A Departure in the Application of Steam.

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

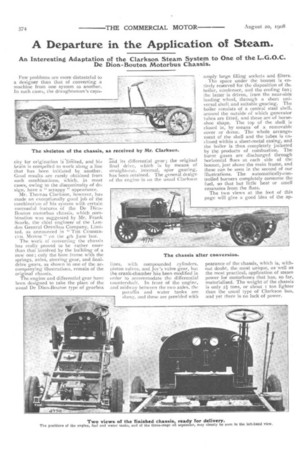

An Interesting Adaptation of the Clarkson Steam System to One of the L.G.O.C. De Dion-Bouton Motorbus Chassis.

Few problems are more distasteful to a designer than that of converting a machine from one system to another. In such cases, the draughtsman's capa city for origination is limited, and his brain is compelled to work along a line that has been initiated by another. Good results are rarely obtained from such combinations, Which, in most cases, owing to the discontinuity of design, have a " scrappy " appearance,

Mr. Thomas Clarkson, however, has made an exceptionally good job of the combination of his system with certain successful features of the De DionBouton motorbus chassis, which combination was suggested by Mr. Frank Searle, the chief engineer of the London General Omnibus Company, Limited, as announced in " TnE COMMERCIAL MOTOR " on the 4th June last.

The work of converting the chassis has really proved to be rather. more than that involved by the building of a new one; only the bare frame with the springs, axles, steering gear, and finaldrive gears, as shown in one of the accompanying illustrations, remain of the original chassis.

The engine and differential gear have been designed to take the place of the usual De Dion-Bouton type of gearbox

and its differential gear; the original final drive, which is by means of straight-cut, internal, spur gearing, has been retained. The general design of the engine is on the usual Clarkson

Hes, with compounded cylinders, piston valves, and Joy's valve gear, but the crank-chamber has been modified in order to accommodate the differential countershaft, In front of the engine, and midway between the two axles, the paraffin and water tanks are slung, and these are provided with

amply large filling sockets and filters.

The space under the bonnet is entirely reserved for the disposition of tht boiler, condenser, and the cooling fan; the latter is driven, from the near-side leading wheel, through a short universal shaft and suitable gearing. The boiler consists of a central steel shell, around the outside of which generator tubes are fitted, and these are of horseshoe shape. The top of the shell is closed in, by means of a removable cover or dome. The whole arrangement of the shell and the tubes is enclosed within a sheet-metal casing, and the boiler is thus completely jacketed by the products of coinbustion. The burnt gases are discharged through horizontal flues at each side of the bonnet, just above the main frame, and these can be seen in the second of our illustrations. The automatically-controlled burners completely consume the fuel, so that but little heat or smell emanates from the flues.

The two views at the foot of this page will give a good idea of the ap pearance of the chassis, which is, without doubt, the most unique, as well as the most practical, application of steam power for motorbuses that has, so far, materialised. The weight of the chassis is only 2,1. tons, or about i ton lighter than the usual type of Clarkson bus, and yet there is no lack of power.