MAKING STEEL BY ELECTRICITY.

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

Britain Leads in the Production of High-grade Steels Suitable for Motorvehicle Construction and Tool-making.

A',THOUGH the actual making of steel may not be of general interest to the majority of our readers, we cannot help thinking that, when an outstanding step in the direction of obtaining better steel is made by a British firm, it ust be of interest to all who use mechanical road transport, and we feel sure that this matter will be of importance to those who may be concerned in the mai ufacture of automobiles of all kinds. •

It is now commOn knowledge, even to the untechnical, that all the part of automobiles such as shafts, gears, etc., have to be r4iachined to their accurate dimensions by means of cult g. tools. These tools or cutters are made of a speci 1 quality of steel which must be capable of being rendered extremely hard. The steel must have sufficient strength to bear the strain of cutting metal and above all, it must be of such a grade that it will retain a fine edge.

Sheffield has always excelled in, and maintained a world-wide reputation for, the manufacture of such steels. Great imProvements have recently been made in these steels by alloying them with tungsten and other metals, by means of which the strength of the steel is greatly increased, whilst, without reducing the hardness of the cutter or tool, the speed of cutting may be increased to an extent unheard of with ordinary tool steels. So great s the speed at which such tools can be made to cut, Without damage to their temper, that the particles of Metal cut off, " chips," as they are called, will have generated so much heat in being cleaved from the bulk of the metal that they will oxidize and turn blue ; hence the name " high-speed " applied to the metal.

Another comparatively recent development which is finding its way into motor construction is " stainless steel." In the Manufacture of .all these high-grade steels it is most essential that the metal while being melted should not come into contact with the fuel or its gases. With this object in view many electric furnaces have been recently invented, but, for the production of the highest grades, of steel, they did not entirely produce the effect required.

The firm of Edgar Allen and Co., Ltd.. Sheffield, has always been assoeiated with the manufacture of high

grade steels, and it is with great pleasure that we are enabled to record the fact that this British firm is the first in the world to install the new process of melting steel by what can justly be described as " wireless " anti, strange to say, in the centre of a wooden box, the heat being produced in the steel itself, which is in a crucible, and not transmitted through the walls of the crucible, as with other systems, thus preventing the ingress of those deadly enemies of high-grade steel, sulphur and phosphorus.

Description of the Process and the Apparatus.

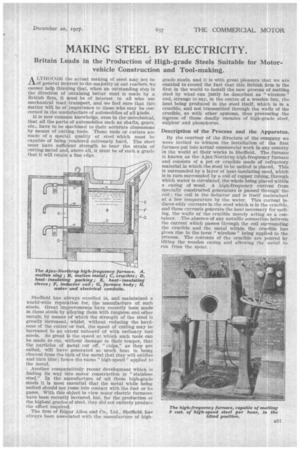

By the courtesy of the directors of the company we were invited to witness the installation of the first furnace put into actual commercial work in any country in the world at their works in Sheffield. The furnace is known as the Ajax-Northrup high-frequency furnace and consists of a pot or crucible made of refractory material in which the steel to be melted is placed. This is surrounded by a layer of heat-insulating sand, which is in turn surrounded by a coil of copper tubing, through which water is circulated, the whole being placed within a casing of wood. A high-frequency current from specially constructed generators is passed through the coil; the coil is the inductor and is itself maintained at a low temperature by the water. This current induces eddy currents in the steel which is in the crucible, and these currents generate the heat necessary for melting, the walls of the crucible merely acting as a container. The absence of any metallic connection between the current which passes through the coil surrounding the crucible and the metal within the crucible has given rise to the term " wireless " being applied to the process. The contents of the crucible are poured by tilting the wooden „casing and allowing the metal to run from the spout. ;