FULL WEIGHT OF THE LAW

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

At long last the DTP has issued new Special Types regulations. Some manufacturers will like them — some operators won't. We assess the changes they will cause.

• Over three years' uncertainty for heavy haulage operators ended on 6 August with the publication of the Department of Transport's new Special Types General Order regulations. They are intended to bring the UK more into line with continental requirements for the movement of what the DTp continues to define as "abnormal indivisible loads".

Statutory Instrturient 1327 sets out details of the STGO authorisation procedure, while S1-1326 details the markings (plating) of tractors and trailers to their indicated permitted axle loads and speeds.

It has been the legislators' aim to make Special Types 'less special' by bringing them closer to the normal Construction and Use Regulations which cover vehicles up to 38-tonnes GCW.

POTENTIAL DAMAGE

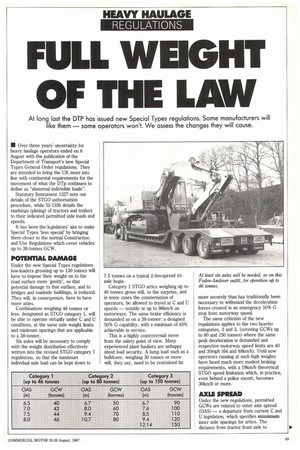

Under the new Special Types regulations low-loaders grossing up to 150 tonnes will have to impose their weight on to the road surface more 'gently', so that potential damage to that surface, and to bridges and roadside buildings, is reduced. They will, in consequence, have to have more axles.

Combinations weighing 46 tonnes or less, designated as STGO category I, will be able to operate virtually under C and U conditions, at the same axle weight limits and minimum spacings that are applicable to a 38-tonner.

Six axles will be necessary to comply with the weight distribution effectively written into the revised STGO category 1 regulations, so that the maximum individual axle load can be kept down to 7.5 tonnes on a typical 2.6m-spread triaxle bogie.

Category 1 STGO artics weighing up to 46 tonnes gross wilt to the surprise, and in some cases the consternation of operators, be allowed to travel at C and U speeds — notably at up to 961trigh on motorways. The same brake efficiency is demanded as on a 38-tonner: a designed 50% G capability, with a minimum of 45% achievable in service.

This is a highly controversial move from the safety point of view. Many experienced plant hauliers are unhappy about load security. A lump load such as a bulldozer, weighing 30 tonnes or more will, they say, need to be restrained far more securely than has traditionally been necessary to withstand the deceleration forces created in an emergency 50% G stop from motorway speed.

The same criticism of the new regulations applies to the two heavier categories, 2 and 3, (covering GCWs up to 80 and 150 tonnes) where the same peak deceleration is demanded and respective motorway speed limits are 40 and 30mph (64 and 481(m/h). Until now operators running at such high weights have faced much more modest braking requirements, with a 191(m/h theoretical STGO speed limitation which, in practice, even behind a police escort, becomes 30km/h or more.

AXLE SPREAD

Under the new regulations, permitted GCWs are related to outer axle spread (OAS) — a departure from current C and U legislation, which specifies minimum inner axle spacings for artics. The distance from tractor front axle to

rearmost semi-trailer bogie axle effectively limits maximum GCW to graduated levels in each of the three categories above 38 tonnes.

Axle loadings allowed on low-loaders built to run at more than 46 tonnes (in categories 2 and 3) are likely to cause problems for many current STGO operators. In category 2 users face a reduction in axle weights on bogies, typically from 14 to 12.5 tonnes, necessitating additional axles to carry the same load, though a number of tri-axle low-loaders have already been built by manufacturers like Andover Trailers in anticipation of the new legislation.

SPEED LIMIT

Tied in with the changes to axle weights and the related speed limit concessions is a new legal requirement on tyre ratings. The tyre makers' load/speed markings, already familiar within a C and U context, now become relevant to special types operation as well.

One of...the biggest surprises in the new STGO regulations is the rapidity with which they are to be implemented. They come into force on 1 January 1988 — in other words operators have barely four months to get their trailers and/or tractor units modified if they need to in order to comply with the new axle weight limits. As manufacturers are interpreting the rules, they have until October 1989 before new trailers going into service must comply with them.

Modifications necessary to current combinations will vary a lot.

Axle loadings and approved tyre ratings will, in many instances, call for an increase in the number of axles.

Enforcement of axle weight limits on special types heavies is expected to be tightened under the new legislation, with minimal tolerance by the authorities of overloads, caused for example by poor balance-beam compensation between leaf springs on adjacent axles. Air or (on the heaviest category 3 vehicles) hydraulic suspension as a sure means of equalising bogie loads across all axles is expected to become almost universal.

Conversion of existing tandem bogies to tri-axle configuration for category 1 STGO working, will be theoretically possible, although the practical considerations are likely to sway many users towards complete replacement.

It is hardly surprising that low-loader manufacturers like King, Andover and Trailmaster have welcomed the publication of the new laws with relief, even glee. They see the removal of the uncertainty as a green light to operators to implement long overdue fleet renewal programmes.

HEAVY EXPENDITURE

Plant hauliers and machinery carriers have far less reason for euphoria. They face heavy expenditure in having their tractors and trailers either modified or replaced. Adding a Granning type (non-steered) centre axle to a 4x2 tractor to enable it, as a 6x2, to accept heavier king-pin loads (say up to 14 tonnes in category 1) without the trailer neck needing to be extended, could cost at least £4,000.

Turning a tandem bogie into a tri-axle could prove a major job. Existing fourspring or centre-pivot tandems do not lend themselves to easy conversion. An add-on axle with air springs, if it is to

maintain its correct 33% share of the bogie load, needs to be fed with pressure via a load-sensing valve monitoring spring deflection on one or both remaining axles. On most low-loaders spring movement is so small as not to be usable in this way.

Drop-deck low-loaders with a raised bridge above the bogie present a further headache for would-be 'axle adding' converters. An increase in bridge length is implied. Few if any operators will want to sacrifice main (lower) deckspace, so a rearward extension becomes necessary — making the trailer a metre or more longer. This might not matter legally for wholly STGO operation, but in engineering terms it results in a lot of additional bending stress being imposed through the structure, so welded strengthening straps may become necessary.

Some heavy hauliers regard the STGO law changes with real dismay. They cite the absence of related load retention rules as a reason for thinking that the 1988 law will have to be amended. In the view of the managing director of one of Britain's biggest heavy haulage concerns, "That would be the thin end of the wedge. The DTp would take the opportunity to make other changes. What we are looking for is a period of eight to 10 years of stability."

He points out that plant trailers are expensive, heavy-duty pieces of equipment with a life expectation of at least a decade. Operators need to be confident, he says, that today's capital expenditure is money spent wisely and with due foresight.

0 by Alan Bunting