefer manufacturing might seem to be led by the BSE scare which continues to hold Europe's attention. But the firm, founded half a century ago by Houghton's father John Houghton with £50 and a bag of carpenter's tools, it is not in the habit of knee jerk reactions. "The changes," insists Houghton, "have been on the drawing boards awhile."

In fact the new factory and the Ice Runner were planned over four years ago and with a workforce of over 50 tradesmen behind it the move is regarded as an investment in the future.

Houghton is initially targeting small fleets of 10-15 vehicles and as his sales campaign gets underway he says: "It's a long-term development, but we're backing it with a lot of commitment."

CI by Bryan Jarvis