Turning a Hole into a Window

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

VDIVIDUALITY in body design has

often resolved itself into a question of unusual window design. This introduces an intrinsic constructional complexity and is often expensive.

To provide an inexpensive window, Beckett, Laycock and Watkinson, Ltd., Acton Lane. London, N.W. 0„ has dereloped a method of glazing which enables the operator to replace glasses in an extremely short time.

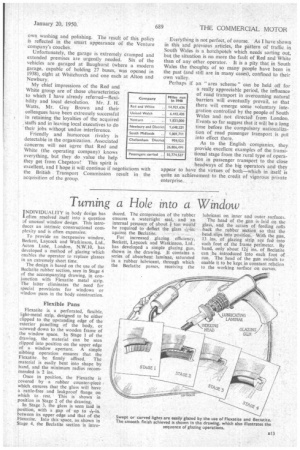

The design is based on the use of the Beclatite rubber section, seen in Stage 4 of the accompanying drawing, in conjunction with Flexatite metal strip. The latter eliminates the need for special provisions for windows or window pans in the body construction.

Flexible Pans Flexatite is a perforated, flexible, light-metal strip, designed to be either clipped to the upstanding edge of the exterior panelling of the body, or screwed down to the wooden frame of the window space. In Stage 1 of the drawing, the material can be seen clipped into position on the upper edge of a window aperture. A simple nibbing operation ensures that the Flexatite be firmly affixed. The material is easily bent into shape by hand, and the minimum radius recommended is 2 ins.

Once in position. the Flexatite is covered by a rubber counter-piece which ensures that the glass will have a rattle-free and leakproof flange on which to rest. This is shown in position in Stage 2 of the drawing.

In Stage 3, the glass is seen laid in position, with a gap of up to h-in. between its upper edge and that of the Flexatite. Into this space, as shown in SLage 4, the Beclatite section is intro

duced. The compression of the rubber ensures a ,watertight seal, and •an internal pressure of about ton would be required to deflect the glass Y6-in. against the Beclatite.

For increased glazing efficiency, Beckett, Laycock and Watkinson, Ltd., has developed a simple glazing gun, shown in the drawing. It contains a series of absorbent laminae, saturated in a rubber lubricant, through which the Beclatite passes, receiving the

lubricant on inner and outer surfaces.

The head of the gun is laid on the glass,. and the action of feeding rolls back the rubber section so that the bead slips itito'position. With the gun, 13 ins, of glazing strip are fed into each foot of the frame perimeter. By hand, only about 12-i ins. of Beclatite can be introduced into each foot of run. The head of the gun swivels to enable it to be kept in constant relation to the working surface on curves.