WARMING THI

Page 26

Page 27

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

WORKSHO

A review of space heaters

IF common humanity and regard for employees does not prompt the employment of efficient heating for workshop and depot staff in winter, then self-interest should be influenced by the fact that men will not work so well when they are cold and miserable. There are also legal requirements to consider.

Although one or two companies still offer solid-fuel stoves, the vast majority of industrial space heating systems these days are radiant, convection or warm-air units burning oil, gas or electricity. There is a wide choice of types as well as of fuels—for many applications in the transport field the free-blowing warm-air system has advantages, and wheeled versions have the merit that they can be taken to the job, which may sometimes be a vehicle stranded in the yard. It may also be appropriate to have a ducted system, for instance to carry warm air between storage racks and vehicles. At doorways a warm air curtain kills all draughts but is liable to suffer considerable heat losses. Rubber swing doors are a way round this.

Among fuels, gas is now becoming very competitive with oil; running costs are fairly similar, and whereas gas may sometimes appear more expensive to run, large users can get a preferential tariff. Where offices adjoin workshops and have to share a common heating system it may still prove better to use a hot-water radiator system than direct hot air.

Certain installations are governed by very strict regulations. For example, a spray-booth area must have fresh air, not recirculated, in any system of heating and ventilation, and any direct heating must be by radiation and not convection. In areas where fuel vapours may be lying close to the floor, there will be a minimum recommended level for the air intake of space heaters. In any combustion installation there must be provision for removing the products of burning: most modern package units simply require a vent to atmosphere. Where air is used for combustion only, it must come from outside.

Where old buildings are being equipped with heating a radiator system is usually cheaper to install than air—pipes can be run more easily through walls etc than ducts.

Heat loss is a factor to be considered. Some heat loss may be direct—for example, it is wise to isolate spray booth areas completely from the rest of the workshop, otherwise the constant intake of fresh (cold) air and its constant return (heated) to atmosphere at a particularly high rate of air change per minute can make it very difficult to maintain good temperatures in the rest of the building.

The heat loss is measured by a coefficient /4 and typical figures are glass 1.0, asbestos 1.4, 9in. brick 0.45 and typical concrete floor 0.2. Perhaps surprisingly, a heating specialist tells us that corrugated asbestos has the worst heat-loss characteristics of all normal roof claddings. All insulation can be very expensive, but a false ceiling can be a satisfactory method so long as it does not interfere with lighting; double glazing is worth considering—preferably with expert advice. Local by-laws cover several aspects of heating buildings, for example the siting of fuel storage tanks. Also, use of sump oil in burners (which is not recommended by some manufacturers) might cause an operator to fall foul of the Clean Air Acts. The Offices, Shops and Railway Premises Act lays down that in offices, for instance, there should be an air change of 1000cu.ft of air per person per hour, but the figure for factories and workshops varies according to the use. Similarly, the Act stipulates that a temperature of at least 60.8deg F must be obtained in an office within one hour, and that 68.5deg F must be maintained as a normal air temperature. For industrial premises there is no such precise ruling, but the general basis is 65deg F.

Deciding how much heat is needed in a particular instance is a job for a specialist, but a rule-of-thumb guide suggests that if you calculate the cubic capacity in ft of the space to be heated and multiply by 5 you will get a rough estimate of the Btu /hr needed. So a workshop 50ft long by 30ft wide and 15ft high will need rather more than 110,000 Btu /hr. Where roof insulation is good and there are no big loss areas (eg open doors) the volume in cu ft may be multiplied by 3 or 4.

Two authorities should always be consulted when installing heating in an existing building—the local council to check on by-laws, and your insurance company to ensure that policies are not affected. It is also wise to ask the local fire prevention officer to cast an eye over your plans. Where new buildings are going up, the heating should be dealt with professionally by architect or builder—and the insurers will no doubt receive details of heating along with other specifications when they are invited to cover the building.

The following companies have responded to our invitation to provide details of their space heating products. In many cases the units have automatic shut-down or overload cut-out switches, but when contemplating purchase of any heating device it is wise to inquire about safety measures.

ALLCHIN

E. F. Alichin & Co Ltd, Efaco House, 45 Green Lane, Birmingham 9.

A WASTE oil burning workshop heater is featured in the Allchin range of space heaters; heat output of the various units ranges between 20,000 and 100,000 Btu per hr.

Operated on any heating fuel oil, the model H50 has a fully adjustable heat range from 20.000 to 100,000 Btu per hr and can be made to run for 12-13hr on just one filling. Fuel consumption is given as approximately 0.5 gph.

Price is £56 ex-works..

DRAGONAIR

Dragonair Ltd, Fitzherbert Road Faith:gram Portsmouth.

GASand oil-fired warm air heaters are manufactured and installed by this company in units from 150,000 to 1,000,000 Btu/hr. Consumption of the oil heaters is from 1.2 to 7.6gph from smallest to largest output.

The units can be mounted vertically or horizontally and can be used for free-blowing installations or for ducted systems.

HAINAULT

Hainault Engineering Co Ltd, 216 Fowler Reed, Hainault, Ilford, Essex.

A WIDE range of both oil-fired and gas fired floor-standing and suspended heaters is listed by Hainault. Heat outputs of the oil-fired heaters vary between 100,000 and 1,500.000 Btu/fir and the gas fired heaters 150,000 to 1,500,000. Oil consumption varies according to output, between 0.67 and 7.72 gat per hr and gas consumption is between 1.1 and 10.5 therms per hr. Prices range from £240 for a 100,000 Btu floor-standing oil heater to £1620 for a 1,500,000 Btu pressure gas type.

HARRIS

Harris Engineering Ltd, Longfield Read, Tunbridge Wells, Kent.

GAS infra-red radiant heaters said to be ideal for heating problem buildings, such as buildings poorly insulated, are featured in addition to other gas and oil-fired air heaters in the Harris range. Heat outputs of both gas and oil-fired heaters range between 200,000 and 800,000 Btu/hr; these heaters are available as horizontally suspended, free standing or external models.

Further to these are gas-fired unit heaters and gas-fired radiant heaters with capacities of 66,000-140,000 Btu/hr and 12.500-75,000 Btu/hr respectively. Gasfired air heating systems are claimed to give particularly low running costs.

HECTA

Landmaster Ltd, Hucknall, Notts.

TWO versions of the Hecta 105D space heater are marketed by Landmaster, both running on paraffin or light gas oil. They are the "standard" and the "super" models, both possessing heat capacities of 105.000 Btu per hr, but the super model being fitted with a safety flame-failure device. Both are wheel-mounted mobile heaters which blow hot air. Prices are £123 and £140.

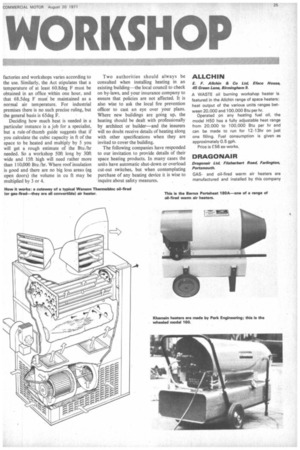

KHAMSIN

Park Engineering (Paddock Wood) Ltd, Agroup House, 76 Lansdale Gardens, Tunbridge Wells, Kent.

MARKETED under the name of Khamsin these space heaters fall into four categories, namely: manual control, capacities 125,000340.000 Btu/hr; Autocontrol models: suspended models: and static models. The latter three categories are developments of the standard manual-control models. Fuel consumption for the manual control models is up to 2.125 gal per hour for the largest and the volume of warm air produced varies between 525 and 3000 cfm.

Prices: from £115 for a 125,000 Btu oil-burning heater to around £220 for large suspended or Autocontrol models.

PORTAH EAT

E. P. Barrus (Concessionaires) Ltd, 12-16 Brunel Road, Acton, London W3.

SUFFICIENT heat for buildings between 15,000 and 16,000 cu.ft, is said to be emitted from the Barrus range of portable heaters. Outputs from the heaters vary from 90,000 to 320,000 Btu/hr and two of the models are available as thermoautomatic heaters. Models 180 080.000 Btu/hr) and 320 1320.000) in both standard and thermo-automatic form can be used as suspended heaters with remote tanks. hour for the 90,000 Btu model.

Prices of these Portaheat models range from £107 to £227.

STENOR

Stenor Ltd, Lyon Industrial Estate, Mortlake Road, Kew, Richmond, Surrey.

THREE basic models are now available from Stenor, types 50, 100 and 105 MK II. (The model 175 is now discontinued). All three use paraffin (kerosene). Heat output is 50,000. 100,000 and 105,000 Btu/hr respectively.

The 105 can be produced as a tankless version for connecting to bulk fuel supplies. thus giving continuous 500 cfm without constant attention. Models 50 and 100 have air capacities of 250 cfm and 450 cfm respectively with claimed average fuel consumptions of between 0.3 and 0.63 gal per hour.

THOMAS

Lionel Coup and Co Ltd, 164 High Street, Birmingham 12.

THE brand-name of Thomas is used for the solid-fuel space heaters made by this company in two main models—the Senior to heat spaces of 60,000 cu.ft. and the Junior for approximately half that volume.

They are tall multi-unit stoves made up from quickly assembled sections, and have a top flue. Basic prices are £40 and £50 for the two models, and coke consumption is said to be 4/8Ib per hr for the smaller and 5/9 for the larger.

TROPICAL

Boscombe Engineering Ltd, Tropical Works, 145 Sterte Road, Poole, Dorset.

TEN Tropical oil-fired heaters designed particularly for garage and service station applications are available from Boscombe Engineering. Four are direct-fired portable units giving heat outputs of 50,000 to 300,000 Btu/hr. Two other vented models give heat outputs of 160,000 and 300,000 Btu. Suspended versions of two of the portable models are available and these are for use in fixed installations with remotely sited fuel tanks. All the heaters but two operate with high-pressure fuel; the low pressure fuel heaters only being available with automatic operation.

WAN SON

Wanson Co Ltd, 7 Elstree Way, Boreharn Wood, Herts.

THIS company makes and installs Thermobloc Multipass warm air heating equipment, using units designed to operate either on gas or oil. They range in heat output from 150,000 to 3,500,000 Btu/hr and can be used for free-blowing or ducted installation, for vertical or horizontal mounting and for recirculation or the blowing of fresh air. They can be used to provide warm-air curtains and have been employed in spray booths where air must be fresh and not recirculated.

A new item is a Gasairbloc door heater which provides high-volume warm air at doorways; the standard output is 700,000 Btu/hr.