Burning Old Engine Oil

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

IT frequently happens that a vehicle operating concern which is in a position to accumulate a large quantity of old lubricating oil requires also heat for a boiler. The oil may be made to supply much of the heat, at comparatively low cost, by the use of a Windle oil burner. This simple apparatus is marketed by Windle Oil-Firing (Sales), Ltd., 109, 'Colmore Row, Birmingham, whilst the London district agents are the Engineers' Universal Supply Stores, 25-29, Sumner Street, Southwark, S.E.1.

The Windle burner can be installed in any type of furnace or boiler, suitable linings being arranged. A good working fuel consists of twothirds waste oil and one-third crude oil. Thesupply is by gravity.

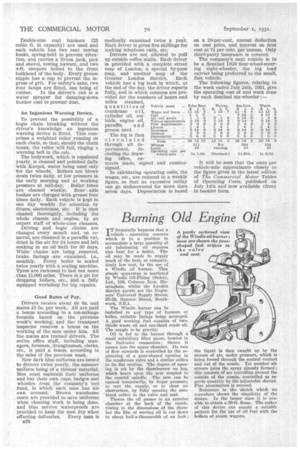

Oil is fed to the burner through a small subsidiary filter gauze, located in the fuel-inlet connection ; thence it passes into the upper chamber. Its rate of flow onwards is controlled by the registering of a pear-shaped opening in the mushroom valve and a similar orifice in its flat seating. The degree of opening is set by the thumbscrew on top, which bears upon the arm coupled to the control spindle. The arm can be opened temporarily, by finger pressure, to test the supply, or to clear an obstruction, by fully opening the combined orifice in the valve and seat.

Thence the oil passes to an annular chamber at the back of the nozzle. Owing to the dimensions of the chamber the film of moving oil is cut down to about half-a-thousandth of an inch ;

the liquid is then caught up by the stream of air, under pressure, which is being forced through the central venturi and out of the nozzle. Yet another air stream joins the spray already formed; this consists of air travelling around the outside of the nozzle, controlled as re. gards quantity by the adjustable shroud. Fine atomization is secured.

Reference to the sketch which we reproduce shows the simplicity of the design. In the larger sizes it is possible to obtain a 30-ft. flame. The maker of this device can supply a suitable pattern for the use of oil fuel with the boilers of steam wagons.