( From the Drawing Boer

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

by Graham Montgomer E

IN THE LAST feature in this series I described some of the research work being done on noise. This time I am looking at another of the "'emission" problems of the diesel engine — black smoke.

I have been talking to Leslie Hartridge Ltd at Buckingham, who are very much involved in the proposed "lug down" test for assessing smoke emission.

For some time now the DTp has been discussing with industry how to find a method of measuring the smoke emitted under operating conditions. All the parties agree that it is necessary actually to meter the smoke.

Subjective assessment using, say, white boards as a background was all very well, but lacked "repeatability." Once that decision was made, it was obviously necessary to decide upon the technique, and various methods were investigated. These included running the vehicle on rollers at a steady speed and a controlled acceleration against inertia on a dynamometer.

The first was rejected because it is quite feasible for an engine to have a ''devious'' smoke curve, so the particular speed was of paramount importance. This meant that there would be a lot of luck involved as to whether the vehicle passed or failed. The dynamometer test was rejected as not being feasible for a high throughput of vehicles.

Hartridge then put forward the idea of a controlled deceleration lug down technique, and demonstrated it at the Bicester vehicle testing station, looking at the smoke subjectively and measuring it by the lug down technique. The results were successful, with good correlation between the metered readings and the subjective assessment.

The vehicle to be tested is put on the rollers and run up to governed engine speed in the gear which will give between 30 and 40 mph.

With this gear engaged and the engine running at the governed speed, the operator then adjusts the speedmeter — which is hung up outside the ilk cab in the operator's line of sight

— by means of a remote control handset so that the dial reads 100 per cent.

The examiner then carries out a practice lug down without taking any measurements. This is done merely so he can familiarise himself with the characteristics of the vehicle on things like pedal travel, for example.

The actual lug down procedure is as follows: with the vehicle in the chosen gear and at 100 per cent of governed speed, the examiner gradually applies the service brake with his left foot while keeping the accelerator fully depressed.

He continues braking until the engine speed has been brought down to 40 per cent in as smooth a manner as possible in 10 seconds for naturally aspirated, and 15 seconds for

turbocharged engines. Immediately 40 per cent has been reached. both the brake and the accelerator are released and the engine (still in gear) is allowed to run at 40 per cent speed for 30 seconds prior to performing the first recorded lug down.

The examiner now carries out three lug down tests with the recorder in operation. This can be switched on via a control on the handset. After each test the operator allows 30 seconds running at 40 per cent speed before starting the next. If any of the lug downs exceed 15 seconds, a flashing light on the speedmeter warns the operator that he should run at 40 per cent for a further 30 seconds in order to facilitate brake cooling.

The length of the vehicle's exhaust pipe is not of particular importance although Hartridge try to keep the length of the sampling pipe down. As far as diameter is concerned, the sample pipe diameter should have a certain ratio with the vehicle pipe.

The pen recorder which provides a permanent record of the vehicle's performance has a number of safety features built in. When the handset switch is set at -record,the pen is lowered automatically when the speedmeter reaches 100 per cent. When the speed falls below 40 per cent, the pen is lifted off the chart and cannot be lowered again until 100 per cent is reached again. This results in clear recordings over the relevant parts of the cycle.

A deceleration rate detection function is also incorporated in the pen recorder. If the deceleration is too rapid, the pen is again lifted off automatically. The deceleration rate is pre-set at 15 per cent per second for naturally aspirated engines, and at 10 per cent per second for. turbocharged: As I mentioned earlier, the lug down test is meant to be carried out over a specified time period, If this time is exceeded, the pen is again lifted off.

So much for the actual measurement of the-smoke density. Now how do we go about checking whether it comes within the recommended guidelines?

The limiting value for smoke opacity is related to the engine gas flow. Thus it is a function of both engine speed and cubic capacity. For a four stroke engine the gas flow (Q) in litres/ sec is evaluated thus: Swept Volume (V)X Engine

Speed (N)

120 For a two stroke engine the denominator is 60.

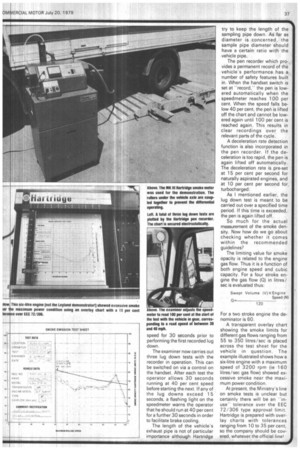

A transparent overlay chart showing the smoke limits for different gas flows ranging from 55 to 350 litres/sec is placed across the test sheet for the vehicle in question. The example illustrated shows how a six-litre engine with a maximum speed of 3200 rpm lie 160 litres/sec gas flow) showed excessive smoke near the maximum power condition.

At present, the Ministry's line on smoke tests is unclear but certainly there will be an "inusetolerance over the EEC 72/306 type approval limit. Hartridge is prepared with overlay charts with tolerances ranging from 10 to 35 per cent, so the company should be covered,. whatever the official line!