Tough decisions face small operators assessing deman1 trends and specifying bodywork and equipment whe

Page 31

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

ordering new trucks by Paul Brockingtc

THE SMALL operator who is into refrigerated or insulated haulage faces a difficult problem when looking for his best buy in bodywork and equipment.

Its not easy even for leading operators of heavier trucks, engaged on Continental as well as domestic traffic. There are so many questions, so many imponderables. Typically, they run vehicles which are -overspecifiedfor average conditions. Then they can cope with longer runs in hotter climes and have spare capacity in hand.

This is something the operator covering shorter distances on domestic routes must view with caution. It's difficult to advise him to overspecify to cater for possible changes in demand and/or prospective regulations. Talking to a repu

table bodybuilder should be an .early step in future planning.

Advice might include the use of more costly insulant and refrigerating equipment of higher capacity than is needed for current work But it could be a sound investment. He must take into account that the average claimed life of, say, bodies from Silverdale Refrigerated Vehicles Ltd, of Hall Green, Birmingham, is upwards of 10 years. Anything could happen in that time, including an increase in cost of at least 135 per cent.

The problem how to regularize the carriage of foodstuffs to the benefit of the producer, the carrier, the vendor and the consumer is universal. A lot of produce is being carried in non-insulated vehicles at excessively high temperatures or in insulated/refrigerated trucks at an unsuitable temperature despite the increasing insistence of cold-store companies that produce be transported at a stipulated temperature.

A spy-in-the-van instrument is sometimes used to record changes of temperature against time during a delivery run. I can only hope this is a sign of a progressive development which will make for improved food quality in the market place, whether or not it is influenced by the EEC or by ATP.

Would a refrigerating system that controlled temperature to within one degree F of a predetermined limit not be a great help to operators? The Shipowners' Refrigerated Cargo Research Association of Cambridge has developed one for its industry. This is the sort of question still awaiting a generally agreed answer. addition to France, West Germany and Spain.

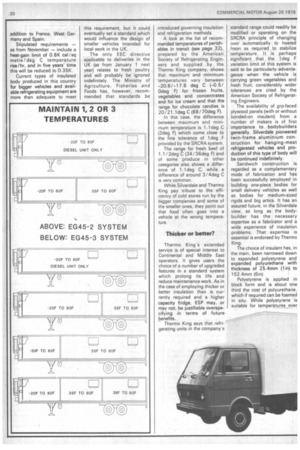

Stipulated requirements — as from November — include a heat-gain limit of 0.6K cal/sq metre/deg C temperature rise/hr, and in five years' time this will be reduced to 0.35K.

Current types of insulated body produced in this country for bigger vehicles and available refrigerating equipment are more than adequate to meet this requirement, but it could eventually set a standard which would influence the design of smaller vehicles intended for local work in the UK.

The only EEC directive applicable to deliveries in the UK (as from January 1 next year) relates to fresh poultry and will probably be ignored indefinitely. The Ministry of Agriculture, Fisheries and Foods has, however, recommended that standards be introduced governing insulation and refrigeration methods.

A look at the list of recommended temperatures of perishables in transit (see page 32), prepared by the American Society of Refrigerating Engineers and supplied by the Thermo King company, shows that maximum and minimum temperatures vary between -20.6/-17.8 deg C (-0.5/ Odeg F) for frozen fruits, vegetables and concentrates and for ice cream and that the range for chocolate candies is 20/21.1deg C (68 / 70deg F).

In this case, the difference between maximum and minimum temperature is 1.1 deg C (2deg F) which come close to the fine tolerance of ldeg F provided by the SRCRA system.

The range for fresh beef of 1.1 /2deg C (34 /36deg F) and of some produce in other categories also shows a difference of 1.1deg C, while a difference of around 3 /4deg C is very common.

While Silverdale and Thermo King pay tribute to the efficiency of cold stores run by the bigger companies and some of the smaller ones, they point out that food often goes into a vehicle at the wrong temperature.

Thicker or better?

Thermo King's extended service is of special interest to Continental and Middle East operators. It gives users the choice of a number of upgraded features in a standard system which prolong its life and reduce maintenance work. As in the case of employing thicker or better insulation than is currently required and a higher capacity fridge. ESP may, or may not, be justifiable overspecifying in terms of future benefits.

Thermo King says that refrigerating units in the company's

.standard range could readily be modified or operating on the SRCRA principle of changing over automatically to heated freon as required to stabilize temperature. It is perhaps significant that the 1deg F variation limit of this system is said to be particularly advantageous when the vehicle is carrying green vegetables and fresh fruit; considerably wider tolerances are cited by the American Society of Refrigerating Engineers.

The availability of grp-faced plywood panels (with or without bonded-on insulant) from a number of makers is of first importance to bodybuilders 'generally. Silverdale pioneered twin-frame aluminium construction for hanging-meat refrigerated vehicles and production of this type of body will be continued indefinitely.

Sandwich construction is regarded as a complementary mode of fabrication and has been successfully employed in building one-piece bodies for small delivery vehicles as well as bodies for medium-sized rigids and big artics. It has an assured future, in the Silverdale view, so long as the bodybuilder has the necessary expertise as a fabricator and a wide experience of insulation problems. That expertise is essential is endorsed by Thermo King.

The choice of insulant has, in the main, been narrowed down to expanded polystyrene and expanded polyurethane with thickness of 25.4mm (1n) to 152.4mm (6in).

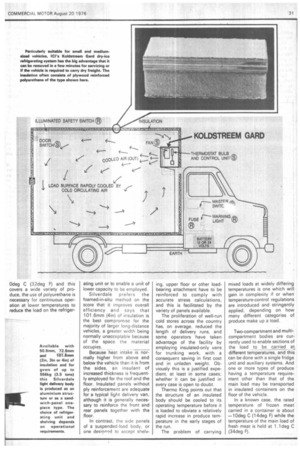

Polystyrene is applied in block form and is about one third the cost of polyurethane, which if required can be foamed in situ. While polystyrene is suitable for temperatures over

Odeg C (32deg F) and this covers a wide variety of produce, the use of polyurethane is necessary for continuous operation at Lower temperatures to reduce the load on the refriger

ating unit or to enable a unit of lower capacity to be employed.

Silverdale prefers the foamed-in-situ method on the score that it improves overall efficiency and says that 101.6mm (4in) of insulation is the best compromise for the majority of larger long-distance vehicles, a greater width being normally unacceptable because of the space the material occupies.

Because heat intake is normally higher from above and below the vehicle than it is from the sides, an insulant of increased thickness is frequently employed for the roof and the floor. Insulated panels without ply reinforcement are adequate for a typical light delivery van, although it is generally necessary to reinforce the front and rear panels together with the floor.

In contrast, the side panels of a suspended-load body, or one desiened to accept shelv

ing, upper floor or other loadbearing attachment have to be reinforced to comply with accurate stress calculations, and this is facilitated by the variety of panels available.

The proliferation of well-run cold stores across the country has, on average, reduced the length of delivery runs, and some operators have taken advantage of the facility by employing insulated-only vans for trunking work, with a consequent saving in first cost and in unladen weight. Obviously this is a justified expedient, at least in some cases; whether it can be justified in every case is open to doubt.

Thermo King points out that the structure of an insulated body should be cooled to its operating temperature before it is loaded to obviate a relatively rapid increase in produce temperature in the early stages of the run.

The problem of carrying mixed loads at widely differing temperatures is one which will gain in complexity if or when temperature-control regulations are introduced and stringently applied, depending on how many different categories of produce make up a load.

Two-compartment and multicompartment bodies are currently used to enable sections of the load to be carried at different temperatures, and this can be done with a single fridge unit and auxiliary systems. And one or more types of produce having a temperature requirement other than that of the main load may be transported in insulated containers on the floor of the vehicle.

In a known case, the rated temperature of frozen meat" carried in a container is about —10deg C (14deg F) while the temperature of the main load of fresh meat is held at 1.1deg C (34deg F).