Burton-based Marstons runs one of the most innovative and efficient

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

transport operations in the brewing industry. It wants to keep it out of the clutches of third-party firms like TNT and NCCS which have been calling time for the big breweries' in-house fleets.

• Marston, Thompson & Evershed is one of only a handful of small regional brewers left in the ale-making heartland of Burton-on-Trent, where giants Bass and Ind Coope dominate.

Yet, despite its size, it sets the pace in many technical and operational changes in brewery distribution. It is proud of the efficiency of its 100-truck operation, and this, says transport engineer Tony Tomlinson, staves of the temptation to go third party.

Marstons has run its own transport since 1904, and in the 1920s became one of the first brewers to use artics. In 1941, it began delivering bottles, kegs and barrels on one vehicle, while most of its rivals still used seperate trucks for each.

It was among the first brewery fleets to use 16-tonne trucks when they became legal in 1967, and says that in 1973 it was the first transport company to adopt Dunlop low-profile 70 Series tyres.

It has never used a three-man operation for its trucks. This practice dates back to the days of horse and dray, and many of its rivals have spent the past decade trying to call last orders on it.

It is courted from time by third-party operators, but does not see how a move from in-house distribution would be viable. Several of its regional rivals have gone to outside operations, however. Boddingtons uses TNT, and Wolverhampton & Dudley contracts part of its operation to NCCS. Both have reduced their costs: Wolverhampton & Dudley's recent annual statement acknowledged that signi ficant improvements in working practices had been achieved since NCCS won business from it in 1988.

But Marstons' distribution manager, Jim Gaunt, says that nobody has proved to him that they can do the job cheaper. "A third party has to make a clear profit of 20% and that can only be saved on labour costs. Our drivers get £165 for 39 hours. Road haulage rates are £118 for 40 hours and that's where they make their 20% from, he says.

"Running costs are identical no matter who does it. Our running costs are lower than some private hauliers. The only benefit would be that we could invest money — the capital expenditure for buying vehicles — in other fields. But third party companies would never give a better service than we give," says Gaunt.

GOOD RELATIONSHIP

Marstons has a good relationship with the Transport and General Workers Union, which represents its 136 drivers and transport staff.

Gaunt says its conditions are so good that drivers rarely leave. "The only time is when they are 55 or 60, we transfer them at their own wish to the brewery. But we have several still driving."

Marstons is an amalgamation of three breweries: Marston, Thompson and Evershed. Founded in the 1700s in Burton, it has been run in its present form since 1904. It operates six depots, in Winchester,

Wrexham, Malvern, Llandudno, Leighton Buzzard and Penrith. Beer is trunked from its brewery at Burton on artics and delivered to around 1,000 tied pubs and 1,000 other outlets, using rigids.

Wrexham, the biggest depot, runs 16 vehicles. Penrith, the smallest, has one 16-tonner and one 7.5-tonner.

Marstons' biggest pockets of pubs are in the north Midlands, North Wales and Manchester. At one time, it had nine depots, with additional breweries at Wrexham and Winchester. Its most recent closure was Macclesfield, which shut this year. "Motorways and better dual carriageways have meant rationalisation of distribution," says Gaunt.

All motorway deliveries are scheduled at 64kmph (40mph). The 321cmph (20mph) leeway gives drivers time to complete their turnaround, says Gaunt Every tachograph is checked and speeding drivers are disciplined. Marstons also has eight mechanics at Burton, where it handles all the fleet's servicing and signwriting.

Its fleet comprises 10 32-tonners — all Seddon Atkinson 301s and 311s — and 82 16to 17-tonners. Most are Seddon Atkinsons, with some Leyland Daf Freigh ters. It has also bought two new ERF ES6s. It runs 10 Leyland Daf Roadrunners on its one-person runs from smaller depots which do not justify a two-man operation.

Although the trend in pubs nowadays is for above-ground cellars, most are still beneath the street and two men are needed on each truck. Also, some 40% of its beer is still carried in 36-gallon (164 litres) aluminium barrels, rather than the conventional 18 or 22 gallon kegs (82 or 100 litres).

UNLADEN WEIGHT

The unladen weight of its 16-tonners has been is kept to a minimum, says Tomlinson, to achieve a 10-tonne payload, but the three vehicles it has bought since August have been 17-tonners with Boalboy curtain-sided bodies. They deliver Pedigree Premium Ale to Whitbread pubs as part of an exchange deal.

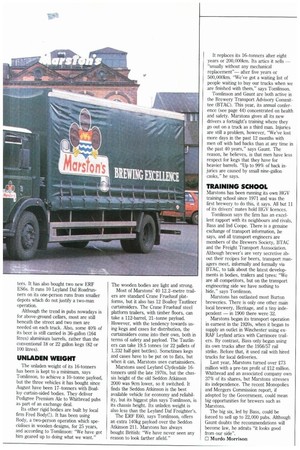

Its other rigid bodies are built by local firm Fred Body(!). It has been using Body, a two-person operation which specialises in wooden designs, for 25 years, and according to Tomlinson: "We have got him geared up to doing what we want." The wooden bodies are light and strong.

Most of Marstons' 40 12.2-metre trailers are standard Crane Fruehauf platforms, but it also has 12 Boalloy Tautliner curtainsiders. The Crane Fruehauf steel platform trailers, with timber floors, can take a 112-barrel, 21-tonne payload. However, with the tendency towards using kegs and cases for distribution, the curtainsiders come into their own, both in terms of safety and payload. The Tautliners can take 19.5 tonnes (or 22 pallets of 1,232 half-pint bottles). Sometimes kegs and cases have to be put on to flats, but when it can, Marstons uses curtainsiders.

Marstons used Leyland Clydesdale 16tonners until the late 1970s, but the chassis height of the old Seddon Atkinson 2000 was 9cm lower, so it switched. It finds the Seddon Atkinson is the best available vehicle for economy and reliability, but its biggest plus says Tomlinson, is its chassis height. Its unladen weight is also less than the Leyland Daf Freighter's.

The ERF E60, says Tomlinson, offers an extra 140kg payload over the Seddon Atkinson 211. Marstons has always bought British: "We have never seen any reason to look farther afield." It replaces its 16-tonners after eight years or 200,000km. Its artics it sells — "usually without any mechanical replacement"— after five years or 500,000km. "We've got a waiting list of people waiting to buy our trucks when we are finished with them," says Tomlinson.

Tomlinson and Gaunt are both active in the Brewery Transport Advisory Committee (BTAC). This year, its annual conference (see page 44) concentrated on health and safety. Marstons gives all its new drivers a fortnight's training where they go out on a truck as a third man. Injuries are still a problem, however, "We've lost more days in the past 12 months with men off with bad backs than at any time in the past 40 years," says Gaunt. The reason, he believes, is that men have less respect for kegs that they have for heavier barrels. "Up to 99% of back injuries are caused by small nine-gallon casks," he says.

TRAINING SCHOOL

Marstons has been running its own HGV training school since 1971 and was the first brewery to do this, it says. All but 11 of its drivers' mates hold IIGV licences.

Tomlinson says the firm has an excellent rapport with its neighbours and rivals, Bass and Ind Coope. There is a genuine exchange of transport information, he says, and all transport engineers are members of the Brewers Society, BTAC and the Freight Transport Asssociation. Although brewer's are very secretive about their recipes for beers, transport managers meet, informally and formally via BTAC, to talk about the latest developments in bodies, trailers and tyres: "We are all competitors, but on the transport engineering side we have nothing to hide," says Tomlinson.

Marstons has outlasted most Burton breweries. There is only one other main local brewery, Heritage, and a tiny independent — in 1900 there were 32.

Marstons began its transport operation in earnest in the 1920s, when it began to supply an outlet in Winchester using exRAF Leyland artics with Carrimore trailers. By contrast, Bass only began using its own trucks after the 1956/57 rail strike. Before that, it used rail with hired trucks for local deliveries.

Last year, Marstons turned over £73 million with a pre-tax profit of £12 million. Whitbread and an associated company own 37% of its shares, but Marstons stresses its independence. The recent Monopolies and Mergers Commission report, if adopted by the Government, could mean big opportunities for brewers such as Marstons.

The big six, led by Bass, could be forced to sell up to 22,000 pubs. Although Gaunt doubts the recommendations will become law, he admits "it looks good from our side".

0 Murdo Morrison