TANK ATTACK

Page 108

Page 109

Page 110

If you've noticed an error in this article please click here to report it so we can fix it.

Judging by exhibits at this year's Tankcon show, continental manufacturers are queueing up to grab a share of the UK market— but there is plenty of homebrewed innovation to give them a run for their money.

• Tanker operators in the market for innovation, weight saving and vehicle longevity would have found much of interest at this year's International Tanker Convention and Exhibition which was staged at Charnock Richard, Lancashire by the Road Haulage Association.

Regular exhibitors from Belgium, France, Holland and West Germany were joined by newcomer Feldbinder of Hamburg, with visitors from around the world strengthening the cosmopolitan flavour.

Despite the 10-year wait for 40-tonnes, many operators seem prepared to take a longterm view by investing in tankers built almost entirely of ever-more

expensive stainless steel to carry a wide range of hazardous chemicals. Nonhazardous-carrying companies are pulling out all the stops to minimise unladen weight and improve productivity.

The lightweight 38/40-tonne GCW tanker semi built by Melton Tankers for ITS Rentals of Walsall can perform a dual role, carrying 27,300 litres of milk or even edible oils thanks to a thicker divisional plate.

The tank and subframe are both built from stainless steel, but to help keep the tare weight down to 5,720kg Melton has used plastic brackets for the walkways which, like the sideguards, are made of aluminium.

FRENCH OPERATORS

SAF's AR414 and REM 9041 lightweight air suspension and axles are also part of the package. Melton has built 15 tankers of this design for ITS and TIP for their rental businesses: it is now talking to French operators.

Among Universal Bulk-Handling's three exhibits was a 20,000-litre singlecompartment carbon-steel tanker, rubber lined for carrying hydrochloric acid. It was shown with a pair of 30,000-litre stainless-steel tankers, built to carry a tonne payload and with ADR/IM04 classification, Over 100 vehicles with similar specifications are in service with Relianc and Cleveland Tankers.

The Burscough-based company, formerly part of the Laird group, is now subsidiary of Yorkshire Marine Containers, which is in turn part of Sea Containers. Since the change of ownership late last year, UB-H has received investments of around £2.0 million and its tanker production is bouyant, particularly for third-party customers such as Gilbraith, Reliance Tankers and TankFreight.

UB-H expects to build over 300 ISO tank containers this year, along with about 100 of its refrigerated tank 'tainer! for its parent group's expanding fleet. It latest move is into LPG tankers, two of which have been built for Shell's Unigas fleet.

International bulk chemicals carrier Hoyers (UK) demonstrated its 24-hour emergency support service, which includes a pair of fully-equipped vehicle! to carry product experts, HGV drivers and phone/fax links from the company's Huddersfield base to an incident. This service is designed primarily as an added benefit for Hoyer's customers, but as the company is part of the Kirk lees Hazardous Chemicals committee, it will also provide assistance on a regional and national level.

The group's UK arm has further developed its GRP back-of-cab rucksackshaped hose carrier/equipment cabinet, and is supplying it to its parent for assessment. Other developments include improved tank cleaning plants and a growing use of swap body tanks.

Dry powder tanks are the forte of Umberto Piacenza Rimorchi, York Group's Cremona-based Italian subsidiary, which claims to be market leader at home in that sector.

York debuted an aluminium 34m3 tipping powder tanker built to UK specification.

STEEL CHASSIS

[t uses a steel chassis with York Tecair mounted tip gear. Twin mechanical rear ttabilisers are fitted as standard along with four 410mm top manholes, a 650mm .ail-end discharge hatch, safety rail, :atwalk and rear ladder.

The 11.15m-long, 3.62m-high semi weighs in at 6,850 kg. This includes a full 3i1 tank and spare wheel. It will retail at around £34,000.

There was an innovative flavour to the Metalair tankers on show, including Singleton Birch's 55,500-litre powder tanker with its unusual aluminium chassis rails which eliminate the need to weld to the chassis„ A 55.4m tipping tanker used by Tankcon exhibitor Harris Powderline to carry bulk plastic granules and the like to the fleet's bulk food carriers uses pipework that can easily be stripped out for decontamination. The plumbing system was designed by the vehicle's owner, the bulk cargo division of Harris Road Services.

Metalair's 32.6m3 non-tipping Urban Artie tanker is intended for delivering flour to sites with restricted access. To help minimise noise when discharging, its luxiliary engine is contained within an [mutated cabinet and its air release beneath the tank has also been enclosed.

Another busy tanker builder is NE! Thompson Tankers, whose parent group, SIEI Northern Industries, is rumoured to ne about to merge with Rolls-Royce.

Its exhibits included a vintage Thompson/Albion paraffin tanker and its modern equivalent a 4,500-litre aluminium-tank airport refueller for light aircraft.

Based on a pet-reg Mercedes-Benz 809 7.5-tonne chassis with automatic ransmission, it delivers metered fuel over the wing, but is itself filled via a oottom-loading system with vapour recovery. The tanker is one of several in service at airports around the country, and is a design that may well be part of a recently won large contract for military airfield refuellers.

A 55m3 high-pressure tipping powder tanker with an aluminium tank and chassis is one of seven similar high-spec semi-trailers built by Belgium manufacturer LAG for Sayers Transport Services of Newbury.

It tips using a Bosch 24-volt electrohydraulic pump, mounted on the side of the chassis trailer and fed by the tractor's batteries. The tipping ram is enclosed within the front of the tank.

EAST GERMANY

Brie-based LLscA Geusens is currently building around 2,000 tankers of all types which it sells throughout Europe, particularly East Germany which is its strongest market. It is said to have around 60 tankers in build at any one time.

Most non-UK tankers favour the Bosch tipper system for its lightness and ease of usc, but it does add £3,000 to the purchase price. Ready for the road, the Sayers vehicle weighs in at 7,700kg and retails at about £45,000.

Another LAG (UK) customer is Durhams, which runs 10 such tankers and specifies the option of hydraulic support legs which extend before the tank raises.

Dijon-based Magyar is building swap tank/tri-axled semi-trailer intermodal systems using 6.1 or 9.1m ISO tanks which are RTMD/ADR/RID/IMO approved. These are intended for the road/rail distribution sector, particularly on the Continent, where an extra four tonnes may be carried within a limited distance of the transport depot or railhead.

The unit shown at Tankcon has an unladen weight of five tonnes on three RO-R air-suspended axles, each rated at 10 tonnes and fitted with 265/70R 19.5in tyres. Over 200 of Magyar intermodals have been sold to date, mainly to leasing companies.

An 11.76m insulated, stainless-steel food-grade tanker in United Biscuits' McVitie's livery was also displayed. Its double-cone, three compartment structure has cladding material up to 200mm thick in places. With the independent Webasto water heater, it is claimed to be one of the most costeffective chocolate-carrying tankers around — thanks to steam heating it is claimed that less of the product is lost during discharge. All but 10kg is drained, saving up to 115kg that would otherwise be lost during cleaning.

Newcomer to the UK market, Feldbinder of Winsen, near Hamburg has been producing tankers for 14 years and is producing 300 units a year.

It claims a 34% West German market share and is confident that its low tare weight will earn it a toehold in the British market.

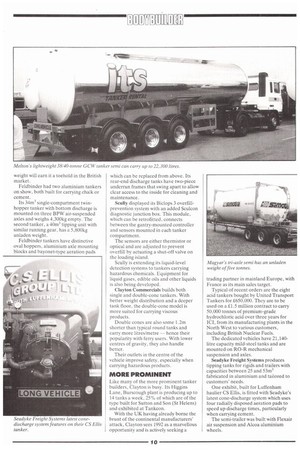

Feldbinder had two aluminium tankers on show, both built for carrying chalk or cement.

Its 34m3 single-compartment twinhopper tanker with bottom discharge is mounted on three BPW air-suspended axles and weighs 4,300kg empty. The second tanker, a 40m3 tipping unit with similar running gear, has a 5,800kg unladen weight.

Feldbinder tankers have distinctive oval hoppers, aluminium axle mounting blocks and bayonet-type aeration pads which can be replaced from above. Its rear-end discharge tanks have two-piece underrun frames that swing apart to allow clear access to the inside for cleaning and maintenance.

Scully displayed its Biclops 3 overfillprevention system with an added Sculcon diagnostic junction box. This module, which can be retrofitted, connects between the gantry-mounted controller and sensors mounted in each tanker compartment.

The sensors are either thermistor or optical and are adjusted to prevent overfill by actuating a shut-off valve on the loading island.

Scully is extending its liquid-level detection systems to tankers carrying hazardous chemicals. Equipment for liquid gases, edible oils and other liquids is also being developed.

Clayton Commercials builds both single and double-cone tankers. With better weight distribution and a deeper tank floor, the double-cone model is more suited for carrying viscous products.

Double cones are also some 1.2m shorter than typical round tanks and carry more litres/metre hence their popularity with ferry users. With lower centres of gravity, they also handle better.

Their outlets in the centre of the vehicle improve safety, especially when carrying hazardous products.

MORE PROMINENT

Like many of the more prominent tanker builders, Clayton is busy. Its Higgins Lane, Burscough plant is producing up to 14 tanks a week, 25% of which are of the type built for Sutton and Son (St Helens) and exhibited at Tankcon.

With the UK having already borne the brunt of the continental manufacturers' attack, Clayton sees 1992 as a marvellous opportunity and is actively seeking a trading partner in mainland Europe, with France as its main sales target.

Typical of recent orders are the eight acid tankers bought by United Transport Tankers for £650,000. They are to be used on a £1.5 million contract to carry 50,000 tonnes of premium-grade hydrochloric acid over three years for ICI, from its manufacturing plants in the North West to various customers, including British Nuclear Fuels.

The dedicated vehicles have 21,140litre capacity mild-steel tanks and are mounted on RO-R mechanical suspension and axles.

Seadyke Freight Systems produces tipping tanks for rigids and trailers with capacities between 25 and 53m3 fabricated in aluminium and tailored to customers' needs.

One exhibit, built for Luffenham haulier CS Ellis, is fitted with Seadyke's latest cone-discharge system which uses four radially disposed aeration pads to speed up discharge times, particularly when carrying cement.

The semi-trailer was built with Flexair air suspension and Alcoa aluminium wheels.