SIXTY THOUSAND MILES iG WITH SIX-WHEELERS.

Page 14

Page 15

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

EVIDENCE is available in many directions to show that interest has been fully aroused among manufacturers and users in the sixwheeled vehicle. So long ago as August, 1920, we described and illust, ,ted a practical application of the principle, and it is more than interesting to note that this took the form of a passenger coach designed to run on pneumatic tyres, for this is the line .upon which we confidently expect that development will procoeel in the immediate future, to be quickly followed by the goods vehicle. We .io no hark back farther than the reference of August, 1920, because, prior to that date, inventors and designer:: had not, in our opinion, shown a full appreciation of the conditions with which they had to deal, nor with the ultimate aim of the advance upon.recognized forms.

These conditions and requirements mu.A be kept in the forefront the whole time. Whilst spreading the load over more points of contact, it is important that, instead of weight and cost being increased, the opportunities afford e4 lay the adoption of that principle should be grasped with the deliberate intention of actually reduting them, if possible. A combination of lightweight components, cheaper and quicker to 2nanufacture in proportion to the more powerful sets, will, without doubt, do the work of the latter quite satisfactorily. In .assembling thE components, and in their erection in the chassis, lightness of the units must, obviously, mean quicker output and lower labour costs.

Because the six-wheeled chassis cannot now be produced at the same cost as, and weighing no more than, the four-wheeled chassis. there is no reason why it should not eventually be done. No attention has yet been paid by British manufacturers tor the attainment of the ideal. Yet there is ample genius among P.itish, French, Italian and American designers to enable them to find the solution to the problem, and we go so far as to say that it will be. found much quicker than is expected. We were able, in our issue of last week, to give a suggested design which showed a distinct advance in thought, and in our next issue we intend to deal further with that particular subject, going more fully into details of the design.

In the United States the Government has shown an intense interest in the six-wheeled vehicle, the object being to ascertain if the type would assist in the problem confronting the various highway authorities of

securing better roads at less cost. At the instigation of the representative of the Government, the mem bers of the American Society of Automatic Engineers appointed a committee at the annual meeting in June last to study multi-wheeled design. Here is an example to be followed by file Roads Department of our Ministry of Transport and the Institution of Automobile Engineers. Will Sir Henry Maybury,

that great practical modern road builder, take the lead in this direction ? We can imagine no snore useful application of energy.

The paomise of .encouragernent from the Ministry would provide the incentive to designers and manu facturers. The promise of a measure of relief from motor taxation, in the case of such vehicles as the Ministry is satisfied cause less wear and tear of the roads, would, we are certain, be rich in effect. The user would welcome such relief and would be prepared to buy the improved yea.icle. He would recognize that reduced wear and tear of the road must mean reduced wear and tear of the vehicle. Smoother running would result in lessened tyre wear and lower petrol consumption. Main tenance charges would fall, reliability would be increased, and there would be less idle time whilst the vehicle was under repair or being overhauled. The effect of all these advan tages in the cost of running would be so marked that, for the time being and until prices could, by reason of greater demand and larger output, be brought down, any initial extra cost would be of small importance, because the increase in capital charges would be more than compensated by the reduction of running costs. The appeal to the user would be so strong that the motor industry would be encouraged to design and manufacture the new type of vehicle, knowing, moreover, that there is an influential and extensive class of user which is keen on "something new," particularly when it .offers material advantages such as we have indicated.

The coach proprietor is essentially a type of user on the look-out for " thevehicle that is different." He recognizes that there is a large body of custom always responsive to the call of greater comfort and better

style—the call of superiority. A refined chassis and a high-class coach body and, in a lesser degree, pneumatic tyres have, so far, constituted the limits of his vision. To-day there is opened to him the prospect of a type of vehicle which must, of necessity, stand out ; one which, because of the reduction of load per wheel, brings the pneumatic tyre more into the realms

of practicability.. And the tenderness. of the human frame

finds its counterpart in the fragility of certain goods and wares. Many a load to-day is taken carefully and slowly which could be speeded on its way in a pneumatic-tyred van. So much for thep user, who, of course, is a highly important factor in this development. Looking in another direction, those wile are responsible for the maintenance a our roads would, surely, go so far in the matter of welcoming a type of vehicle that caused less road damage per unit of load that they would seek to encourage its use by urging upon the Ministry its claims to taxation relief. In face of air this encouragement, there is every reason why designers and manufacturers should at once approach the problem, and to aid them in their deliberations we would point to the extremely valuable work accomplished by the experimental department of the Goodyear Tyre and Rubber Co., of Akron, U.S.A. When the pneumatic tyre was first brought out for commercial goods vehicles and paseenger-carrying vehicles of large capacity, it was seen that, in order successfully to carry the load, the tyree would have to beanade of substantial dimensions. These dimensions have settled down to 38 ins. by 7 ins., 40 ins. by 8 ins., 42 ins. by 9 ins., 44 ins. by 10 ins., and 48 ins. by 12 ins. and they introduced obvious difficulties such as handling in fitting, inflation, cost, etc. Each difficulty was gradually overcome or diminished in effect, however, and to-day few doubts exist concerning the practicability of the large pneumatic. But, during the war," it occurred to the Goodyear Co. that, in order to carry a five ton paying load, pneumatic tyres in tandem might be used to advantage. It was impossible at that time to interest the motor manufacturers in the idea, so the Goodyear Co. instructed its experimental 'department to go ahead and ascertain the possibilities of the scheme. The experiments have been fairly extensive, as three or four 'different types of tandem rear axle sets have been 'produced and the vehicles have been driven over con

siderable distances in ordinary commercial work. •

Spreading the weight that usually falls upon two wheels over four, bringing the tandem axles so close together that the treads of the tyres on adjacent wheels are not more than 6 ins, apart, and avoiding any differential action between the wheels on the one axle and the wheels on the other, tyre wear was found, in the course of the experiments, to have been reduced to such an extent that distances in excess of 14,000 miles per tyre have been given, whilst the fact that a vehicle with a 5 ton paying load consumed only one American gallon (which is five-sixths of an

. English gallon) per 6.5 miles showed that no impairment of the efficiency of the transmission had been caused by the additional mechanism.

Three possible difficulties in connection with the employment of more than four wheels always crop up when the subject comes on for discussion, These are (1) the increase of weight, (2) the increase of cost, and (3) the tendency for the wheels on one axle to slip when travelling in a curve. The Goodyear Co. are prepared to show that all three of these difficulties are exaggerated.

Why There Need be No Added Weight.

Taking the question of added weight, first of all. For vehicles of 5 tons capacity, two driving axles of 2 tons capacity were used in place of the 5 ton axle, and in some of the dpsigns the two axles were only of 1.1tons capacity. These are still in use and are rendering good service at the end of 20,000 miles running-under test conditions, as much as 9 tons of load having been carried at times. The weight of two 2 ton axles works out at about 1,860 lb., whereas the average weight of a 5 ton axle is about 1,820 lb. However, a great saving can be effected by the employment of pneumatic tyres and the suitable -wheel equipment, those employed on the two light axles weighing 1,416 lb. complete, whilst those on the 5 ton axle weigh 1,830 lb. complete, or a weight saving of 414 lb., or 374 lb. net. Th-, unsprung weight of any one wile is, obviously, considerably lessened. Taking now the question of cast. 1n-the States, where the business of manufacturing component parts upon a large scale has grown to wonderful dimensions, and where the 2 ton and 21. ton commercial vehicles are extremely popular types, the cost of axlestsuitable for such vehicles is very much lower in comparison with that of the 5 ton axle assembly, so that the total cost of two rear axles of the smaller type is not materially differeet frdra that of the single 5 ton axle, the difference in America being 57 dollars in the case of internal gear drive and only 35 dollars in the case of worm gear axles. Any comparison of British costs should produce practically similar results.

Small Higher -Cost Includes Pneumatics.

The cost of pneumatic tyres is, of course, greater than the cost of solid tyres, and this is where the difference really comes in. The difference, in the States. between a set of solid tyres for a four-wheeled lonry and a set of large pneumatics for a six-wheeled vehicle is about 450 dollars, so that the total extra cost would be about 500 dollars, or at, say; 4 dollars to the pound sterling, the equivalent of about 2125. It is expected that this difference will be reduced.

Before dealing with the important question of wheel slip, it would be as well to describe the tandem back axle assembly. In the case of the goods vehicles (of which six had been constructed for experimental purposes up to a few weeks ago), a wheelbase, from the centre of the front wheels to the centre between the rear Wheels, of 15 ft. was adopted. The engine was four-eylindered, 5 ins, bore by 6 ins, stroke, developing 40 h.p. at 1,200,r.p.m. The gearbox gave six forward and two reverse gears, the forward gear ratios being 5.8 to 1, 10 to 1, 20 to 1, 23.2 to 1, 35.7 to 1, and S2 to 1. The rearaxles were two standard 2 ton components with overhead worm drive, or i ton axles with internal gear drive. In each case the 'tandem axles are carried at the ends of inverted cantilever springs, pins on the

brackets bolted to the axle casings passing through eyes at the ends of the two bottom leaves. The springs are bolted at their centres to the chassis frame. Two different methods of absorbing the driving torque are employed. In the case of the worm-driven assemblies, a pair of linked forgings, hanged for lateral movement to forgings bolted to the differential casings of the axles, is used, whilst, in the case of the axles with internal gear drive short sleeves are mounted on each axle connected together by means of two twin plates so arranged that a certain amount -of end-to-end freedom is permitted. The dead, or load-carrying, axle in front of the assembly is dropped in the centre to afford room for the driving shaft to pass through from the forward to the rearmost axle.

Ample 'brake power is pro vided, as there are four pairs of brakes -of 21 ins.

diameter by 2?,. ins, in width, each pair in a. brake drum 51 ins. wide.

The normal speed of each 5 ton vehicle is 25 miles per hour, whilst -maximum speeds, under full load and on the level ot 45 m.p.h. have been attained.

It will now be seen (1) that the tandem axles are brought as close together as is' practicable, (2) that the axles can rise and fall independently of each -other, and that there is ample flexibility in the axle assembly, permitting the wheels to follow any ground inequality without disturbing themechanism ; (3) that there is no differential betwen the forward and rearmost driving axles, and (4) that the forward driving wheels are not called upon to take part in the steering of the vehicle.

Now, if a steering diagram for any vehicle, whether it has four or any greater number of wheels, be struck, it will be found (-1) that the radius of the curve described by the wheels on the rearmost axle is less than that of the curve described by the wheels on the foremost axle; (2) that the nearer a middle axle be to the front axle the greater the angle of its wheels must be in relation to the centre line of the vehicle, or, per contra, (3) that the nearer the middle axle be to the rearmost axle the less will be the angle of its wheels. Again, if any pair of wheels be in advance of any other pair, the former pair will, when the vehicle is travel. ling in a curve, travel a longer distance than is travelled by the rearmost pair.

The Goodyear Co. took up this point, which was referred to in theissue of The Commercial Motor for

June 7th last, and answers the criticism with a set of photographs showing the marks of the wheels of a six-wheeled van on a sandy surface. The vehicle was run round in a complete circle, the raclius of the track of the outer front wheels being 31 ft. 4 ins., and that ofthe track of the outer rear wheel 27 ft. 5 ins.

These circles were then laid out in a diagram, and the skeleton of the vehicle superimposed upon the The distance between the heavy line drawn at right angles to the face of the rim and the broken line through the centre of the tyre shows how the tyre by warping sideways will accommodate itself to the matalignment of the tandem axle driving wheels when turning in a

tracks. The axles being closer together than we had calculated when our article in the issue or June 7th was written it was found that the rear wheels did not theoretically fit the actual track, but would follow, two different tracks which were only three-quarters of an inch apart, an amount that is -really extremely sniall and would not involve very much slip or appreciable tyre wear. Even this small difference is accounted for in the case of a pneumatic tyre, but it could not be so disposed of in the case of solid tyres, and there the ill-effects of the slip, albeit small, would be observable. In the case of the Goodyear chassis, the diagram shows that the tyres of the wheels of the forward driving axle will deform or warp, sideways and outwards by about three-eighths of an inch, whilst those on the rearmost driving axle Will deform inwards to the same extent. The.amaunt of deformation (due to the inal-alignment of the wheels to the,-extent, as we make it, of approximately five degrees) is so small that it is claimed that no ill results could occur. If one had the _slightest doubt on this SCOT e let him call an empty taxi driving in the opposite direction to which one wants to travel and then watch the front wheels and tyres as the driver turns in a circle of 12 ft. radios (as the London taxi always does). The side deflection of the tyre will look dreadful, being considerably more than the three-eighths of an inch disclosed in the case of the test with the six-wheeler.

The small -difference in the mean turning radii of the two driving axles and the deflection outwards of the foremost tyres and inwards of the rearmost tyres also permit the differential between the two axles to be dispensed with, and this at once brings in a decided advantage of which we have already made mention in these columns.

Dispensing with the Inter-axle 'Differential.

If the power to the two wheels on an axle is trans-. milted through a differential gear, the engine is enabled to accelerate when one of the wheels leaves the ground, and the speed of rotation of that wheel will then also be accelerated. When the tyre again touches the ground it will be rotating faster than when it left it, and the sudden retardation of the speed can only be effected by an abrasion of the tyre. It has been proved in racing (when the wheels are not in contact with the ground for an appreciable total proportion of the time) that it is better in the long inn to dispense with the differential.

Now., with four wheels driven off one shaft and with differentials only between the wheels on the same axle, all wheel spinning is entirely prevented,

• except in the unlikely circumstance of one wheel on one axle and one wheel on the other axle being simultaneously off the ground. In all eases where only one wheel is out of contact with the ground, it cannot accelerate in rotational syeed whilst in the air, but must again strike the ground at an unaceelerated speed and without abrading the tyre. Thus, there is a distinct advantage in regard to tyre weer when travelling in a straight line over rough roads, gained by the elimination of the interaxle differential, and this may compensate for the small amount of sideslip due to the central wheels not steering when turning out of the straight. As proof of the small amount of wear imposed upon the tyres of six-wheeled 5 ton vehicles, we give the following tyre record of the six machines built and operated by the company, the figures being taken about a month ago.

Five-tonner number — had operated

1 12,000 miles

2 10,000 „ 2 22,600 „ 4 10,400 „ 5 5,000

6 Testing Thus, with these vehicles alone a total distance of upwards of 60,000 miles had been covered with extremely few tyre replacements, 14,000 miles being well within the life of a large pneumatic.

Six Wheeler Saving in Running Costs.

Another curious fact came to light on an examination of the operating costs, for it was discovered at the completion of 40,000 miles' experience that the cost of operatinx the 5 ton six-wheeler approximated very closely to the similar cast of the standard 3-i ton vehicles that had been run by the company.

These facts are extremely important, because there is far more to be gained or lost in running costs and maintenance charges than in capital charges. Thus the fleet manager or owner of but a single vehicle should choose the type which is most economical in those items of expenditure.

Readers of The Commercial Motor will be familiar with the six-wheeled motor coach which was built by the Goodyear Co. for the conveyance of their workpeople between the works and the residential centre at Akron. It was put into service in the summer of last year, and it has proved of great benefit to the workers and has relieved the traffic on the publicservice vehicles. It is designed to seat 44, but in rush-hour service it often carries from 80 to 100.

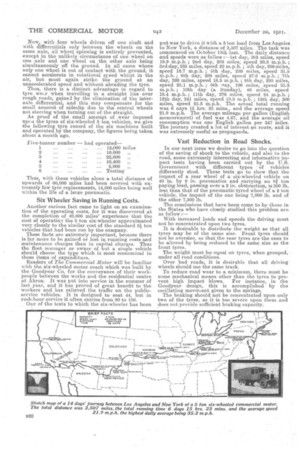

One of the tests to which the six-wheeler has been

put was to drive it with a 5 ton load from Los Angeles to New York, a distance of 3,507 miles. The task was commenced on October 13th last. The daily distance and speeds were as follow :-1st day, 393 miles, speed 19.9 m.p.h. ; 2nd day, 293 miles, speed 20.9 m.p.h. ; 3rd Vast Reduction in Road Shocks. In our next issue we desire to go into the question of the saving of shock to the vehicle, and also to the road, some extremely interesting and informative impact tests having been carried out by the U.S. Government with different types • of vehicles differently shod. These tests go to show that the impact of a rear wheel of a six-wheeled vehicle on 40 in. by 8 in. pneumatics and carrying an 81 ton paying load, passing over a 2 in. obstruction, is 300 lb. less than that of the pneumatic-tyred wheel of a 2 ton vehicle, the impact of the one being 7,000 lb. and of the other 7,300 lb. The conclusions that have been come to by those in the States who have closely studied this problem are as follow :— With increased loads and speeds the driving must not be concentrated upon two tyres. It is desirable to distribute the weight so that all tyres may be of the same size. Front tyres should not be oversize, so that the rear tyres are the ones to be altered by being reduced to the smile size as the front tyres. The weight must be equal on tyres, when grouped, under all road conditions. Over bad roads, it is desirable that all driving wheels should use the same track. To reduce road wear to a minimum, there must be some mechanical means other than the tyres to prevent high impact blows. For instance, in the Goodyear design, this is accomplished by the oscillating movement given to the springs. The braking should not be concentrated upon only two of the tyres, as it is too severe upon them and does not provide sufficient braking capacity.Tags