By J. D WOO(

Page 38

Page 39

Page 40

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

e,

AFTER I had recently "seen, marked, learnt and inwardly digested " the essentials of the systems of Metropolitan Police vehicle repair and maintenance, I was asked whether I thought the organization compared well with others that I have seen. I was able to say in all sincerity that it was head and shoulders above most others, and was, indeed, a model organization for its purpose. I am persuaded that the law is quite as thorough in mechanical work as it is in its methods of crime detection!

In an earlier article I mentioned that there were over 100 garages all told. That figure, of course, includes the minor running sheds. The main garages are eight district organizations, each half-police and half-civilian, plus the big garage at Lambeth. Before entering into detail about Lambeth, I should like to go to the fountain head, as it were, and record some impressions of the main repair depot at Hendon.

Orderliness and Efficiency I went there one day with Captain R. P. Minchin, the Commissioner's transport officer at the Yard, and Mr. Williamson, from the Receiver's Engineering Department Headquarters, also at New Scotland Yard. I was introduced to the works manager, Mr. E. U. Spruce, M.B.E., A.M.I.A.E., who showed me around what was plainly his pride and joy. At once I received an impression of orderliness and efficiency. Sitting in Mr. Spruces office, we were looking out into the machine shop and the dismantling and assembly bays. Everything was clean, tidy and efficient. There were no junk-heaps, no pools of oil, no little piles of dirt and ' odd bits and' pieces. The building itself was cleanlooking; there was plenty of light green paint to ease the eyes, the lighting was good and the roof high.

"The object is to keep vehicles out of Hendon." That is a catchphrase given to me by Mr. A. A. L. Collis, the chief engineer, and I quote it as a nutshell indication of Hendon's function, Hendon is a civilian-staffed unit repair depot where power units and sub-units are made as good as new. Vehicles are repaired only when badly crashed, or in need of a body overhaul or some important modification.

The entire system is based on the principle of unit replacement, as far as humanly possible. In the present period of austerity, those replacements are seldom new, but are so completely reconditioned as to be as good as new, and life equal to that of new components is expectedfrom them. When a unit—be it an enginegearbox assembly, a sub-assembly or an auxiliary cornponent—leaves Hendon it goes into store at Lambeth, or through Lambeth to some district garage, ready to be

placed in a vehicle. In earlier days, the life of a police vehicle was about 60,000 miles; now it is nearer 300,000.

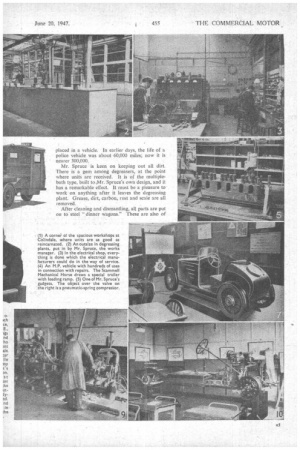

Mr. Spruce is keen on keeping out all dirt. There is a gem among degreasers, at the point where units are received. It is of the multiplebath type, built to,Mr. Spruce's own design, and it has a remarkable effect, it must be a pleasure to work on anything after it leaves the degreasing plant. Grease, dirt, carbon, rust and scale are all removed.

After cleaning and dismantling, all parts are put on to. steel "dinner wagons." These are also of the works manager's design. One wagon holds a complete unit, when dismantled. A tally device is incorporated, to show at a glance the replacement parts required. Wagons are checked by an inspector, and a list of parts needed is sent to the stores via the office. The list is in a simple numbers-code designed to save time. When wagons are made up complete, reassembly and fitting can commence at appropriate bays.

There is evidence, at all stages, of ingenuity and initiation on Mr. Spruce's part, and of the introduction of modern machine-shop and factory procedure. Mr. Collis, who was formerly with London Transport, exercises keen and experienced direction from Scotland Yard.

I was particularly impressed by the electrical shop. Here, I was told, all electrical components are given a new life. The shop can do everything that the manufacturers can do. There are two test rigs, one a Crypton and the other an Admiralty pattern. Rewinds are done by women workers. There is a special practical tester for windscreen wipers. Clever devices I noticed were neat bench jigs for distributor dismantling and reassembling, and a strip-type vice for holding armatures without injuring the windings or commutator.

Rejuvenating Carburetters In the carburetter shop I saw similar processes of rejuvenation, including the rebushing of carburetter bodies, and observed work in progress on oil-engine pumps and injectors from police motor launch engines. They showed me, as a matter of interest, one of the few sectioned oil-engine injectors in existence. It is a fine example of craftsmanship. I should really have said "injector and pump," because it is the composite unit used in the American Gray engine.

Spraying booths, coachbuilding and trimming shops, sawmill (with White combination planer and saw), tinman's and welding shops, were all of the same high order of efficiency. I saw vehicle bodies, crashed or decayed, being made good, as only craftsmen can do it. Spraying and brushing looked first-class. Trimmers were at their craft keenly, and not wasting an inch of the small stocks of tine pre-war leather still held.

A valued item of equipment is a shot-blasting plant, operated from the compressed-air line which is laid on everywhere. This has a thousand uses and is a great time-saver.

Meticulous Costing System Saving in time and money are held in great reverence. There is not a piece of machinery or equipment that does not pay its way. There has been some shrewd buying and the costing is meticulous. Travelling cranes, an outsize degreaser, the "dinner wagons," two K.B. borers, a Churchill press, a connecting rod aligner, a Bradbury brake tool, a valve-spring strength-recording machine, a pneumatic valve compressor (which has been patented), and a Churchill electric piston expander, may all be expensive initially, but they are cheap in the tong run. Additional time-savers are Mr. Spruce's own designs of engine stand and rack for holding crankshafts.

Special attention is paid to brake refacing, so as to obtain the utmost efficiency. Great care is taken to ensure that facings are tailored to fit shoes, without any air space, and that external radii are exactly right. Drums are skimmed or linered according to circumstances.

There is a special test rig for shock absorbers of the fluid type, to obtain the recommended resistances.

All engines are tested by dynamometer in a test house containing three brakes. They go on test with their own auxiliaries and are thus under working conditions. . I wish I could tell at length the story of Hendon's war contracts. It must suffice to say that wonders were worked for Combined Operations Command, the Royal Navy and other Services, to the tune of 750,000 h.p. Many seemingly impossible tasks were achieved in record time. Clever repairs and improvizations saved the day on many occasions, and senior military and naval officers were often given valuable technical advice.

Mr. Spruce was presented with the M.B.E. for his work. He is a modest man with extensive mechanical and drawing office experience, and is at present compiling a technical instructional manual in his spare time.

The total staff at Hendon is 155, including chargehands and foremen. There are 41 fitters, 19 electrical staff, 11 painters, 11 tinsmiths, 7 coachbuilders, 7 turners, 6 trimmers, 5 dynamometer hands, 3 welders, 3 police lantern repairers,1 draughtsman and several clerks.

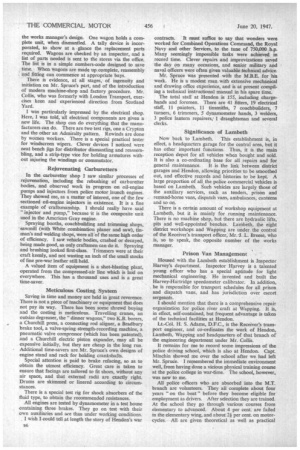

Significance of Lambeth Now back to Lambeth. This establishment is, in effect, a headquarters garage for the central area, but it has other important functions. Thus, it is the main reception depot for all vehicles when bought and sold. It is also a co-ordinating base for all repairs and for general maintenance. It is the link between district garages and Hendon, allowing priorities to be smoothed out, and effective records and histories to be kept. A large proportion of all the police commercial vehicles is based on Lambeth. Such vehicles are largely those of the auxiliary services, such as tenders, prison and remand-home vans, dispatch vans, ambulances, canteens and so on.

There is a certain amount of workshop equipment at Lambeth, but it is mainly for running maintenance. There is no machine shop, but there are hydraulic lifts, pits and well-appointed benches. Lambeth, the eight district workshops and Wapping are under the control of the Receiver's transport officer, Mr. J. L. Breese, who is, so to speak, the opposite number of the works manager.

Prison Van Management Housed with the Lambeth establishment is Inspector Harvey's department. Inspector Harvey is a talented young officer who has a special aptitude for light mechanical engineering. He invented and built the Harvey-Hartridge speedometer calibrator. In addition, he is responsible for transport schedules for all prison and dispatch vans, and has jurisdiction over escort sergeants.

I should mention that there is a comprehensive repair organization for police river craft at Wapping. It is, in effect, self-contained, but frequent advantage is taken of the technical facilities at Hendon.

Lt.-Col. 11_ S. Adams, D.F.C., is the Receiver's transport engineer, and co-ordinates the work of Hendon, Lambeth, Wapping and headquarters of that branch of the engineering department under Mr. Collis.

It remains for me to record some impressions of the police driving school, which is also at Hendon. Capt. Minchin showed Erie over the school after we had left Mr. Spruce. I remembered the immediate environment well, from having done a vicious physical training course at the police college in war-time. The school, however, was new to me.

All police officers who are absorbed into the M.T. branch are volunteers. They all complete about four years "on the beat" before they become eligible for employment as drivers. After selection they are trained. At the school they go through various courses from elementary to advanced. About 4 per cent. are failed in the elementary wing, and about 21per cent. on motorcycles. All are given theoretical as well as practical instruction. Police drivers are, not expected to carry out running repairs, but they must have a fair knowledge of technicalities.

There is no, special instruction for commercial-vehicle driving. If a driver wishes to transfer to commercial vehicles, he makes application after having been trained on cars. Most-coveted job is that of driving a staff car.

We looked at the unique museum in the school. Here are to be seen all the horrors of wrong or non-existent maintenance—a loosely mounted wheel which tore itself off; a half-shaft wrenched into a quarter-shaft by running with worn spines; an oil filter choked into the semblance of a treacle pudding; the over-tightened union nut; the paper-thin brake facing; the burned-out coil.

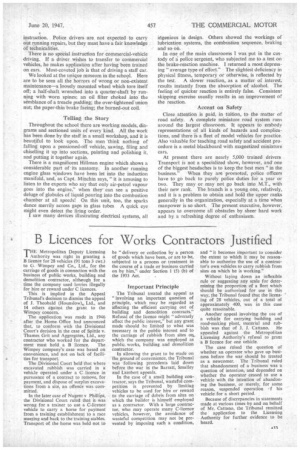

• Telling the Story Throughout the school there are working models, diagrams and sectioned units of every kind. All the work has been done by the staff in a small workshop, and it is beautiful to look upon. The men Think nothing of falling upon a pensioned-off vehicle, sawing, filing and chiselling it up into sections, painting and polishing it, and putting it together again.

There is a magnificent Hillman engine which shows a considerable part of• its anatomy. In another running engine glass windows have been let into the induction manifold, and, as Capt. Minehin says, "it is amusing to listen to the experts who say that only air-petrol vapour goes into the engine," when they can see a positive deluge of globules of liquid pouring into the combustion chamber at all speeds! On this unit, too, the sparks dance merrily across gaps in glass tubes A quick eye might even detect the firing -order. 1 saw many devices illustrating electrical systems, all

ingenious in design. Others showed the workings of lubrication systems, the combustion sequence, braking and so-on.

In one of the main classrooms I was put in the custody of apolice sergeant, who subjected me to a test on the brake-reaction machine. I returned a most depressing "average type of effort." The slightest deficiency in physical fitness, temporary or otherwise, is reflected by the test. A slower reaction, as a matter of interest, results instantly from the absorption of alcohol. The.. feeling of quicker reaction is entirely false. Consistent skipping exercise usually results in an improvement of the reaction.

Accent on Safety Close attention is paid, in tuition, to the matter of road safety. A complete miniature road system runs around the largest classroom. It appears to embody representations of all kinds of hazards and complications, and there is a fleet of model vehicles for practice. Also valuable for teaching road safety and accident procedure is a metal blackboard with magnetized miniature cars.

At present there are nearly 5,000 trained drivers Transport is not a specialized show, however, and one of the biggest headaches is to keep the best men "in the business." When they are promoted, police officers have to go back to purely police duties for a year or two. They may or may not go back into MT., with their new rank. The branch is a young one, relatively, and it is a problem to obtain and hold the upper ranks generally in the organization, especially at a time when manpower is so short. The present executive, however, appears to overcome all obstacles by sheer hard work and by a refreshing degree of enthusiasm.