MAKING BEST USE OF THE FORD.

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, Which Will Appeal to the Owner, Driver and Repairer,

IN THIS series of hints concerning the Ford light chassis and ton truck wherever they are employed for commercial purposes, we endeavour to deal with the subject from every view-point, so that the advice given will appeal to the owner, driver, maintenance engineer or mechanic.

We shall welcome for inclusion among the hints those which have proved of value to individual users, and will make suitable remuneration for any such information which we publish. What we desire are the results of actual practice. Readers are recommended to obtain the original "Book of the Ford," which constitutes a complete manual dealing with the Ford car, the van and the truck. 2s. 9d. post free from the offices of this journal.

276_—Assembling the Triple Gears.

After the gears on the Ford have been dismantled and the task of reassembling becomes necessary, difficulty is often experienced in the fitting of the triple gears, but the following hint has been followed with success on many occasions. When the gear drums are to be built up as shown in ouf illustration, on the top wheel there are 27 teeth. Mark one tooth and fit one of the planet wheels properly into mesh, then count nine teeth and fit the second wheel, count a further nine teeth and fit the third wheel, then obtain a piece of string and tie this round the gears to keep them in mesh, after which they may be placed on the gearshaft and manceuvred into position on the dowels, when the string may be removed.

277.—Curing Belt-slip and Other Fan Troubles.

Inefficiency of the fan and its drive lead to overheating. The belts should be made of flexible leather, well stretched before being fitted, and if they slip they should be treated with a composition consisting of 1 lb. of tallow, # lb. of resin and some brown paper cut very small—in fact, almost powdered. Warm this mixture until it runs and apply thinly to each belt, not using an excessive quantity, or the belt will grip the pulley too fiercely. If a pulley has become so polished that it promotes slipping, a piece of calico may be glued round it—of course, a flexible glue must be employed. In the older types the fans may be too small and not up to their work. The blades may then be ex

tended by the use of suitable pieces of stout tin or thin steel sheet riveted to them, care being taken that the fan is not put out of balance.

Another method of improving the notion of the fan is to employ a fan tunnel, consisting of a sheet of thin metal suitably bent and bolted to the inner side of the radiator. It must fit fairly closely to the ends of the fan blades.

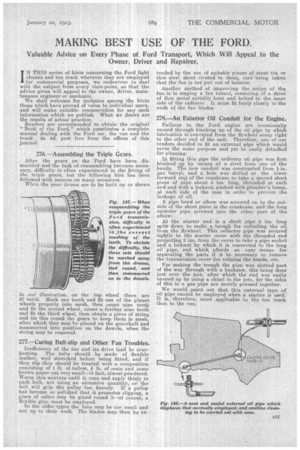

278.—An Exterior Oil Conduit for the Engine.

Failures in the Ford engine are occasionally caused through blocking up of the oil pipe by which lubrication is conveyed from the flywheel sump right to the other end of the unit. Therefore, one of our readers decided to fit an external pipe which would serve the same purpose and yet be easily detached for cleaning.

In fitting this pipe the ordinary oil pipe was first blecked up by means of a rivet from one of the bands. The new conduit was constructed from i-in. gas barrel, and a hole was drilled at the lower forward end of the crankcase to take a second short piece of pipe about 3 ins, long, threaded at each end and with a locknut, packed with plumber's hemp, at each side of the case in order to prevent the leakage of oil.

A pipe bend or elbow was screwed on to the outside of the short piece in the crankcase, and the long exterior pipe screwed into the other part of the elbow.

At the starter end is a short pipe 5 ins, long spliit down to make a trough for collecting the oil from the flywheel. This collector pipe was secured tightly to the starter cover with the threaded end projecting 2 ins, from the cover to take a pipe socket and a locknut by which it is connected to the long oil pipe, and which affords an easy means for separating the parts if it be necessary to remove the transmission cover for relining the bands, etc.

For making the trough the pipe was slotted part of the way through with a hacksaw, this being done just over the join, after which the end was easily opened up by using a chisel in the join, for the sides of this in a gas pipe are merely pressed together.

We would point out that this external type of oil pipe cannot be employed when a starter is used. It is, therefore, more applicable to the ton truck than to the van.