IP THAT ST

Page 52

Page 53

Page 54

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

Dodge 7-tonner Put Through Gruelling Three-day Test : Bad Conditions and Overloading have Little Effect Leyland Oil Engine Provides Ample Power

FOG, ice and snow made conditions particularly difficult when testing the Dodge forward-control 7-ton tipper, both on and oil the road, but despite these adversities the tests showed that this is one of the most rugged vehicles of its type at present manufactured in quantity in Great Britain. Not that the weather unduly affected •the occupants of the cab, for a most efficient heating system successfully counteracted the temperatures below freezing point that prevailed during the three-day test.

The additional margin of strength built into the chassis is such that the manufacturers themselves are prepared to accept an overload of 20 per cent., subject to the provision of suitable tyres. Like any other manufacturer, Dodge Bros. (Britain), Ltd., are fully aware that all their chassis are liable to be overloaded and the 7-tonner virtually becomes a 14-ton gross chassis and with a specification to match.

Some idea of the arduous conditions under which a vehicle of this type is expected to work was gained from a Morning spent on the site of the London-Yorkshire motorway, Where heavy clay is being excavated to form a cutting on the new road. Few vehicles could be expected to operate on this kind of job for more than a few weeks without trouble, but if any could, I would lay my money on the Dodge, which has the chassis frame and suspension to haul concentrated loads weighing at least 9 tons over uneven surfaces and up steep gradients.

Although it is heavier than other 7-ton tipper chassis in a similar price range, this is not detrimental in terms of running economy. Even when carrying a payload of nearly 81 tons, the vehicle returned 12.6 m.p.g. over an undulating route at an average speed of 27.6 m.p.h., which is a favourable figure with a gross weight of well over 13 tons.

Safety has not been neglected either, for the braking system of the test vehicle was air-hydraulic, which is an alternative to the standard vacuum-hydraulic system. Unfortunately it could not be tested to the full because of dangerous road conditions, but it is undoubtedly powerful enough to cope with any practicable overload, whilst the use of a conventional brake pedal ensures fully proportional braking at all times.

The frame has 15T-in.-thick side members, with a maximum depth of 10 in., and 3-in. flanges. Five cross-members, c16

two of which are, alligator-jawed boxed top-hat sections, are riveted in position to make the frame exceptionally rigid, whilst spring-hanger beackets and so forth are bolted.

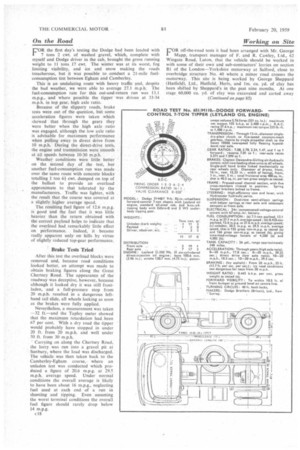

A choice of two power units is offered in the chassis. One is the Leyland 0.350 5.76-litre 105 b.h.p. oil engine (as tested) and the other the Perkins R6 Mk.2 5.56-litre unit, which develops 104 bh.p. With either engine a fivespeed constant-mesh gearbox with direct-drive top gear is specified.

The standard single-speed spiral-bevel rear axle has ratios of either 6.16 or 6.66 to 1, but two Eaton two-speed axles are available. These are the 16800, which has ratios of 5.62 and 7.81 to 1, or the 18500, 'which is offered with ratios of 5.571 and 7.599 to 1 or 6.5 and 8.866 to 1. The 18500 axle, which was fitted to the test vehicle, is recommended when overloading is expected.

tat-rate semi-elliptic springs are employed at both , the front springs being 50 in. long and the rear 48 in. Helper springs can be fitted at the rear axle for oad and stability purposes, and telescopic dampers are able for the front axle. Such dampers are also offered he rear axle, except, as in the case of the test vehicle, an 18500 two-speed axle with electric shift is fitted. electric shift is employed when air-hydraulic brakes pecified.

e front axle is rated for a loading of 4 tons and the efficiency cam-and-lever steering gear has a ratio of 20 to I. Hydrosteer power assistance for steering is standard and is particularly useful on a forward-control tipper, the front-axle loading of which is naturally higher than that of a normal-control design. Power steering is an alternative to the employment of low-ratio steering gear, which necessitates more turns of the wheel from lock to lock.

An all-steel cab is standard on the Dodge forward-control range and is flexibly mounted on the chassis frame at four points. Features include a wide one-piece curved windscreen, rear quarter lights, double-skinned rear panel and lined roof. Smiths heating equipment is available. It consists of fan units at each side of the cab, which can be used to warm the interior with either fresh or recirculated air, or to draw in fresh cool air. Its efficiency, and that of the accompanying four-duct demisting system, was both marked and welcome during the test.

A standard Dodge 6-cu.-yd. timber tipping body with metal-lined floor was fitted to the test vehicle. The normal tipping gear provided is the Edbro-B. and E. W3 underbody type, which has two telescopic rams side by side to give a high measure of lateral stability when tipping.

L'OR the first day's testing the Dodge had been loaded with

7 tons 2 cwt. of washed gravel, which, complete with myself and Dodge driver in the cab, brought the gross running weight to 11 tons. 17 ewt. The winter was at its worst, fog limiting visibility, and ice and snow making the roads treacherous, but it was possible to conduct a 21-mile fuelconsumption test between Egham and Camberley.

This is an undulating route with heavy traffic and, despite the bad weather, we were able to average 27.1 m.p.h. The fuel-consumption rate for this out-and-return run was 13.1 m.p.g., and where possible the tipper was driven at 33-34 m.p.h in top gear, high axle ratio.

Because of the slippery roads, brake tests were out of the question, but some acceleration figures were taken which showed that through the gears they were better when the high axle ratio was engaged, although the low axle ratio is advisable for maximum performance when pulling away in direct drive from 10 m.p.h. During the direct-drive tests, the engine and transmission were smooth at all speeds between 10-30 m.p.h. Weather conditions were little better on the second day of the test, but another fuel-consumption run was made over the same route with concrete blocks totalling 1 ton 64cwt. dumped on top of the ballast to provide an overload approximate to that tolerated by the manufacturers. Traffic was lighter, with the result that the course was covered at a slightly higher average speed. The resulting fuel figure of 12.6 m.p.g. is good and the fact that it was little heavier than the return obtained with the correct payload helps to indicate that the overload had remarkably little effect on performance. Indeed, it became really apparent only on hills by virtue of slightly reduced top-gear performance.

Brake Tests Tried After this test the overload blocks were removed and, because road conditions looked better, an attempt was made to obtain braking figures along the Great Chertsey Road. The appearance of the roadway was deceptive, however, because although it looked dry it was still frostladen, and a full-pressure stop from 20 m.p.h. resulted in a dangerous lefthand tail slide, all wheels locking as soon as the brakes were fully applied. Nevertheless, a measurement was taken -32 ft.-and the Tapley meter showed that the maximum retardation had been 67 per cent. With a dry road the tipper would probably have stopped in under 20 ft. from 20 m.p.h. and well under 50 ft. from 30 m.p.h. Carrying on along the Chertsey Road, the lorry was run into a gravel pit at Sunbury, where the load was discharged. The vehicle was then taken back to the Camberley-Egham course, where an unladen test was conducted which produced a figure of 20.6 m.p.g. at 29.5 m.p.h. average speed. Under normal conditions the overall average is likely to have been about 16 m.p.g., neglecting fuel used at each end of a run in shunting and tipping. Even assuming the worst terminal conditions the overall fuel figure should rarely drop below 14 m.p.g.

c 18

FOR off-the-road tests it had been arranged with Mr. George Mapp, transport manager of F. and R. Cawley, Ltd., 62 Wingate Road, Luton, that the vehicle should be worked in with some of their own and sub-contractors' lorries on section BI of the London-Yorkshire motorway at Salford, close to overbridge structure No. 40 where a minor road crosses the motorway. This site is being worked by George Sheppard (Hatfield), Ltd., Hatfield, Herts, and lm. cu. yd. of clay has been shifted by Sheppard's in the past nine months. At one stage 60,000 cu. yd. of clay was excavated and carted away

weeks, and all the haulage has been sub-contracted to Cawley fleet totals 17 vehicles, including five Dodge )rward-control 6-ton tippers and three Dodge semi'd-control 7-ton tippers, all with oil engines. The transport Cawley's was started eight years ago with five tippers. journey from Luton to Salford was made over icy roads, n ambient temperature of 28F. Despite the relatively ear-axle loading—a feature sometimes held against d-control tippers—only once or twice was rear-end noticed, although the vehicle was being cruised at 5.h. for the most part. The approach to the excavation mil the road was made down a smooth gradient of about 5 and, although the ground was frozen hard, the wintry ade the top surface slippery. Even walking was difficult. Ruston Bucyrus 22-RB draglines with f-cu.-yd. buckets, with a Caterpillar bulldozer, are normally employed tding operations on this section, although one of the s was temporarily out of action while we were on the The clay being loaded had a high water and ice content ach bucket load must have weighed in the region of s.

ing our turn in the queue. the Dodge was backed up IS the excavator and a certain amount of wheelspin was ,need. Once in position, six bucket-loads were emptied Le body, and the tipper was driven from the site without difficulty and across to the tip some four miles away.

Precautions Against Sticking .

prevent the wet clay from sticking when tipped, the of the body had been swilled out with derv. The n of this precaution was seen at the tipping site, because idy had to he elevated to at least 45° before the load I to move. Once 'it did move, however, the weight of it I the pivot point brought the body up with a bang, ing the rains to their full extent and imposing a great on the body, its underframe, tipping gear and the chassis. ; type, of load is one of the most damaging that can be I. Bodies have often been ripped from the chassis and ; gears wrecked because of the impact of the body when ily tipped as the load moved, and, as witnessed on the little carelessness can even result in the vehicle standing its rear wheels.

Dodge was then returned to the site for a second load is time I drove. Backing into position under the dragas not as easy as it looked. Only a narrow pathway had smoothed out by the bulldozer and, not realizing how space there was on the near side, I drove too far to Ott with the result that I got on to the rough stuff and heel traction was lost.

ertain amount of see-sawing and manual labour was ary to get clear, although the wheelspin experienced not have occurred had the tyre pressures been lower. -ear-axle loading when empty is, however, one of the L generally aimed against a forward-control design for bucket-loads were then emptied into the body, giving a Ld of about 9 tons, despite which the vehicle was easy

to drive out on to the road. The steering power assistance made light work of pulling the front wheels out of the ruts and so forth. Between the site and the tip the Dodge was well able to keep up with other traffic despite the large overload and, although the engine was obviously working hard, there appeared to be plenty of power in hand.

The only difficulty experienced in tipping was in freeing the locking cam bar which secures the bottom of the tailboard. The pressure of the clay inside the body forced the tailboard against the bar and made it difficult to release the securing chain. Normally, pins are put in the two lower hinge brackets to secure the tailboard, but as these had already been found difficult to remove on previous occasions they had been left out for this run.

Handling Characteristics

TAKEN generally, the Dodge 7-ton tipper is a pleasant vehicle to drive, although the short gear lever is set back rather a long way and calls for an awkward stretch when changing gear, particularly when using second and third ratios Engine-cowl insulation is most effective, thus relieving the driver of noise fatigue.

The power steering works well and, although its setting is such that the wheels can be moved when the vehicle. is stationary, the amount of " feel" when travelling on the road at normal speeds is not unduly low. In the straight-ahead position there is a slight tendency to wander which demands constant correction at the wheel and can at first be disturbing. Although not tested to the full, the brakes felt dependable and the use of a long-travel pedal is much preferable to the treadle type often encountered with air-hydraulic systems.

Good Suspension

Both laden and unladen, the suspension gave a good ride and when running over rough surfaces without a load the absence of cab and body rattles was noteworthy, suggesting that the dual-rate suspension should give marked benefits in respect of increased chassis life. The seats are comfortable, the driver's seat being adjustable fore and aft and vertically, although I would prefer a little more support for the small of the back.

All the instruments are centrally grouped and marked in white characters on a black background. I was particularly impressed by the side and headlamp switch, which is of the finger-tip "flap" type mounted on a stalk protruding from the right of. the steering column. It makes it easy to give light signals to other drivers and avoids the long stretch so often encountered on commercial vehicles.

The basic Dodge 7-ton tipper chassis, with Leyland oil engine and the standard cab. costs £1,718 and in Great Britain £377 7s 8d. purchase tax is payable. The 6-cu.-yd. tipping body and gear add a further £220 to the basic price and other extras fitted to the test vehicle included the Eaton 18500. two speed axle with electric shift (£172 10s.); 10.00-20-in. (17-ply) tyres (41 17s, ltd.); front damPers (£7 16s.3d.); rear, helper springs (£10); air-hydraulic brakes (£67 10s.); cab heating, and demisting gear (£20 10s.); and flashing direction indicators (£10).