THE POSSIBILITIES )F SUPERCHARGING

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

on comme vehicles

AT the present time experiments with supercharging on an important scale are being made by several builders of commercial vehicles. There can be but little doubt that these are prompted by the desire to reduce the size and weight of the power unit required for a specific purpose. These experiments, therefore, follow a trend which has been steadily pursued since the advent of the internal-combustion engine.

The weight per brake-horse-power of commercialvehicle engines of conventional design ranges from 10 lb. to 15 lb., according to their size and type. For various reasons, supercharging is likely to find its first application to large engines developing 100 b.h.p. or more. In such cases, using quite moderate pressures, it might well make possible a 35 per cent. saving in weight, coupled with a reduction in . overall linear dimensions of about 12 per cent.

Advantages of a Compact Engine.

The advantages of weight reduction, from the viewpoint of performance, running costs and taxation, require no stressing. Overall dimensions are becoming almost equally important, owing to the tendency to utilize as large a proportion of the chassis for load-carrying purposes as may be made possible by adopting forward control or by shifting the engine to a location amidships.

Supercharging has special claims for consideration as a means for reducing the weight and size of engines in comparison with alternative methods hitherto exploited. At the outset, it is important to realize that road performance depends not only upon the maximum power output of the engine, but also upon the torque which it will develop. In popular language, the latter characteristic may be described as the pulling capabilities of the power unit.

By increasing the bore and stroke, both torque and power can be augmented, but this simple method naturally increases the weight and size of the engine in like proportion.

Next, there is the expedient of raising the compression pressure, which is limited (in petrol engines) by the tendency of the fuel to detonate and, in compression-ignition engines, by the fact that the maximum explosion pressure is correspondingly increased. An engine with a high compression pressure is also usually at a disadvantage in respect of smooth running.

OIL PUMP

Consideration of Torque and Power.

An alternative plan, and one which has been steadily followed for many years, is to secure an increase in power output by raising the useful revolution speed of the engine. This involves close attention to the design of the valves, ports and valve-operating gear. In this way, the maximum power output can be raised, but, as a rule, changes which increase the power at high speeds do nothing to improve the torque at low speeds, or may even have an adverse effect in this respect.

In its early applications to racing cars, the superzi32 charger was mainly employed to sustain the power output up to much higher revolution speeds than are prac.ticable with atmospheric induction. The more modern conception of supercharging, however, is to secure art increase of torque and power throughout the speed range. For example, with quite a moderate induction pressure, ranging from 6 lb. per sq. in. up to a maximum of 10 lb. per sq. in., it is found possible to increase the power output of a given engine by about 25 per cent. at 1,000 r.p.m., rising to 50 per cent. at 2,000 r.p.m. and over.

Such results have been made possible by improving the low-speed pumping efficiency of the supercharger and by increasing its capacity. The pressure developed at high speeds can be limited, if desired, by means of a regulating valve.

Rate of Wear and Reliability.

When any method for increasing the torque and power output is under consideration, its effect upon the loading, rate of wear and general reliability of the power unit must receive careful attention. In these respects, it can justly be claimed that supercharging presents certain special advantages over alternative methods.

The main and big-end bearings, for example, are loaded both by the gas pressure above the pistons and by the inertia forces created by the reciprocating parts at high speeds. A moderate degree of supercharging, suitably controlled, will not appreciably increase the bearing loads under either of these conditions. In comparison,.

ORM the methods of raising the revolution speed FROM or the compression pressure both show to a

disadvantage.

On the other hand, supercharging increases the quantity of heat flowing to the piston crowns, piston rings, exhaust valves and sparking plugs, so that the design of these parts requires special consideration. There seems but little doubt, however, that, with modern valve materials, separately inserted valve seatings, wet cylinder liners, alloy pistons, etc., the engine designer is quite able to cope with the heat problems which supercharging presents.

The next point to consider is the design and application of the supercharger itself. As applied to the great majority of racing cars and aero engines, the supercharger is in use continuously, being either directly coupled to the crankshaft, or driven through gearing. It is usually designed to draw a petrol-air mixture from the carburetter and to deliver it under pressure to the inlet manifold.

An incidental advantage is that the churning effect of the supercharger helps to break up and vaporize the mixture, so assisting equable distribution, ready starting and general flexibility.

The Clutch-controlled Supercharger.

There is, however, another method of applying the supercharger, in which it is placed on the air-intake side of the carburetter and is driven through a small friction clutch. An outstanding example is found in the Mercedes-Benz private-car chassis, which is so arranged that, under normal conditions, the accelerator merely controls the throttle and the supercharger is inoperative. Should the driver require additional power for acceleration or

hill-climbing, he depresses the accelerator beyond its nurmal range of travel (against a stiff spring), so engaging the clutch and bringing the supercharger into action.

This plan might well prove of value for motor coaches and other vehicles in which the power required for normal cruising is a great deal lower than the peak power needed for acceleration and hill-climbing.

The clutch-controlled type of supercharger could be fitted to a compression-ignition engine far more readily than to a petrol engine. In the latter case, the fact that it blows the air into the carburetter involves the use of balance pipes to exert an equal pressure upon the fuel tank and float chamber, so that the change-over from atmospheric induction to "forcible feeding" becomes somewhat complicated.

In a compression-ignition engine, air is supplied to the cylinders instead of a fuel-air mixture, thus simplifying the problem.

To fit a supercharger adds to the complexity and cost of a power u4it, but these factors alone have never yet proved sufficient to prevent the introduction of any component which can show real and practical advantages. Nevertheless, it is important that the supercharger should be at least as reliable and long-lived as the other parts of an engine.

During the past few years a great improvement has been effected in supercharger design. As a result, the modern supercharger is both quiet and efficient.

At one time it was necessary to mix a proportion of oil with the petrol to lubricate the supercharger parts, but this disadvantage has been overcome by developing small but efficient pumps specially designed to lubricate the supercharger with minute quantities of oil derived from the main engine sump.

Disregarding the high-speed centrifugal blower of the type popular in America for racing cars, there are at present two types of supercharger suitable for application to commercialvehicle engines. Of these, the B34

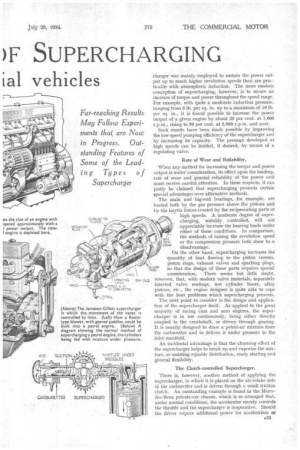

Roots-type blower is largely favoured by those private. car makers who build their own superchargers, and is produced by certain specialists, notably David Brown I and Sons, Ltd., of Huddersfield.

In the Rocs blower two " figure-of-eight " paddles are employed, running on parallel shafts coupled by gearing. A small clearance can be continuously maintained between the paddles and between each paddle and the casing,so that with proper care in manufacture this type of blower is very reliable and presents no difficulty in respect of lubrication. The accuracy with which the gears are cut is of great importance to the efficiency of the compressor.

The alternative vane-type blower is made in many forms, such as the Cozette, Powerplus, Zoller, JamesonGillett and Centric ; the principle is to employ a drum (carrying radial vanes) which is mounted eccentrically in a circular casing. Various methods are employed to control the movement of the vanes. Whilst more diffi cult to lubricate, the vane-tyfe blower is usually more compact and less costly than the Roots device, and also it requires less power to drive it.

In conclusion, it is worth remarking that the application of supercharging may well remove the disability of increased weight, under which the compression-ignition engine suffers at present in comparison with the petrol engine. Furthermore, forced induction may accelerate the development of a compression-ignition engine operating on the two-stroke cycle by making it possible thoroughly to scavenge the cylinders with air under pressure. Large twostroke units of the supercharged type have proved highly successful for marine work.