ARE OVERHEAD VALVES WOI I THE ADDED COMPLICATION I

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

In All Essenti Road-vehicle Leave Little Over ements of the Side Valves ired, so Why .'es 2

ONE of the /host, frequent demands made upon the engine designer is for overhead valve, which are . generally believed to increase the output of an engine to a degree only equalled by the addition of several cylinders. The fact that little accurate data of a type sufficient to assess values are ever published by manufacturers seems to have had little effect in modifying such an impression. Because.overhead-valve engines are used in.racing cars that would appear to be ample justification for their use in other spheres of operation.

Sufficient interest is rarely forthcoming, even in technital circles, to conduct tests on engines, each designed to give optimum performance, with both types of valve gear, with a view to assessing their 'relative worth. It is to be admitted that, in many cases, the technical departments are subject to financial and sales influences, but the root cause lies in public demand. • Even the actual types of overhead gear and their respective merits are inclined to be gauged' only on their success or Otherwise when employed in racing engines. It is intended, therefore, to investigate the advantages and disadvantages of the various arrangements, and to quote some actual figures in an attempt to compare their potentialities, although any such endeavour can be, at best, merely empirical owing to the lack of complete data.

The primara need of the average commercial-vehicle operator is a power unit which will produce the greatest amount of energy for a minimum expenditure in fuel cost. Moreover, he wants to incur the lowest outlay in first cost and maintenance, when considered over the lifetime of the vehicle.

To fulfil the requirements of road service, an engine must have a high torque capacity at normal operating speeds, whereas a high-power output at high engine speeds is not of any great importance. Stress will not, therefore, be laid on engine performance at high r.p.m. so muchas at an average speed, a fact which must be borne in mind.

High Compression Essential to Efficient Operation , To ensure the most economical burning of a fuel, a high compression is necessary, and an engine ;which will run smoothly under such conditions is, obviously, to be desired. Compression shoula not be tonfused with compression ratio, which is frequently incorrectly used in this sense. Compression ratio is the ratio exissting between the swept cylinder volume and the combustion chamber space, and although, at low speeds, little exception may be taken to the loose terminology, at high speeds the mixture drawn into the cylinder becomes considerably less than the swept volume and the compression pressure decreases.

Obviously, this reduction of volumetric efficiency reacts unfavourably on the performance of an engine, for the power output in a giv'en unit depends on the quantity of fuel burned on each power stroke. It is in an attempt to reduce. the factors which tend to lower volumetric efficiency that overhead valves prove their _true value, and, for high-speed engines of the sports type, they are essential to the maintenance of power at high r.p.m. However, high engine revs, are a luxury which the commercial-vehicle operator cannot-afford, and, 'what is more, the need is not apparent.

The o.h.v. engine has, undoubtedly, the advantage that the induction and exhaust ports rday be designed t afford an almost straight path for the gases, thereby seducing the resistance to gas flow which, furthermore, is travelling in the same direction as the piston.

In the side-valve design, the gas flow must, necessarily, be rather more tortuous as it must first pass upward through the valve port, and then down into the cylinder. Although this condition must, .to a certain extent,'exist in any design of side-valve unit, this untoward influence may be minimized to a surprising degree in the drawing-board stage. • In an effort to produce a compact unit, volumetric efficiency may be adversely affected by making the cylinder head shroud the valve too closely, whilst similar results 'follow the raising of the inlet port in relation to the top face, of the cylinder block. The close proximity of the cylinderhead to the port constricts the outlet around the valve, so that full advantage cannot be taken of the aperture.

A similar effect is produced by the 'high port, as the rapidly flowing mixture tends to travel as nearly straight as possible. The consequence of this is that the bias of flow is through onlya part of the valve-port area, the result being similar to the physical shrouding already explained.

Correct practice is to lead the mixture into a path as nearly axial with the valve stem as is possible, thus straightening the flow in the port before it is admitted , by the valve. 'Generous clearance around the valve head is imperative. With good design, the flow characteristics of a side-valve engine may be made cornparable with those obtained with overhead valves, even up to a peak of 5,000

As explained in a previous article, the size -of the cylinders influences the type. of valve gear that is to be used, • and a large 'combustion .chamber naturally increases the distance over which the flame has to travel. In an L-headed

side-valve engine this is at a maximum, so that, in the case of large-capacity cylinders, overhead valives become almost a necessity.

• When an engine builder produces both petrol and oil types it may 'be more economical to design the Major components to be interchangeable; side valves have not been found practicable for compression-ignition engines.

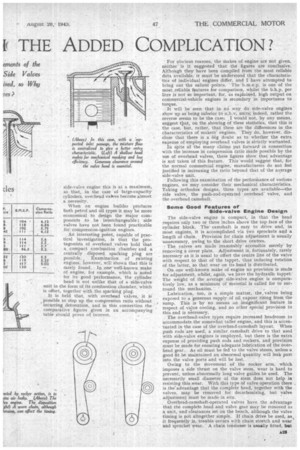

. An interesting point, capable of practical investigation, is that the pro

tagonists of overhead :valves hold that a._ compact combustion chariTher and a

centrally disposed sparking plug are possible, " Examination of existing engines, however; will shown that this is rarely found.. In one well-known make of engine, for example, which is noted for its good performance, the cylinder head is not unlike that of a side-valve unit in the form of its combustion chamber, which is offset, together with the sparking plug.

It is held that, with overhead Valves, it iS possible to step up the compression ratio without incurring detonation, and in this connection the comparative -figures given in an accompanying table should prove of interest.

For obvious reasons, the makes of engine are not given, neither is it suggested that the figures are conclusive. AlthoUgh they have been compiled frOm the most reliable data available, it must be understood that the characteristics of individual engines differ, and I have attempted to bring out the salient points. • The b.m.e.p.• is one of the most,reliable features for comparison, whilst the b.h.p. per litre is not So important, for, as explained, high output on commercial-vehicle engines is secondary in importance to torque. It will be seen that in no way do side-valve engines show up as being inferior to o.b.v. units; indeed, rather the reverse seems to be the case. _I would not, by any means, suggest tat, on the showing.of these statistics, that this is the case, but, rather, that these are the differences in the. characteristics of makers' engines. They do, however, disclose that there is a big doubt as to whether the extra expense of employing overhead valves is strictly warranted. In spite of the manyclaims put forward in connection with the increase in compression ratio Made possible by the use of overhead valves, these figures show that advantage is not taken of this feature. This would suggest that, for the norrnal.commercial engine, manufacturers do not feel justified in increasing the ratio beyond that of-the average side-valve unit.

Following this examination of the performance of various • engines, we may consider their mechanical characteristics. Taking Orthodox designs, three types. are available—the Side valve, the push-rod-operated overhead' valve, and the overhead camshaft.

Some Good Features .

Side-valve Engine Design The side-valve engine is compact, in that the head requires only two or three inches above the top face of the cylinder block. The camshaft is easy to drive and, in most engines, it is accomplished via two sprockets and a length of chain. Provision for chain adjustment is usually unnecessary, wing to the short drive centres.

• The, valves -are made reasonably accessible merely by removing a cover plate. Adjustment is, fortunately, rarely necessary as it is usual to offset the centre line of the valve with respect to that of the tappet, thus inducing rotation of the latter, so that wear on its head is distributed.

On. one well-known make of engine no provision is made for adjustment, whilst, again, we have the hydraulic tappet.' The weight of the average side-valve engine is comparatively low, as a minimum of material is called for to Surround the mechaniSm.-.

Lubrication, too, is a simple matter, the_valves being exposed to a "generous supply of oil vapour rising from the sump. This is by no means an insignificant feature in respect of valve cooling, -and no other special provision to this end is necessary..

The overhead-valve types require increased headroom to accommodate the somewhat taller engine, and this is accentuated in the case of the overhead-camshaft layout. When push rods are used, a similar camshaft drive to that used with side-valve engines is employed, but there is the extra expense of providing push rods and rockers, and provision must be made for ensuring adequate lubrication of the overhead gear. As oil must be fed to the'valve stems, unless a good fit be maintained an abnormal quantity will leak past into. the valve ports and will be lost.

Owing . to the movement of the rocker arm, which imposes a side thrust on the valve stem, wear is hard to prevent, unless abnormally long valve guides be used. The necessarily small diameter of the stem does not heIp• in resisting this wear. With this type Of valve operation there , is the advantage that the complete head, together with the valves, may be removed for de.carbonizing, but valve adjustment must be made in situ.

Overhead-camshaft-operated valves 'have the advantage that the complete head and valve gear may be removed as a unit, and clearances set on the bench, although the valve timing is pot altogether simple.. If chain driVe be used, as it frequently is,trouble.occurs with chain stretch and wear and sprocket -wear. A chain tension is usually fitted, but

this does not altogether cure the trouble. As this is fitted on only the slack side of the chain. the progressiVe take up of the slack rotates the camshaft with respect to the crankshaft, thus affecting the valve timing. To remedy this, a means thr effecting a fine adjustment must be incorporated.

If the cams work directly on to the valve stetas, side thrust occurs, and this is not entirely eliminated even if rocker arms be interposed. Here, again, lubrication is not easy, and in many engines a separate pump is used to lubricate the valve gear. Drives for auxiliaries are not easy to incorporate, and extra gearing or sprockets are needed. • The maintenance of the correct adjustment of overhead valves has caused considerable difficulty in the past as locknuts frequently worked loose. Although by no means so frequent in these days, the fault has not been completely eradica tdd.

In all overhead-valve engines the cylinder head must be more complicated than with a side-valve unit. This is not always conducive to ideal design, as modifications have frequently to be made to ensure the' incorporation of all the essential components, and this engenders more compromise

than 'would otherwise be necessary. J. PICKLES,