HINTS ON MAINTENANCE.

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

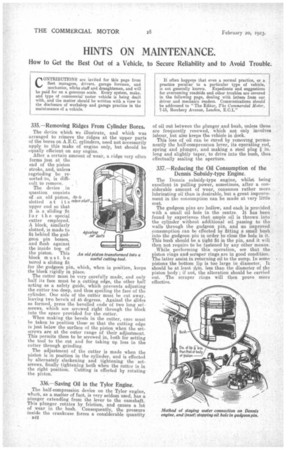

The device which we illustrate, and which was arranged to remove the ridges at the upper parts of the bores on A.RC, cylinders, need not necessarily apply to this make of engine only, but should be equally efficient on any engine. After a certain amount of wear, a ridge very often forms just at the end of the piston stroke, and, unless regrinding be resorted ,to, is difficult to remove.

The device in question consists of an old piston, filn/o slotted at i t a upper end so that it is a sliding fit for the special cutter employed. A block, similarly slotted, is made to fit behind the gudgeon pin bosses, and flush against the inside top of the piston. This block must. be bored a sliding fit for the gudgeon pin, which, when in position, keeps the block rigidly in place.

The cutter must be very carefully made, and only half its face must be a cutting edge, the other half acting as a safety guide, which prevents adjusting the cutter too deep, and thus spoiling the face of the cylinder. One side of the cutter must be cut away. leaving two bevels of 45 degrees. Against the slides so formed, press the bevelled ends of two long setscrews, which are screwed right through the block into the space provided for the cutter. When making the bevels in the cutter, care must be taken to position these so that the cutting edge is just below the surface of the piston when the setscrews are at the outer range of their adjustment. This permits them to be screwed in, both for setting the tool to the cut and for taking up loss in the cutter through grinding

The adjustment of the cutter is made when the i piston is n position in the cylinder, and is effected by alternately slackening and tightening the setscrews, finally tightening both when the cutter is in the right position. Cutting is effected by rotating the piston. An old piston transformed into a useful cutting tool.

336.—Saving Oil in the Tylor Engine.

The half-compression device on the Tyler engine, which, as a matter of fact, is very seldom used, has a plunger extending from the lever to the camshaft. This plunger rotates by friction, and causes a lot of wear in the bush. Consequently, the pressure inside the crankcase forces a considerable quantity B42

of oil out between the plunger and bush, unless these are frequently renewed, which not only involves labour, but also keeps the. vehicle in dock.

This loss of oil can be cured by removing permanently the half-compression lever, its operating rod, spring and plunger, and making a steel plug in. long and slightly taper, to drive into the bush, thus effectually sealing the aperture.

337.—Reducing the Oil Consumption of the Dennis Subsidy-type Engine.

The Dennis subsidy-type engine, whilst being excellent in pulling power, sometimes, after a considerable amount of wear, consumes rather more lubricating oil than is desirable, but a great improvement in the consumption can be made at very little cost.

The gudgeon pins are hollow, and each is provided, with a small oil hole in the centre. It has been found by experience that ample oil is thrown into the cylinder without additional oil passing to the walls through the gudgeon pin, and an improved consumption can be effected by fitting a small bush into the gudgeon pin in order to close the hole in it. This bush should be a tight fit in the pin, and it will then not require to be tastened by any other means.

While performing this operation, see that the piston rings andscraper rings are in good condition. The latter assist in returning oil to the sump. In some pistons the bottom lip is too large in diameter. It should be at least *in. less than the diameter of the piston body ; if not, the alteration should be carried out. The scraper rings will then prove more effective. In certain instances breakages have occurred in the overhead water return pipe, which is only supported by the short length of hose at each end. In time, as this hose deteriorates, the weight of the pipe and the vibration cause it to sag and possibly to break. Such an annoying incident may be prevented by

fitting a stay support in the centre of the pipe. This support can be carried from the second stud of the water-jacket cover, using an extra long nut and forging out the end of a ft-in. bolt to about lar, in. thickness, shaping it to fit underneath the pipe. The last-named can be held in position by a clip.