• NEW DESIGNS OF LOCK-NUT.

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

Two Interesting Types : One British and One French.

TliE number of lock-nuts which has formed the subject of patent specifications can be counted in hundreds, if not thousands, but not many have achieved any real success or are to be found occupying a prominent place in the market. Some have proved overcomplicated, others ineffective when much vibration has been encountered, many are weaker than plain nuts of corresponding size, and it must always be remembered that from the point of view of cost there must not be too much difference between a lock-nut and a castle nut and split-pin. With locknuts of unusual type another trouble occurs. This is due to ignorance on the part of those who have dealings with the vehicle on which such nuts are employed after they have left the works of the manufacturers. It ma'y not be realized by them that the nuts are actually lock-nuts, and endeavours may be made to force them off, with drastic consequences; or, even if it be so 'realized, the means for unlocking them may not be understood, and the lastnamed should, therefore, be as simple as possible.

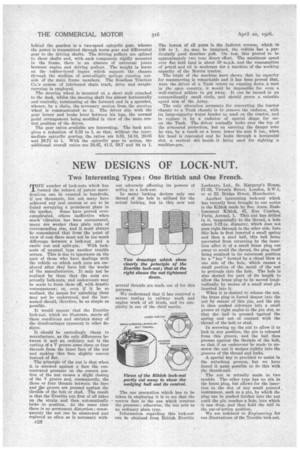

It would appear that the Evertite look-nut, which we illustrate, meets all these conditions and obviates many of the disadvantages apparent in other designs.

It should be exceedingly cheap to manufacture, as the only differences between it and an ordinary nut is the cutting of a V groove some three or four threads from the inner face of the nut and making this face slightly convex instead of flat.

The principle of the nut is that when it is screwed against a face the concentrated pressure on the convex portion of the nut causes a slight closing of the V groove and, consequently, the three or four threads between the face and,the groove are pressed against the threads of the bolt or stud. The result is that the Evertite nut first of all takes up the strain and then automatically Locks in position. At the same time there is no permanent distortion; consequently the nut can be unscrewed and replaced as often as is necessary with

out adversely affecting its powers of acting as a lock-nut.

In many locking devices only one thread of the bolt is utilized for the actual locking, but in this new nut several threads are made use of for this purpose.

We understand that it has received a severe testing in railway work and engine work of all kinds, and its simplicity is one of the chief merits.

The one precaution which has to be taken in employing it is to see that the convex face is the one which receives the pressure; otherwise, the nut acts as an ordinary plain type.

Information regarding this lock-nut can be obtained from British Evertite Locknnts, Ltd., St. Margare.t's House, 57-59, Victoria Street, London, S.W.1, or at 2Z, Bridge Street, Manchester.

Another interesting lock-nut which has recently been brought to our notice is the Kiblok made by Soc. Anon. Etablissement Kiblok, 47, Rue Cambon, Paris, Arrond. 1. This nut has drilled in it, tangentially to the thread, a hole about 3-32-in, diameter, which does not pass right through to the other side. Into this hole is first inserted a small spring and then a steel ball, this ball being prevented from returning by the insertion after it of a small brass plug cut away to avoid the thread, the plug itself being retained in its outermost position by a " key " formed by a chisel Mow at one side of the hole, which causes a small portion of the metal of the nut to protrude into the bole. The hole is also slotted for part of its length to allow the brass plug to be moved longitudinally by means of a small steel pin inserted into it.

When it is desired to release the nut, the brass plug is forced deeper into the nut by means of this pin, and the pin is then pushed sideways into a small groove at right angles to the pin slot, so that the ball is pressed against the spring and out of contact with the thread of the bolt or stud.

In screwing up the nut to allow it to lock in any position, the pin is released from this groove, and the ball then presses against the threads of the bolt, so that if an endeavour be made to unscrew the nut it wedges tightly into the grooves of the thread and locks.

A special key is provided to assist in the unlocking process, but we have found it quite possible to do this with the thumb-nail.

The nut is actually made in two models. The other type has no pin in the brass plug, but allows for the insertion in the slot of any small pointed instrument, such as a pin, by which the plug can be pushed farther into the nut until the pin reaches a hole, into which it can drop, and thus bold the ball in the out-of-action position.

We are indebted to Engiatzering for our illustrations of the Evertite lock-nut.