You bend 'em %Iwo mends 'em

Page 30

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

I Gordon Murray

HE Yorkshire Engineering and lidding Co Ltd has specialized in uilding bulk tanks for transporting oil, hemicals and foodstuffs since 1947. row the company is no longer in usiness as a tank manufacturer but istead is concentrating its resources on ffering operators of road tanks a 24our repair and service facility.

The decision to make the transition :om builder to repairer was taken arlier this year as a direct result of the rowing demand from operators for pecialist repair, rebuilding and lodification of existing tank units.

Situated at Idle. Bradford, about .8km (3 miles) from M606 and within asy reach Ml, M6 and M62 the ompany is able to provide a countryiide service and provide collection and elivery for any type of tank or trailer up o 32.5 tonnes (32 tons). The 2,043sqm 22,000 sq ft) workshop is fully ey uipped nd manned to deal with any repair or aodification to any type of tanker or • ehicle including chassis work and the itting of pumps and fire screens to ractive units.

Facilities available to operators nclude fully approved steam cleaning Lnd degassing equipment for any type of 'chicle or tanker, a pump test rig and veights and measures approved :alibration of tanks, and, of course, a upply of spare parts.

In addition, Yewco can undertake to upply and fit hydraulic systems for iriving pumps and compressors on rigid nad tankers and tractive units, as well LS tank trailers in the case of articulated ankers.

rank mods advice

Already the company is building up a .eputation for service, and operators are :oming along to ask advice on tank nodifications which include lengthenng or shortening and changing multi:ompartment to single or vice versa.

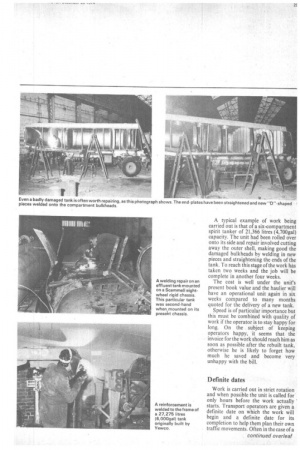

Some of the modification and repair work carried out by Yewco is pretty drastic but the managing director, Mr S. Ly. Wood, says that the economics are iuch that a unit has to have a very low book value or be extremely badly damaged for the work not to offer the operator considerable savings on the cost of a new unit. A typical example of work being carried out is that of a six-compartment spirit tanker of 21,366 litres (4,700gal) capacity. The unit had been rolled over onto its side and repair involved cutting away the outer shell, making good the damaged bulkheads by welding in new pieces and straightening the ends of the tank. To reach this stage of the work has taken two weeks and the job will be complete in another four weeks.

The cost is well under the unit's present book value and the haulier will have an operational unit again in six weeks compared to many months quoted for the delivery of a new tank.

Speed is of particular importance but this must be combined with quality of work if the operator is to stay happy for long. On the subject of keeping operators happy, it seems that the invoice for the work should reach him as soon as possible after the rebuilt tank, otherwise he is likely to forget how much he saved and become very unhappy with the bill.

Definite dates

Work is carried out in strict rotation and when possible the unit is called for only hours before the work actually ' starts. Transport operators are given a definite date on which the work will begin and a definite date for its completion to help them plan their own traffic movements. Often in the case of a damaged multi-compartment tank, where damage is confined to one compartment, so long as it is not No I compartment, the unit can be kept operational rather than standing idle. If No I compartment is empty and the rest loaded the vehicle becomes unstable.

Naturally, there are emergencies in the best run establishments and these are taken care of by building "float" time into what are called routine job times. In order to protect the system a surcharge is applied to ensure that any operator who insists on having his job pushed through really needs this facility.

As already mentioned any type of tank refit can be carried out and, interestingly, not all operators are looking for more capacity.

One in particular had jumped the gun in ordering a tank built for operation at 40.6 tonnes (40 tons) with a six-wheel tractor and had been operating the outfit below its capacity: he wanted the tank shortening to match his new, smaller tractive unit.

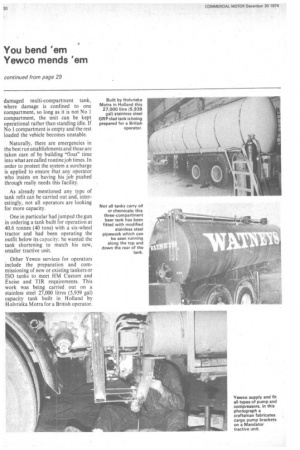

Other Yewco services for operators include the preparation and commissioning of new or existing tankers or ISO tanks to meet HM Custom and Excise and TIR requirements. This work was being carried out on a stainless steel 27,000 litres (5,939 gal) capacity tank built in Holland by Holvrieka Motra for a British operator.