Trailer Makers Look to Details

Page 88

Page 91

If you've noticed an error in this article please click here to report it so we can fix it.

Basic Designs Being Improved: Rubber Components Introduced to Save Wear: Interesting New Articulated Outfits

By P. G. Tucker BY comparison with a powered chassis, a trailer or semi-trailer, even in chassis form, rarely excites any great interest, This is probably because, having been accepted for so long as representing good practice, the basic designs have left the makers free to concentrate on improving their products in matters of detail.

Nevertheless, the Scammell concern have opened up new ground with their semi-trailer outfit of 24 tons gross weight, one example of which appears on Stand 83 and another, perhaps the more interesting, in the demonstration park. This is the first time that a vehicle of this size has been built for the home market, and until the proposed new Construction and Use Regulations are introduced it cannot be operated in this country,

Outstanding features in the design are concerned with the suspension system of the trailer bogie, the automatic coupling gear and Spherub turntable, and the parking legs, which are operated by compressed air (The Commercial Motor, September 24).

The semi-trailer shown on the stand has a similar suspension, but is not pro

o26 vided with the automatic coupling gear. Support for the semi-trailer when uncoupled is provided by a separate jack, the head of which takes a bearing on a built-in member of the chassis. Since the Crane hydraulic trailer was first introduced, the design of the bogie has been modified in a number of ways. The example shown (Stand 99) has three rows of four wheels, each row being suitable for an imposed load of 30 tons. Michelin Metallic G 20 tyres are used, these being the equivalent of 14.00 x 20-in. equipment.

As it has been possible to reduce the overall dimensions of the frame, the maximum width of the complete trailer can be brought down to 9 ft. 6 in., this permitting it to travel at 12 m.p.h. Previously the measurement was 11 ft., which restricted the legal speed to 5 m.p.h.

As the frame of the bogie is narrower, it has been possible to bring a number of important components outside it. These include the adjustable steering connections for aligning the wheels, and the electric motor and hydraulic pump unit.

Despite the use of 12 wheels on each bogie, there is no tyre scrub.

Some of the improvements include the elimination of chains in connection with the automatic steering and the use of hard chromium on the bores of the main hydraulic cylinders.

Cranes also have a rubber-mounted turntable, and a system of progressive springing in which the eyeless spring ends are mounted in specially shaped housings. Under light load conditions the spring ends bear on the housing over a small area, but as the load increases, so the effective length of the spring shortens to provide a stiffer member.

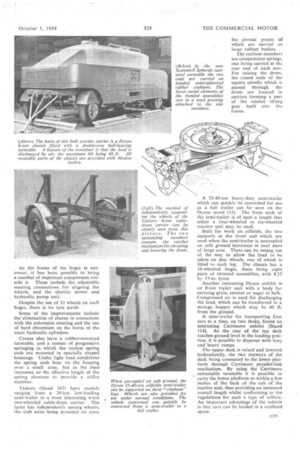

Taskers (Stand 107) have models ranging from a 20-ton low-loading semi-trailer to a most interesting 4-ton two-wheeled cable-drum carrier. The latter has independently sprung wheelst, the stub axles being mounted on arms the pivotal points of which are carried on large rubber bushes.

The resilient members are compression springs. one being carried at the rear end of each arm. For raising the drum, the round ends of the square spindle which is passed through the drum are located in carriers forming a part (If the ratchet lifting gear built into the frame.

A 35-40-ton heavy-duty semi-trailer which can quickly be converted for use as a full trailer can be seen on the Dyson stand (33). The front neck of the semi-trailer is of such a length that either a four-wheeled or six-wheeled tractive unit may be used.

Built for work on oilfields, the two supports, at the front end which are used when the semi-trailer is uncoupled on soft ground terminate in steel pans of large area. These can be swung out of the way to allow the load to be taken on disc wheels, one of which is fitted to each leg. The chassis has a 16-wheeled bogie, there being eight pairs of twinned assemblies, with 8.25 by 15-in. tyres.

Another interesting Dyson exhibit is an 8-ton trailer unit with a body for carrying grain, cement or sugar in bulk. Compressed air is used for discharging the load, which can be transferred to a storage hopper which may be 40 ft. from the ground.

A semi-trailer for transporting four cars at a time, an two decks, forms an interesting Carrimore exhibit (Stand 114). As the rear of the top deck reaches ground level in the loading position, it is possible to dispense with long and heavy ramps.

The upper deck is raised and lowered hydraulically, the two runways of the deck being connected to the lower platform through Carrimore parallel-link mechanism. By using the Carrimore retractable turntable it is possible to carry the lower platform to within a few inches of the back of the cab of the tractive unit, thus providing an increased overall length whilst conforming to the regulations for such a type of vehicle. An important advantage of the vehicle is that cars can be loaded in a confined space,