THE COMMERCIAL MOTOR OF THE NEAR FUTURE.

Page 12

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

The Concluding Section of a Survey of the Practical Improvements that are Capable of Being Immediately Adopted.

IN the first section of this article which appeared in last week's issue of The Commercial Motor, I made the assertion that there are improvements (quite apart from those which are still in the theoretical stages and which call for a certain measure of development before the claims made for them can be substantiated) which can profitably be incorporated in present-day commercial motor chassis. I dealt with crankshaft design and pointed to the particular places in a shaft which show the first signs of wear and others where fractures mvariably start. Knowledge in these matters is not so common as one might believe. .Reference was made to a number of other features of engine design, including methods of lubrication, water circulation, etc., whilst clutch construc

t i o n, radiator construction were considered from the point of view of better maintenance. The question of rendering engine starting easier than it is was also gone into. In this, the concluding part of my article. I go into further matters which, if carefully studied and the advice given acted upon, would, I feel sure, tend to the improvement of the commercial metor chassis as we know it to-day.

There seems to be a prevalent feeling that anything but the ordinary type of change-speed gear, either by sliding teeth or dog engagement, should be classed as a freak and can be dismissed right away. it is held by some that the ordinary type is perfectly satisfactory in every way, but, if one harkens to the bad changes made by many lorry drivers, and if one also has access to the repair shops, it will be seen that this is far from the truth ; something better is wanted.

The ordinary gearbox would be greatly improved by the introduction of a clutch on the propeller shaft, which would free the gears from the driving effect due to the forward movement of the car during the period of changing. This would leave both shafts free to allow the gears to engage without damage, or without skill on the part of the driver. Such clutches have been tried, but difficulties have been encountered owing to the high torque due to the reduction in the gearbox. We may hear in the near future of a magnetic clutch suitable for application to this purpose, and actuated by the clutch pedal, which would free the propeller shaft as well as the engine simultaneously. I consider that four gears are essential, and, for heavier loads, even five speeds might be worth considering, as this can easily be obtained by means of duplicating the operating wheels.

There is little need to emphasize the fact that al! B28

lorries should be fitted with brakes which should be powerful enough to hold the vehicle when fully loaded on the steepest hill. It is easy to say this, but it is not so easy to design brakes which will perform this duty. The levers of either hand or foot brake cannot conveniently work through an angle of more than 35 degrees. This, when the necessary leverage in obtained and all spring and whip taken up in the various connections, does not admit of much latitude should the lining material have compressed or worn away.

Hand brakes have been made in which, should the driver find it necessary, he can take more than one pull by means of a ratchet arrangement of suitable design. I have known cases where a driver would hate given the world to be able to take a second pull at his brake lever. The design of brake connections, so that they are unaffected by the load carried by the vehicle, is a matter that should receive more attention. Even to-day there are commercial motors in which the brakes will act well enough when the vehicle is unloaded, but will lose much of their power when the springs are depressed by a full load. In some makes the reverse action takes place, the brakes becoming weaker as the load becomes less. It is quite possible, with proper care, to design brakes so that they are absolutely unaffected by the .compression of the springs.

Oil or Grease for Small Moving Parts?

The lubrication, of such parts as shackle pins, steering heads and joints, brake connections and universal joints may seem to be but a minor matter, but bad lubrication or neglect may cause expense and delay. I have always found oil to be preferable to grease for such parts, and nothing can be better than the simple oil cup made of steel with a spring cap, which can be lifted by the spout of an ordinary oilcan and which automatically closes again.

Special grease guns and injectors for introducing oil are of little use for lorry work, as the driver generally manages to lose them in time and often fails to report their loss. In some cases he will try to push the grease in with a piece of wood or something equally useless. 1 have found nothing to heat the common oilcan, which is to he obtained everywhere.

A good deal of trouble, often entailing costly replacements, can be caused by the use of unsuitable universal joints.

More care should he bestowed on the design of these parts and better means of lubrication provided. The practice of fitting only one universal joint between the engine and gearbox is not good, as it puts a very unfair strain on the joint.

Rear Axle and Final Drive.

We now come to the most debatable point in the whole machine, namely, the rear axle and final drive. The worm has been practically abandoned in the pleasure ear on account of its law efficiency, compared with bevel wheels. It is well recognized that the worm as a drive is less efficient at low speeds than at high speeds, owing to the fact that, at low speeds when the torque is heavy, the oil is pressed from between the fazes of the worm and the teeth of the wheel, resulting in metallic contact taking place. This is the theory, but in actual practice it is evident that there is net much metallic contact taking place, or we should find a worm box, after long use, containing a large quantity of fine granulated bronze. I am, however, of the opinion that we should get higher efficiency if we could use bevel gears for a first reduction of, say, two to one, and a further reduction of some kind such as that shown in Fig. 6, which is actually in use to-day on light lorries and electric vehicles. There are doubtless 'difficulties to be overcome before this class of drive becomes satisfactory enough to be adopted as a standard, but, taken as a whole, it has many good points, amongst which are the following:—

All load on gears equally balanced; (2) three points of contact driving at once, in both driver and driven gears ; (3) high ground clearance for work on bad roads and for Colonial use.

Next we come to the nature of the drive from the gearbox to the rear axle. This is, perhaps, a point on which there is more difference of opinion among designers than an any detail of a chassis.

Certain firms cling to certain types. One has used torque tubes and found them satisfactory ; another has used radius rods with success, another has used the springs for both radius and torque and encountered little trouble. In many cases each firm has kept to its standard practice and has tried no other. Personally, I am in favour of letting the springs do all the work usually divided between torque and radius rods.

Allowing the Springs to Take the Torque and the Drive.

It is said by some that this design is wanting in rigidity That is exactly why I consider it the best plan. Provided that proper provision is made for flexibility, rigidity is not wanted in the chassis of a lorry, and provided that the springs are strong enough ta bear the load, they should be strong enough to resist all strains due to torque from the drive or from the brake reaction.

There is still room for improvement in the construction of frames. We are told that with a deep section of pressed frame no bracing of any kind is required. My own experience shows me that there is less trouble from broken side members with frames that are made of ordinary channel steel fitted with a welldesigned brace, than with even a deep section nickelsteel pressed frame. I can only attribute this to the fact that the channel has flanges •which are of a thicker gauge than the vertical web, and that there is a radius in the corner which adds to the thickness of the metal at that part. That. broken frames are not unknown was brought home to me recently when examining a large fleet, as I was surprised to see the very high nercentage of frames which had broken just behind the engine and had been patched there. There has been a strong feeling against braced frames among certain en. gin eers in the past, but I think they will be looked upon with more favour in the future. The objection to bracing was probably due to the fact that railway practice was followed and that the braces acted only in tension and were usually adjusted by means of a turnbuckle.. In many eases the turn buckle was neglected and the stay-rod was allowed to dangle loosely and to increase the general rattle. When a lorry was loaded in such a way that a great portion of the load came on to the rear end of the platform, an when long girders are carried, the stay became inoperative, and in some cases the tie-rod would sag and leave the horns into which it fitted. For a stay to be useful in all circumstances it should be made of a section that will bear compression, and should be fixed by rivets at both ends also to its struts.

The use of rivets in any other part of a frame but the brace is a practice that is open to criticism. Many owners of large fleets will stipulate, when giving orders, that no rivets are to be used. Anyone who has had to straighten up a heavy lorry frame after an accident will appreciate the wisdom of this.

It can hardly be said yet that wheels of aluminium alloy have proved beyond all doubt their suitability for use on lorries, but there are many instances where they are giving great satisfaction. It would be well, therefore, for designers to keep a close watch on them. Such wheels have the advantage of very considerably reducing unsprung weight.

More Thought to the Sprag Required.

The need for some device which will prevent a runaway backwards is a matter that has received all too little attention and has been dealt with in a very careless manner. The ordinary trailing sprag is of very little use, as, generally, a driver does not realize the necessity for its use until it is too late. I have known the trailing sprag to fail through getting in a tramline, The ratchet type, which can be brought into action_ by means of a lever, is little better, as the average driver does not put it into action early enough to be of any use. There is at least one device on the market suitable for use on lorries, which is normally in action, and is thrown out by a connection with the reverse lever. It has a number of pawls, which are held out of action whed the reverse gear is put into operation. This device is very useful to drivers of heavily loaded wagons who are trying to get going on a steep hill. The filtering of air as it comes into the carburetter is another matter which has received little attention here. It is true that on English roads of to-day there is very little dust, but it should be remembered that a useful lorry should be able to operate in other lands besides this Even with our own practically dustless roads, no working parts such as bearings, slides, etc., would be allowed to be open to the dust of the road. The steam lorry makers are now recognizing this, and are covering nearly all the working parts of their vehicles. It is strange that the petrol engine should have given such good results, when one realizes that the cylinder walls are open to all the dust that may be blowing about. It is well known that the so-called carbon deposit found in cylinders is largely composed of road dust. Many lorries have to operate in quarries, sand pits, and such places where grit abounds. I think it would be well if the matter of air filters were seriously looked into here.

From the nature of the jack supplied with almost any lorry, one would think that its use was never contemplated when the lorry was designed ; it appears to be an afterthought, as no place is provided on either axle for its use. In the case of large pneumatic tyres, many of the jacks supplied are useless, as they are not made for the high lift rendered necessary by the use of large tyres. I think it would be an improvement, and would certainly look more complete, if a proper provision were made on both axles

for the 'reception of the jack and for its steadying when in place. Fig. 7 is a suggestion of a dovetail slot which has been been found effective.

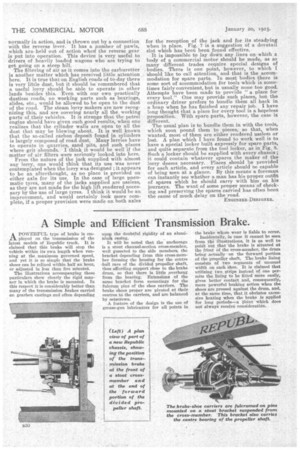

It is impossible to lay down any lines on which a body of a commeraial motor should be made, as so many different trades require special designs of bodies. There is one point, however, to which I should like to call attention and that is the accommodation for spare parts. in most bodies there is some sort of accommodation for tools which is sometimes fairly convenient, but is usually none too good. Attempts have been made to provide "a place for every tool." One may provide such places but the ordinary driver prefers to bundle them all back in a heap when he has finished any repair iob. I have long thought that a place for every tool is a hopeless proposition. With spare parts, however, the case is different.

The usual plan is to bundle them in with the tools, which soon pound them to pieces, so that, when wanted, most of them are either rendered useless or lost. A plan which I have found to work well is to have a special locker built expressly for spare parts, and quite separate from the tool locker, as in Fig, 8. Such a locker should be supplied with every chassis ; it could contain whatever spares the maker of the .lorry deems necessary. Places should be provided for each article, and every article should be capable of being seen at a glance. By this means a foreman: can instantly see whether a man has his proper outfit of spares which he should carry with him on his journeys. The want of some proper means of checking and preserving the spares carried has often been the cause of much delay on the road.