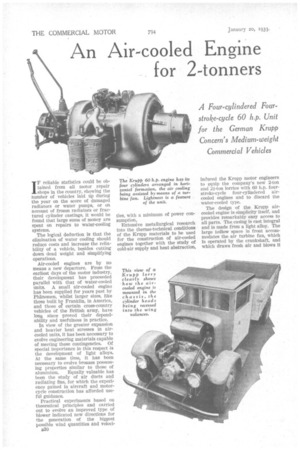

An Air-cooled Engine for 2-tonners

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

IF reliable statistics could be obtained from all motor repair shops in the country, showing the number of vehicles laid up during the year on the score of damaged radiators or water pumps, or on account of frozen radiators or fractured cylinder castings, it would be found that large sums of money are spent on repairs to water-cooling systems.

The logical deduction is that the elimination of water cooling should reduce costs and increase the reliability of a vehicle, besides cutting down dead weight and simplifying operations.

Air-cooled engines are by no means a new departure. From the earliest days of the motor industry, their development has proceeded parallel with that of water-cooled units. A small air-cooled engine has been supplied for years past by Phanomen, whilst larger sizes, like those built by Franklin, in America, and those of certain cross-country vehicles of the British army, have long since proved their dependability and usefulness in practice.

In view of the greater expansion and heavier heat stresses in aircooled units, it has been necessary to evolve engineering materials capable of meeting these contingencies. Of special importance in this respect is the development of light alloys. At the same time, it has been necessary to evolve bronzes possessing properties similar to those of aluminium. Equally valuable has been the study of air ducts and radiating fins, for which the experience gained in aircraft and motorcycle construction has afforded useful guidance.

Practical experiments based on theoretical principles and carried out to evolve an improved type of blower indicated new directions for the generation of the biggest possible wind quantities and veloci n30 ties, with a minimum of power consumption, Extensive metallurgical research into the thermo-technical conditions of the Krupp materials to be used for the construction of air-cooled engines together with the study of cold-air supply and heat abstraction, induced the Krupp motor engineers to equip the company's new 2-ton and 2i-ton lorries with 60 h.p. fourstroke-cycle four-cylindered aircooled engines and to discard the water-cooled type.

The design of the Krupp aircooled engine is simplicity itself, and provides remarkably easy access to all parts. The casing is cast integral and is made frOm a light alloy. The large hollow space in front accommodates the air turbine fan, which Is operated by the crankshaft, and which draws fresh air and blows it through the spacious cylinder jacket, sweeping every cylinder with its cold air.

The cylinders are arranged in flat-opposed formation. This rather striking feature is explained by the desire to obtain as low a centre of gravity for the engine as possible, and by the fact that the arrangement of the cylinder heads projecting in pairs beyond the longitudinal members of the chassis, affords a good exploitation a the cooling air, assisted by the wind.

As the air turbine is mounted on the crankshaft, it supplies the cylinders with a quantity of cooling air always proportionate to the speed of the engine, and produces a uniform cooling effect under all operating conditions. Additional to the special design of the combustion chamber, this method of cooling is chiefly responsible, we understand, for the exceptionally high output of the engine relative to the piston displacement, whilst reducing fuel consumption to 20-30 per cent. below that of water-cooled engines of identical performances.

The strong crankshaft, which is protected against vibrations by balance weights and carries a Siemens 400-watt lighting outfit in • front of the turbine, is as readily accessible as are the camshaft and the connecting rods after the removal of the top or bottom cover 'of the crankcase. A horizontal carburetter and an air filter are mounted on the top cover.

Notwithstanding its light weight, the chassis is very stable. The strongly built frame has a kick-up at the front and carries a four-speed gearbox. Power is transmitted by means of a cardan shaft, and the rear-axle bevel drive, with differential, is accommodated in the solid rear axle, which is made of a pressed special alloy.

The lorry has a turning radius of only 5.50 metres, and this, in conjunction with its remarkable performance, its efficient springing and its good. starting and pulling properties, produces excellent results on the road. Safety is enhanced by an oil-pressure foot brake acting on all four wheels add a hand brake acting on the transmission. .

This type of chassis is used also for buses carrying up to 24 passengers. A point of importance is that vehicles equipped with these aircooled engines have been in regular service for the past 11 years and have thus passed the experimental stage.