Contributions from Drivers and Mechanics.

Page 19

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY for the Best Communication Received, and One Penny a Line of ten words for any thing else published.

Drivers of commercial-motor vehic.es and trarters, and mechanics and foremen of garages or shops, are invited to send short contributions on any subject which is likely to prove of interest to our readers. Work. shop tips and smart repairs ; long and successful runs ; interesting

photographs : all are siiitable.subjects. Send a Post•card, or a letter, or a sketch to us—no matter low short, or how Teritten, or how worded. We will "knock it into shape" and prepare sketches, where necessary, before publication. The absence of a sketch does not disqualify for a prize. When writing use one side of the paper only and mention your employer's mime as a guarantee of bona fides. Neither your own nor your employer's 'tame will be disclosed. Payment will be made immediately after publication. Address your letters to The Editor, THE COMMERCIAL MOTOR, 7-15, Nosebery Avenue, London, E.C.

For,_Leaky Valve-stem Guides.

The sender of the following communication has been awarded the 10s. prize this week.

[756] " O.S.C." (Leamington) writes:—" I enclose a rough sketch [We have had this redrawn.—En.] showing a method by which badly-leaking valve-stem guides may be

temporarily cured, without dismounting the engine cylinders. It is generally found in most of the older-pattern eng,ines which are used for commercial work, that the valvestem guides are east with the cylinders, and, when these get badly worn, they cause a great deal of trouble. In the case of the exhaust valves, a great deal of noise is .caused by the escape of exhaust gas and the valve stems get burnt and corroded. In the case ofthe induction valves the carburation is badly affected at slow speeds. The usual thing that is then done is to enlarge the jet so as to enable the engine to pull well at slow speeds. This means that, when the engine is running at normal speeds, a great deal more petrol is used than is necessary.

'It is a big job for a small repair shop to attempt the boring out of the guides for the bushes, as. without special jigs, the holes would be almost certain to be out of truth with the valve seatings. I think my sketch is almost self-explanatory. A small collar is made for each valve. and this is drilled a nice working fit for the valve stem." Easy—When You've Thought Of It.

[757] " G.I3." (Thornton Heath) writes:—" I was recently engaged with a small firm of motor engineers as a mechanic. The work we had to do was principally repairs. One day our people were instructed by a client to send a man to bring a car home off the road where it was disabled. The vehicle in question was a light delivery van, and it had been left some days before by the driver, some 20 miles out of town. That, together with the address, was all the information I was given. Now I happened to overhear the instructions which were Oven to the foreman, and, not wishing for the job, T tried to dodge him! But it was no use; I was soon located, and given the necessary orders. Now, the reason that I did not want the job was that I bad an important private engagement that evening; in fact, I was shortly to be married, and there were some details to arrange that evening. There was no telling what time I should be back from the job. However, I knew it was no use pleading with the foreman ; a mechanic with private engagements—the idea! So, hastily packing my tool kit, I started offfor the station and just caught a train down. Arrived at the nearest station I found a threemile walk to the ear, which I found in the stable of a wayside inn. Whilst liquidating, I made some enquiries as to why the car had been left. I was told that the driver had brought it in some days before, having had help to push it for about 1-mile; and that, after working some hours on it, he had left it partly dismantled, and had gone home, saying he was ill. " On commencing work I found that the cylinder head, and a number of other parts of the engine were off. I set to work to reassemble, them. I found that a new paper joint between the cylinder and the head was re

quired, the old one having evidently blown. Perhaps that was the cause of the trouble, the damaged joint, possibly, letting water from the jacket into the cylinder I soon made a new joint, and bad the cylinder head in place before long. Next I found that one of the nuts forthe cylinder studs was missing. I searched, hut could not find it ; neither had I one in my kit, the engine being French, with, of course, metric screws. I could not see one on any other part of the machine, that could be spared.

" Now I was in a fix. No use attempting to run with

out that nut; the joint would soon go. I was three miles from the village, and it was very unlikely that I could get one there. I could wire or 'phone home, from the station three miles away, and have a nut sent per passenger train, or by road. But this meant time and expense, also that I should not be home in time for my engagement. I was tempted to go home, and return the next day with the required part; but that would have probably meant the sack. I set to thinking out a scheme in order to help me get over the difficulty.

Suddenly an idea struck me. (it literally struck me; I felt. it; I realized then the significance of the expression.) Why not make two nuts of one? This I was able to do ; I fortunately had a hacksaw in my bag and a hand vice which I clamped on to the car frame. I soon had a nut cut in two ; not, of course, diametrically, but in the middle of its length. The halves were rather thin, about the thickness of lock nuts. However, I reckoned they would be strong enough, with care. I soon had the rest of the machine fixed up, and, on starting up, I found it all O.K. I decided to run the engine easily, on a weak mixture, so as not to load the thin nuts with the maximum explosion pressure.

" All this had, of course, taken time, and I had barely two hours in which to do the 20 miles, so as to be back in time. I did it without mishap, and arrived a few minutes before knocking-off time. I was greeted by the foreman with Oh, you have come back; I began to wonder how much longer you were going to take over the job.' "

For Dirty Tanks.

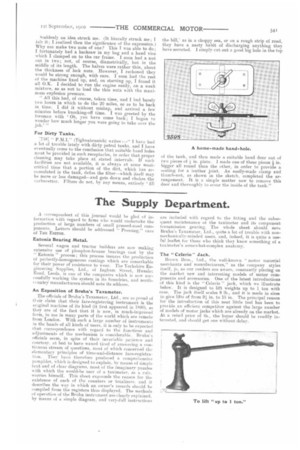

-758] " (Tiglina,bruaich) writes :--" I have had

a lot of trouble lately with dirty petrol tanks, and I have eventually come to the conclusion that suitable hand holes must be provided in such receptacles, in order that proper cleaning may take place at stated intervals. If such facilities are not available, it is always at some mostcritical time that a portion of the dirt, which has accumulated in the tank, defies the filter—which itself may be more or less damaged—and gets down and chokes the carburetter. Filters do not, by any means, entirely fill

the bill,' as in a choppy sea, or en a rough strip of road, they have a nasty habit of discharging anything they have secreted. I simply cut out a aood big hole in the top of the tank, and then made a suitable hand door out of two pieces of in. plate. I made one of these pieces in. bigger all round than the other, in order to provide a seating for a leather joint. An easily-made clamp and thumb-nut, as shown in the sketch, completed the arrangement. It is a simple matter now to remove this door and thoroughly to scour the inside of the tank."