For DRIVERS, MECHANICS & FOREMEN.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to the sender of any letter which we publish on this page. and an E=A FIVE SHILLINGS to the sender of the one which we select as being the best each ieeek. AU notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faitr.. Address, D., M. and F., "The Commercial Motor," 7-15, .Rosebery Avenue, London, E.C. 1.

Lamps Alight.

On Saturday, April 24th, light your lamps at 8.39 in London; 9.6 in Edinburgh, 8.55 in Newcastle, 8.57 in Liverpool, 8.48 in Birmingham, 8.49 in Bristol, and 9.34 in Dublin.

Removing Steam Wagon Crosshead

The sender of the following communication has been awarded the extra payment of 5s, this week.

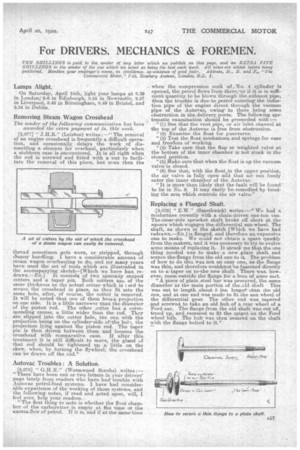

[2,077] " J.H.R." (Leiston) writes :—" The removal of an engine crosshead is frequently a difficult operation, and occasionally delays the work of dismantling a steamer for overhaul, particulaily when a stubborn case is encountered. It is all right when the rod is screwed and fitted with a nut to facilitate the removal of this piece, but even then the thread sometimes gets worn, or stripped, through clumsy handling. I have a considerable amount of steam wagon overhauling to do, and tor many years have used the set of tools which are illustrated in the accompanying sketch–{Which we have hact redrawn.—End It consists of two specially shaped cotters and a taper pin. Both cotters ate, of the same thickness as the actual cotter which is sed to secure the crosshead in place, as they fit into the same hole, after, of course, the cotter is removed. It will be noted that one of them basso, projection on one side. It is a little narrower than the diameter of the piston rod. The other zotter has a corresponding recess, a little wider than the. rod. , They are slipped into the cotter hole, the one with the projection being on the cylinder-side of.the holl, the projection lying against the piston rod. The taper pin is then driven between them and loosens the crosshead with comparative ease. If after this treatment it is still difficult to move, the gland of that rod should be tightened Up a little on the skew, when, by turning the flywheel, the crosshead can be drawn off the rod."

Autovac .Troubles : A Solution.

[2,078] " G.H.N." (Wormwood Scrubs) writes :— " There have been one or two letters in your drivers' page lately from readers who have had' trouble with Autovac petrol-feed systems. I have had considerable experience of the working of those systems, and the following notes, if read and acted upon, will, I feel sure, help your readers.

"The first thing to note is whether the floatchamber of the carburetter is empty at the time or the excess flow of petrol. If it is, and if at the same•time when the compression cock of ,No. 4 cylinder is opened, the petrol flows from there-'or if it is in sufficient quantity to be blown through the exhaust pipe, then the trouble is due!to petrol entering' the induction pipe of the engine direct through the vacuum pipe of the Autovac, owing' to there being some obstruction in the.delivery ports. The following systematic examination should be proceeded with

"(1) See that the vent pipe, or air inlet channel at the top of the Autovac is free from obstruction. " (2) Examine the float for punctures. "(3) Test the float 1=044111sta and springs for ease and freedom of 'working. "(4) Take care that the flap or weighted valve at the bottom of the inner chamber is not stuck in the closed position. "(5) Make sure that when the float is up the vacuum valve, is closed.

"(6) See that, with the float in the upper position' the air valve is fully open and that air can freely enter the inner chamber of the Autovac.

"It is more than likely that the fault will be found to lie in No. 6. It may dasily be.remediedhy bending the arm which controls the air valve,"

Replacing a Flanged Shaft.

[2,079] " E.W." (Smethwick) writes:—" We had a misfortune recently with a chain-driven one-ton van. The mem-side sprocket shaft broke off short at the square which engages thedifferential sun-wheel. The shaft, as shown in the sketch (Which we have had redrawn.—En.] is flanged, and therefore an. expensive one to make. We could not obtain a. spare quickly from the makers, and it was necessary to try to evolve some means of replacing it. It struck me that the one thing needed was to make a new .plain shaft and secure the' flange from the old one to it. The problem of how to do this was not an easy one, as the. flange was thin, and therefore couldinothe fastened directly on to-a-taper on to-the new shaft There was. however, room outside the flange for a boss of some suit. "A piece of plain steel bar was procured, the same diameter as the 'main portion of the .eld. shaft This was cut to length about 5 ins. longer i:han the old one, and at one end was made to fit the Kim wheel of the differential gear. The other end was tapered and screwed to take. an old Itub.of a rear wheel of a Ford car. The flange.from the old shaft was cut off, trued up, and recessed to fit the spigot on the Ford wheel hilb. The huh was then secured on the shaft with the flange bolted to it."