TIPPER TIMES ARE ACHANGING

Page 122

Page 123

If you've noticed an error in this article please click here to report it so we can fix it.

The tipper sector is being transformed by new materials and technology, but some buyers are conservative in their choice. Bodybuilder has been taking an overall look at the market.

• "When the sun shines, people buy tippers." This tongue-in-check assessment of the tipping body market comes from John Hope, sales director of Tasker. He admits there are rather more complex forces influencing the market; yet it is undeniable that the sun shone more than usual this winter and spring, and tipper sales have boomed almost as never before.

Moreover, there is little sign of any letup. Some of the bigger bodybuilders admit privately that their order books are full right through to August or September. Smaller companies have been almost embarrassed by the demand.

Some market sectors have been especially busy — notably the construction industry. Here, a trend towards bigger bodies has been marked. More rigid eight-wheeled tippers than six-wheelers are now being sold, and there is evidence that artics are coming more into their own for aggregates work.

This trend has naturally helped makers such as Crane Freuhauf, who are leaders in tipper trailers but build virtually no rigids. Paradoxically, though, Fruehauf s declared intention is to move into rigid tipper bodybuilding soon.

JUGGLING

The boom in artics has also prompted some juggling of production between plants by companies such as Wilcox, which aims to be "probably the biggest" rigid tipper manufacturer with production running at around 20 bodies a week. Wilcox has lately reopened a factory at Peterborough to separate rigid and trailer body production, and also has production capacity at Wisbech.

The York group, another leading market contender, has now concentrated both rigid and trailer tipper production on its Neville Charrold factory at Mansfield. Rigids tend to be marketed as Charrold bodies and trailers are York's, although the distinction is becoming increasingly blurred. However, topselling models such as the Ultralite aluminium aggregate body are still identified strongly with Charrold.

Designs in tipper bodies are running in two seemingly contradictory directions at the moment. In recent years there has been a trend towards more streamlined, horizontal-ribbed bodies — typified by the Don-Bur Streamlowda trailer, launched at last year's Tipcon show, Some of its features are in fact gaining in attraction generally — notably lowmounted tipping hinges to improve stability. Yet the streamlined features have not won it particularly extensive sales.

Indeed, there has been something of a conservative backlash in buying patterns. This is borne out by the popularity of Neville Charrold's recently relaunched Nimrod trailer — a classic "Bathtub" design (with one-piece vertical ribs hooped under a curved body profile). Crane Freuhauf s standard trailer offering has much the same general design (although Charrold claims exclusive rights to the Bathtub name). The feeling among operators seems to be that this style of body is stronger than the flat-panelled type. York group engineers say such a belief is not actually borne out by field experience, adding: "But the customer is always right, of course."

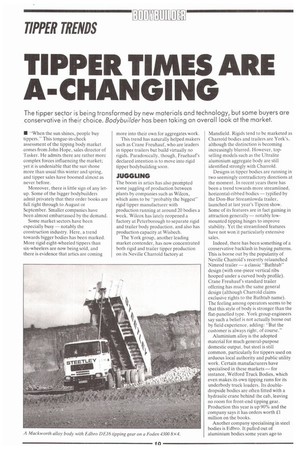

Aluminium alloy is the adopted material for much general-purpose domestic output, but steel is still common, particularly for tippers used on arduous local authority and public utility work. Certain manufacturers have specialised in these markets — for instance, Welford Truck Bodies, which even makes its own tipping rams for its underbody truck loaders. Its doubledropside bodies are often fitted with a hydraulic crane behind the cab, leaving no room for front-end tipping gear. Production this year is up 90% and the company says it has orders worth f million on the books.

Another company specialising in steel bodies is Edbro. It pulled out of aluminium bodies some years ago to avoid conflict with customers for its tipping rams, but still manages to turn out at least 20 bodies a week — many for military orders or export. To accommodate its flourishing bodybuilding work it has recently expanded back into a site it had previously closed.

In spite of apparent conservatism in the market, advanced features are gradually becoming more widely accepted. For instance, air suspension, initially regarded with caution by operators fearful of its vulnerability, weight and cost, is now establishing itself firmly in the tipping trailer market. Tasker reports 'great interest", and virtually all of Crane Freuhauf's tippers are now on air, even though incurring a premium of around £3,000 on a tri-axle model and about 200kg of extra weight. Reduction in tyre scrub and ability to lift the front axle and save tyre wear are reckoned to promise payback within a year or two.

CROSSMENIBERS

Step-frame chassis are becoming increasingly common for trailers, with crossmembers outrigged from the front floor section to keep the centre of gravity down. Recessed tipping rams are gaining popularity, giving better protection and allowing more body capacity (Stevecastle of Oundle provided an extra 5yd3 on a recent trailer of this design).

Meanwhile, Don-Bur has now produced what it claims to be the first allBritish tipping trailer with an aluminium chassis. A 62.5yd3 version of this special step-bodied chassis Supalowda, due to be shown at Tipcon, will have an unladen weight of just 5,850kg, and similar models with conventional flat floors are expected to follow.