York: the Billy Graham Of the three-axle world

Page 68

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

THE TRI-AXLE trailer opz s initially been the most ar choice for 38-tonne on, many operators are I at three-axle conver-. )r their 4x2 tractive units. Truck Equipment, a subof York Trailers, has alangineered more than 50 sions to ERFr Seddon Atnr Scania and Volvo

and is further tailoring le to suit demand, e long term, the 6x2+2 lation may become the )ecause of the load cornty it offers, and in the term because it allows g tandem-trailer equip) be used.

e are several possible elves for the position of an xle on the tractive unit. A front-steer is, however, not a practical proposition as the fifth-wheel would need to be located well towards the front of the chassis to achieve sensible axle loadings.

With the second steered axle set further back, just ahead of the drive axle, the fifth-wheel can be mounted to allow for compliance of load distribution and to minimise on swing clearance, by placing it between the rear of the chassis and the trailer landing legs.

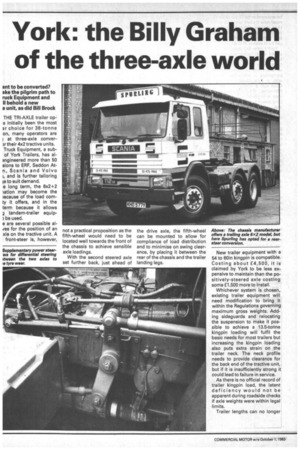

New trailer equipment with a 54 to 60in kingpin is compatible. Costing about £4,600, it is claimed by York to be less expensive to maintain than the positively-steered axle costing. some £1,500 more to install.

Whichever system is chosen, existing trailer equipment will need modification to bring it within the Regulations governing maximum gross weights. Adding sideguarcis and relocating the suspension to make it possible to achieve a 13.5-tonne kingpin loading will fulfil the basic needs for most trailers but increasing the kingpin loading also puts extra strain on the trailer neck. The neck profile needs to provide clearance for the back end of the tractive unit, but if it is insufficiently strong it could lead to failure in service.

As there is no official record of trailer kingpin load, the latent deficiency would not be apparent during roadside checks if axle weights were within legal limits.

Trailer lengths can no longer be assumed to be 12.2m (40ft) as most new trailers are built with that inside dimension. The overall length of an insulated box with front mounted fridge can be in excess of 12.5m (41ft).

York's other 6x2 option is described as a tractor conversion kit. The Bonus Loader makes a 6x2 out of a 4x2 without structural alterations to the chassis. It comprises a single-axle dolly with a forward-reaching neck fitted with a kingpin and Big-D fifth-wheel. When coupled, the load is imposed about 229mm (9in)•forward of the bogie centre line.

At first glance this might look to be a good option for any operator wishing to make a regular switch up and down weights between 32 and 38 tonnes. Unfortunately, legislation prohibits this. Unless it is used under a Special Types Order it runs into problems with plating. It can, however, be used as a permanent fixture but there is no cost advantage in doing so.

York believes it is possible to design a new 6x2 tractive unit with an overall wheel base of 3.5m (lift 6in) allowing a maximum unit weight of 20.33 tonnes, with a trailer bogie spread of only 1.2m (3ft 11in). This way it is technically possible to achieve maximum combination weight.

In the conversion of a 4x2 tractive unit to twin steer, by lengthening and strengthening the chassis with tapered flitching, a 3.8m (12ft 5in) wheelbase gives room for ancillary chassis components such as fuel tanks, air bottles and batteries to be mounted. Original steering gear is interconnected with the second steered axle giving the correct angle ratio to avoid scrub. The propshaft is lengthened, as is the exhaust for if this was left untouched it would overheat the tyres and the added axle.

The drive axle retains its original suspension but the second steered axle is fitted with air suspension, located by high deflection steel springs. Load here is governed by the loading of the drive axle.

The ultimate load compatibility is ensured by the inclusion of a fifth-wheel slider mounting.

For the trailing axle, it is the back end of the trailer which is extended and which increases the overall wheelbase. The drive-axle spring is either reworked or replaced to give a stiffer response; it connects the two rear-axles via an independent rocker beam which also serves to balance braking torque. A tried and tested design with more than 7,000 units in service, it adds only 1,000/1,400kg to the chassis unladen weight.

With the centre portion of the axle removed, stub axles allow for independent movement on each side. Normal load distribution of drive/trailing axle is 60/40 with single tyres and 50/50 if twins are used.

This ratio can be increased mechanically if greater drive traction is required, but with air bellows now incorporated as standard, the axle can be lifted clear of the ground for maximum load transfer, for tricky offroad conditions, or to save on tyre wear under light laden conditions.

As only small brake chambers are used with single tyred axles, the existing brake reservoir capacity is sufficient to satisfy the demand put upon it. Compared to the rear ste trailing axle concept may greater tyre scrub during manoeuvres but the lift fac likely to promote longer t\. overall.

The steering circle fo trailing-axle configuration normally be larger becat tyre scrub and the slightly I effective wheelbase. turning moment is taken the centre of the bogie fi trailing axle.)

The standard distan 2.13m (7ft) between the ki and landing legs is the ing dimension governing clearance. With the fifthmounting about 635 to 7! -(25 to 31in) forward of th steer's drive axle, and 1 (40in) ahead of the trailinc there is a clearance beni some two to six inches in , of the rear steer even after ing for the narrower width single-tyred axle.

York has looked at V self-tracking axle but think the system is slow to resp( changes in steering angl€ because it relies on scrul loads for operation, tyre will be greater than for a vely steered axle.

Gaining type approv vehicle conversion i converter's responsibility need not concern the OE However, most conversioi made to vehicles register( fore April 1 this year. They under the notifiable alte procedure which is quickE much less expensive.