WARM

Page 92

Page 93

Page 94

If you've noticed an error in this article please click here to report it so we can fix it.

AND WELL OILED

ACCURATE temperature control of engine coolant and a matching lubrication system are essential to stop-start work and always beneficial.

Some time before the Hitler war Sir Harry Ricardo produced evidence that cylinder wear could be caused by acidic products of combustion. The rate of wear could far exceed that normally produced by abrasion if engine temperature was not kept high enough to evaporate acids and enable them to be exhausted.

The necessity for rapid warming-up was also recognized by Sir Harry at this early stage.

The acids produced during combustion (notably those derived from oxides of nitrogen) are particularly harmful if they penetrate to the sump with the blow-by gases to contaminate the lubricant. And the mileage or time interval at which it is advisable to change the oil may largely depend on acid accumulation.

Certain types of branded additive-treated oils have been developed that provide a degree of acid neutralization. But no lubricant affords near complete protection for the normal mileage between overhauls.

All engine-makers and some operators are now fully aware that running at well below normal operating temperature can be highly injurious to pistons, piston rings and cylinders and increases fuel consumption.

The high cost, however, of providing control in all ambient temperatures (even the British range) has been a deterrent to adopting more sophisticated control systems. And for vehicles that cover long distances with a full load more advanced forms of temperature control are a desirable refinement rather than a valuable means of saving wear and tear and reducing fuel consumption.

A substantial improvement over an adequate mileage between engine overhauls is normally far less important to an operator than an improvement of the same order in the case of an engine that has to be overhauled at a low mileage.

Mileages now attainable with heavier vehicles operating long distances are so favourable that the promise of a considerable extension is often of academic interest. The reward is too remote and the vehicle will be replaced before any advantage accrues.

The chief engineer of one of the major vehicle manufacturers has stated that ideally an engine should be equipped with radiator shutters, a high-output fan with a thermostatically controlled clutch, a wax-type thermostat and a highly pressurized cooling system of comparatively small capacity. But the average operator is not sufficiently temperature-conscious to appreciate the longer-term benefits such a combination would provide and would be unwilling to meet the extra cost..

Highly beneficial Of related interest (as mentioned in Technitopics of Fram Filters) claims that employing a by-pass filter in conjunction with a full-flow type can be highly beneficial in terms of wear rates (despite the fact that the latter is a first necessity). This is because a large pressure drop is acceptable with a by-pass filter and a finer element can therefore be used than for a full-flow unit.

A dual filtration system may also enable the oil-change period to be doubled or trebled without increasing wear and tear.

These comments highlight the onus on an operator to evaluate the advantages of improved temperature control, and if necessary to modify the lubrication system, with due regard to the particular operating conditions of his vehicles.

Even if these operations involve day-byday stop/start running, appropriate measures (although falling short of the ideal combination) may boost mileage between "intermediate" overhauls by 300/400 per cent. Big savings in annual overhaul costs are possible.

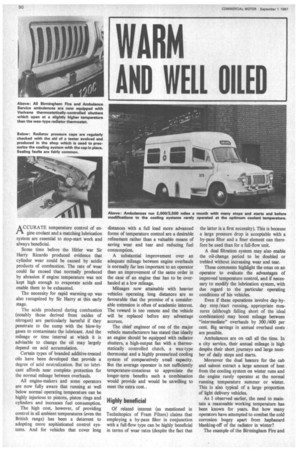

Ambulances are on call all the time. In a city service, their annual mileage is high despite their short journeys and large number of daily stops and starts.

Moreover the dual heaters for the cab and saloon extract a large amount of heat from the cooling system on winter runs and the engine rarely operates at the normal running temperature summer or winter. This is also typical of a large proportion of light delivery vehicles.

As I observed earlier, the need to maintain a reasonable working temperature has been known for years. But how many operators have attempted to combat the cold corrosion bogey apart from haphazard blanking-off of the radiator in winter?

The example of the Birmingham Fire and Ambulance Service is one which many other operators could profitably follow. It is a practical exercise aimed at exploiting the merits of proved accessories without undue complication.

Significantly, the engine-maker later followed the example of the department in the case of certain detailed modifications by standardizing the equipment used.

Five years ago Bedford A2 and Jl petrol engines had to be stripped after covering between 10,000 and 20,000 miles to renew the pistons. This followed seizure and breakage of the top piston rings—sometimes fracture of the piston lands—caused by acidic corrosion.

Since modification they now cover 40,000, sometimes as much as 80/100,000 miles before stripping is required. The resultant reduction in maintenance has achieved a valuable increase in vehicle use.

The fact that the power units are petrol engines is not particularly significant. Some years ago, an investigation was made of piston-ring and land trouble developed by the BMC 2.1 1 diesel engines of a fleet of light-delivery vehicles at 'mileages around 15 /17,000, which showed that low-temperature running can have an equally deleterious effect on compression-ignition engines.

The vehicles were driven by salesmen with many long waits, and deterioration of the pistons and rings was as rapid during summer as in winter. Engines of this type normally run for some 100,000 miles before stripping is required when the vehicle is used for long-distance work or operates from a heated depot with few stops and starts. In a 1962 survey of factors that might contribute "to early piston failure, Mr. R. L. Finlayson, chief engineer of Birmingham Fire and Ambulance Service, liaised with technicians of the Shell Research Centre at Thornton. They lent the department a temperature recorder of the thermocouple type to obtain continuous temperature readings during typical runs. This showed that the engines ran at lower-than-normal temperatures most of the time. Subsequently, all the ambulances were equipped with Varivane thermostatically controlled shutters and the ether-capsule-type thermostats were replaced by the wax-capsule type.

The engine thermostat opens the coolant valve at about 85deg C. The shutter thermostat operates at a somewhat higher temperature, which gives progressive control of the coolant temperature.

Fitted with a jiggle pin that obviates circulation through the bleed hole when the valve is closed, the wax thermostat gives improved control of coolant temperature. This is because it is not responsive to coolant surge, which can cause "gulping" and spasmodic release of jacket water to the radiator at relatively low temperatures. In severe winter, circulation through an uncontrolled bleed hole is sufficient to overcool the engine when operating continuously under load.

Regular checking Workshop practices introduced later by Mr. Finlayson to ensure efficient functioning of the cooling system include regular checking of the pressure caps with a tester, evolved and produced in the shops, which is used to pressurize the system with the cap in place, sealing and functioning faults being fairly common.

To conserve coolant (and antifreeze) one of the systems has been equipped with an expansion tank, which virtually obviates topping up, and it is planned to equip most vehicles with such tanks in due course. Fitted as standard by the vehicle manufacturers, a deflector behind the fan reduces cooling of the rocker cover by direct air blast.

Blended to the specification of Birmingham City Transport, a Supplement 1 type lubricating oil (BCT20S) is used for all the engines of the department's vehicles apart from experimental applications and units being run-in, for which straight mineral oil is employed.

The oil is changed at monthly intervals a mileage of 2,000/2,500 compared with a change mileage of 800 recommended by Vauxhall Motors for stop-start running. The oil has been approved by Bedford and its level of detergency is sufficient to prevent formation of cold sludge between changes.

Although the BCT2OS oil costs only 3s a gallon, an oil change at 800 miles would be uneconomic in terms of labour costs and loss of vehicle utilization.

The cost of a branded heavy-duty highly detergent oil (as used experimentally in the Rolls-Royce B81 petrol engines fitted to several fire appliances) is 9s a gallon. An offer to use this oil for the ambulance engines if the oil company would guarantee double the mileage between overhauls was not accepted.

Modifications initiated by the department and since standardized by Bedford include full-flow filtration (with a paper-type element AC filter) and a crankcase ventilating system incorporating a breather with a plastics element that also acts as a water-vapour trap and is serviced about once a week. In conjunction with ventilation of the sump and valve chest to the intake, the filter effectively prevents moisture build-up in the sump.

Apart from the high oil consumption associated with piston rings that have not bedded in, the resultant blow-by can be injuriously excessive. So in addition to running-in on mineral oil, the department employs Hepolite KTP piston rings with a Cargraphed graphited finish which accelerates bedding-in.

Supplied by the Associated Engineering Co., Apex oil-control rings have been fitted to an engine with 0.010 in bore wear and oil consumption has been negligible over a considerable mileage. The carrier of the Apex ring acts as an expander without bottoming in the groove.

The full-flow filter is of particular benefit during running-in. When the by-pass type was fitted subsequent analyses of the oil revealed that the lubricant contained some grit, notably in the oil derived from the first change. Used oils are regularly analysed in the BCT laboratories.

Automatic oil replenisher

To obviate the possibility of oil deficiency and further reduce the work, an automatic oil replenisher is being fitted to one ambulance and if successful may be adopted as standard equipment.

Produced by N. Frankmann Ltd., Cherry Croft, Wigan, Lancs, the replenisher essentially comprises a lgal reservoir, and a float chamber attached to the sump at an appropriate level.

The advantages of a "controlled" type of fan are fully recognized by Mr. Finlayson. But he feels it is a costly and complex refinement which would not be justified in existing circumstances without proof of reliability and performance in routine service.

Mr. Finlay-son observes that a fan is only required in extreme conditions and that its high inertia imposes strain on the belt drive during deceleration, particularly a belt driving an alternator operating under high load.

The peak load of the Lucas alternators of Birmingham's ambulances is around 20amp and belt trouble is frequently experienced with a single-belt drive system. Several vehicles have been satisfactorily fitted with dual belt drive.

I have mentioned that an additivetreated oil can be used to combat cold corrosion, but it is doubtful whether a high detergency level as such provides resistance to corrosion. An alkalinity additive is necessary for worthwhile results.

This is borne out by the authoritative report of an operator that changing from a mineral to a Supplement I type of oil increased the rate of corrosive wear about fourfold despite the elimination of cold sludge.

Could it be that the sludge absorbed the acids and thus prevented their circulation with the oil? Sludge is not necessarily harmful if it does not block the oilways.

Equipping an engine with an oil /water heat exchanger can be beneficial in two ways.

By providing more rapid oil warm up and maintaining a higher oil temperature during low-load running, it combats the formation of cold sludge. At the other end of the temperature scale it safeguards the engine against the formation of hot sludge (caused by oxidation of the oil) when it is running continuously near its peak load.

A heat exchanger should therefore be included in the cooling /lubrication equipment of the "ideal" engine which would then comprise:— • A highly pressurized radiator of reduced size equipped with a separate expansion tank and de-aeration system.

• A high-output fan equipped with a thermostatically controlled clutch (or feathering device).

• Thermostatically controlled shutters.

• A fully ventilated crankcase with filtered breather cap.

• A fine-element by-pass oil filter in addition to a full-flow type.

• An automatic oil replenisher.

• An oil/water heat exchanger.

Temperature control can also be important in the case of the air filter particularly if under-bonnet temperature has been increased by the measures outlined and if the power unit is a diesel.

With both petrol and diesel engines, heating the intake air reduces its density and therefore the weight of air that is aspirated and the peak power that the engine can develop. Heated air aids distribution of the mixture of a petrol engine, but this does not apply to the unthrottled air of a diesel which only benefits from air heating in Arctic weather conditions.

In both cases reducing the temperature of the air when the engine is thoroughly warmed up tends to increase thermal efficiency and therefore to reduce fuel consumption.

On some diesel-engined vehicles, the air filter is mounted externally in a "dust-free" position. If the filter of a petrolor dieselengined vehicle is mounted under the bonnet, a means by which cooler air could automatically be directed to it when the underbonnet air reached a pre-determined temperature would be decidedly advantageous.

One operator of a diesel-engined fleet has fitted electric fans to blow cooler air on to the intake. He claims that this increases power and reduces fuel consumption.