LIGHTER ST AND LIGHTER

Page 78

Page 79

Page 80

Page 81

Page 82

Page 85

Page 86

Page 87

Page 88

If you've noticed an error in this article please click here to report it so we can fix it.

Weight Saving and Adoption of Smaller Oil Engines for Use in Vans Most Noticeable Trends : New Passenger and Goods Integral-construction Vehicles Introduced, and Semiautomatic Transmission Available in Passenger Chassis by John F. Moon and Laurence J. Cotton,

M.I.R.T.E.

THE trend towards lighter chassis, which was noticeable at the Commercial Motor Show in 1952, is even more pronounced this year and is further emphasized by the appearance of three types of vehicle With integral construction, these including a doubledeck bus and a 8i-ton lorry. The small oil engine is now firmly established in the 2-ton and 3-ton ranges, and is used in several ambulance chassis. Many manufacturers are now building their own oil engines, as opposed to using proprietary components. Home operators, determined to beat the fuel tax, have shown a preference for slightly more expensive vehicles with lower running costs.

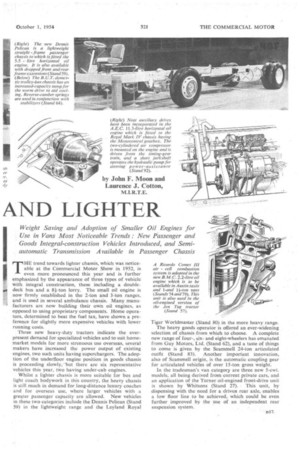

Three new heavycluty tractors indicate the everpresent demand for specialized vehicles and to suit homemarket models for more strenuous use overseas, several. makers have increased the power output of existing engines, two such units having superchargers. The adoptiim of the underfloor engine position in goods .chassis is proceeding slowly, but there are six representative vehicles this year, two having under-cab engines.

Whilst a lighter chassis is more suitable for bus and light coach bodywork in this country, the heavy chassis is still much in demand for long-distance luxury coaches and for overseas use, where larger vehicles with a greater passenger capacity are allowed. New vehicles in these two categories include the Dennis Pelican (Stand 59) in the lightweight range and the Leyland Royal:

Tiger Worldmaster (Stand 80) in the more heavy range. . The heavy goods operator is offered an ever-widening selection of chassis-from which to choose. A Complete new range of four-, sixand eight-wheelers has emanated from Guy Motors, Ltd. (Stand 62), and a taste of things to come is given by the Scammell 24-ton articulated outfit (Stand 83). Another important innovation, also of Scammelt origin, is the automatic coupling gear for articulated vehicles of over 15-ton gross weight.

In the tradesman's van category are three new 5-ewt. models, all being derived from current private cars, and an application of the Turner oil-engined front-drive unit is shown by Whitsons (Stand 27). This unit, by dispensing with the need for a driven rear axle, enables a low floor line to be achieved, which could be even further improved by the use of an independent rear suspension system.

An indication of future double-deck bus design is given by the Routemaster bus shown by A.E.C. (Stand 81). This was fully described in last week's issue of The Commercial Motor. This vehicle combines lightweight integral construction with a passenger capacity of 64 persons, within overall dimensions of 27 ft. by 8 ft. The unladen weight of 6 tons l4 cwt, is proof of the success of the design, but lower weights than this have been obtained by a combination of conventional lightweight chassis and alloy bodies.

Similarly, by using aluminium integral construction, Mann Egerton (Stand 121) have built a maximum-load four-wheeler which weighs less than 3 tons. This low weight has been achieved without in any way reducing

the practicability of the vehicle. It has components from the Dennis Centaur chassis, with the difference that the engine is horizontal instead of vertical.

With the exception of the Commer TS3 threecylindered opposed-piston two-stroke unit (Stand 72), engine design has followed conventional lines. The Cornmer engine, being almost cube-shaped, is extremely compact and its silence of running and high output, especially at low engine speeds, make it particularly suited to passenger-vehicle use.

This year attention is focused on smalland mediumsized oil engines. Not without note, however, is the fact that many manufacturers have increased the power of theirlarger engines for chassis primarily intended for export. By this means it is possible to build a more powerfully engined vehicle without having to make chassis modifications or, indeed, many engine alterations. Power has been increased mainly by altering fuelinjection-pump settings, modifying combustion chambers, raising the governed engine speed and, in the case of larger oil engines, by the application of turbosupercharging. Of the new engines, the B.M.C. 2.2-litre indirectinjection oil engine (Stands 74 and 79) is the smallest. This unit, which has the Ricardo Comet ill system of combustion, develops 55 blip. at 3,500 r.p.m. Although the maximum torque of 89 lb.-ft. is high up in the speed range at 2,500 r.p.m., suggesting that the engine would be more suitable for fitting in private cars, taxis and light delivery vans, the torque curve is reasonably flat above the 80-lb.-ft. mark between 1,000 r.p.m. and 3,000 r.p.m. This unit, which is offered as an alternative to the petrol engine in the B.M.C. 1-ton and 11-ton vans, in addition to the Austin taxi (Stand 88), has similar dimensions to the B.M.C. 46 blip. petrol unit. The C.A.V. fuel-injection equipment has a vacuum governor and injectors with Pintaux nozzles.

Direct injection is used in the B.M.C. 3.4-litre fourcylindered engine, which is employed in 2-ton and 3-ton vehicles, and has been successfully applied to ambulances. This engine is notable for itsquiet running, as is also the Ford unit of similar size. Both have Simms injection equipment, and a feature of the Ford engine (Stand 73) is that the exhauster is placed behind the pump, so as to reduce the possibility of the pump timing being affected by coupling wear.

Another oil engine in this range is the Albion 3.8litre, which, in vertical and horizontal versions, is used in the Claymore chassis (Stand 94). The vertical engine has a centrifugal governor, whereas the horizontal version has pneumatic governing. This is being used to reduce the overall depth of the engine. Further differences between these two units include a gear drive for the water pump and modified water passages in the horizontal engine.

The Standard 2.1-litre engine (Stand 68), which is used in the Vanguard van and pick-up vehicles, has Freeman Sanders combustion. This unit, which is used as a

conversion pack in taxis, is slightly slower-running than the B.M.C. engine, and is governed at 3,000 r.p.m., at which speed it develops 40 b.h.p. It gives an output of 19 b.h.:p. per litre as compared with the 25 b.h.p.

per litre of the B.M.C. engine. • The highest-output engine, shown by Fodens (Stand 60), also works on the two-stroke cycle and has a capacity of 8.2 litres, but its size precludes its use in any but the largest of tractors. It is basically two sixcylindered units, placed side by side and having a common crankcase. Dual fuel-injection and blower equipment is provided and the two cranks are interconnected by, helical gearing, the flywheel being fitted to the left bank to provide conventional rotation. The power output is 252 b.h.p., giving a power-to-capacity ratio of 30.7 b.h.p. per litre.

A new Rolls-Royce four-cylindered direct-injection oil engine (Stand 312), which is offered for road-vehicle use, is, an 8.1-litre unit which develops 123 b.h.p. at 2,100 r.p.m. and when supercharged, 167 b.h.p. Torque outputs are 340 lb.-ft. and 473 lb.-ft. respectively. The six-cylindered engine used by Scammell and E.R.F. develops 184 b.h.p. and 510 lb.-ft. torque, and is most suited to heavy tractors and load-carrying vehicles.

A Meadows horizontal four-cylindered engine (Stand 415) is new and has a cubic capacity of 5.4 litres, with a power output of 85 b.h.p. The Commer TS3 engine has been uprated from 90 b.h.p. to 105 b.h.p. by alterations to the fuel-pump setting. Turbo-blowers, which have formerly been used primarily on industrial and marine engines in this country, have been applied to three large oil engines, two being for road use. The Leyland 600 engine in supercharged form is fitted to the Super Hippo sixwheeled tractor, and has resulted in a power increase of 35 b.h.p. At 2,000 r.p.m. this engine now develops 185 b.h.p., whilst in normal aspirated form an increase in engine speed to 2,200 r.p.m. has resulted in a power output of 150 b.h.p. Although not yet applied to a road vehicle, the Leyland 680 engine, which normally develops 150 b.h.p., has been supercharged for railcar work and now has an output of 200 b.h.p. Similarly, Thornycroft have fitted a turbo-blower to their 11.3-litre engine (Stand 93), raising the power output from 155 b.h.p. to 200 b.h.p. at 1,900 r.p.m., and the torque by 117 lb.-ft. to 625 lb.-ft. at 1,000 r.p.m.

More Engine Power Also in line with the trend to produce more power from existing engines are the modifications which have Lteen effected on two other Thornycroft units. These are the TR6/1 5.5-litre engine, which now develops 90 b.h.p., compared with 78 b.h.p. at 2,200 r.p.m., and the TR6 /2, which has a power output of 68 b.h.p. at an increased engine speed of 2,200 r.p.m.. These greater power outputs have resulted from detailed modifications to the injection pump and its timing, and to the valvecam profiles.

With the introduction of the A.E.C. Reliance and the Mercury passenger and goods chassis, four new oil engines were built. These are horizontal and vertical versions of 6.75-litre and 7.75-litre units, and both have six cylinders, but differ mainly in respect of bore. The two engines, which develop 98 b.h.p. and 112 b.h.p. respectively, have power outputs directly proportional to their cubic capacity, but the Smaller engine, because it weighs only 45 lb. less than the larger, has a lower power-weight ratio. These units have a clean appearance externally, with fully enclosed belt drives to the dynamo and water pump, and a direct shaft drive to the forward-mounted fan.

Engine Modifications

The Dennis 5.5-litre vertical engine, fitted to the Centaur and Falcon chassis, has been modified for horizontal installation. This has entailed redesigning the cylinder head and alterations to the auxiliary drives. The dynamo and water pump are driven in tandem from the rear timing gears. The fuel-injection pump is well placed on this unit, being alongside the gearbox, where it is protected from road dirt, but easily accessible for maintenance. A mechanical governor is now fitted. This allows an easier flow of air into the engine because of the elimination of a venturi and has improved the volumetric efficiency. The power output has been increased from 87 b.h.p. to 92 b.h.p.

Other minor modifications to engine units include those applied to the Perkins P4, when fitted to the Dennis ambulance. A stepped sump is used to clear the front axle and the air cleaner has been moved to the rear of the engine, whence it is connected to the inlet manifold by a pressed-steel duct to reduce overall height.

Three important alterations have been made to the Daimler engine (Stand 71) to improve fuel consumption. A cold-air intake is now incorporated on double-deck bus chassis, with louvres on the top of the bonnet. The exhaustpipe bore has also been increased to lower back-pressure, and the number of vanes in the fluid flywheel has been reduced in order to improve the efficiency of the drive. On the Daimler underfloor-engined chassis, the fan has been reversed to force the air through the radiator from rear to front. This has been done to reduce the dirt accumulation between tubes and use fully the available area.

n20 An interesting method of weight saving has been applied on Albion home-market chassis, air for combustion being drawn in from the clutch housing instead of using a con. ventional air cleaner. A scoop at the side of the clutch housing allows clean air to be drawn into the clutch, where it is centrifuged by the rotating clutch before passing out to the engine. The amount of friction-material dust drawn into the engine in this way is negligible and any slight heating of the air which may occur has not been found to be detrimental to engine efficiency.

Micronic fuel filtering has recently been introduced on several chassis and has been standardized by E.R.F. (Stand 91). This system of fine filtering further reduces the chance of extraneous matter being drawn into the injection pump with the fuel. Rear mountings of the Gardner engine installed in E.R.F. chassis have also been altered. Metacone units are used for the clutch housing and the fifth mounting for the gearbox is no longer used. Not only does this give a more resilient mounting, but engine removal is simplified and weight and cost are reduced. In the Rolls-Royceengined heavy-duty tractor, however, a seven-point mounting is used with dual Metacone units on each side of the clutch housing and a support at the rear of the gearbox.

Several centrifugal clutches are now available as optional equipment to a fluid coupling when an epicyclic gearbox is fitted. ,Daimler offer the Twiflex clutch, which employs radial segments on rubber-bushed arms, and a new unit for use on A.E.C. engines is similar to a conventional frictionplate clutch, with the exception that engagement is effected by the outward movement of steel balls along radial grooves, thereby engaging the pressure plate.

The S.U. fuel-lift pump has for many years been popular in petrol-engined chassis, but it makes its first appearance in an oil-engined vehicle of the Trojan range. The pump is mounted, together with the fuel filter, in a tray which is attached to the front bulkhead. The components are thus neatly grouped for maintenance purposes.

The semi-automatic gearbox has come to the fore since the last Show, both A.E.C. and Leyland having developed units of this type. The use of these transmissions not only esults in a smoother ride for passengers but also reduces hiving fatigue. In both systems, which are not preelective, the bands of the epicyclic boxes are applied by air iressure, but whereas the Leyland pneumo-cyclic system tas air-control valves which are directly operated by the !river's change-gear lever, the A.E.C. Monocontrol utilizes olenoid-operated valves on the box itself. A further nnovation on the A.E.C. box is an automatic epicyclic iverdrive. This is a compact unit, attached to the nose of he gearbox, which automatically cuts in under the action if the hydraulic pump, depending upon the road speed and :ngine-torque conditions.

Increased use is being made of synchromesh gear engagenent, as seen by new boxes in the vehicles of A.E.C., :ommer and Leyland. The A.E.C. gearbox has been leveloped for use with Reliance passenger chassis and lifercury goods chassis, whilst the Commer box is a heavyluty unit made to accommodate the high-speed torque of he TS3 oil engine. The Leyland synchromesh unit is used n conjunction with an auxiliary and a transfer box on the Aartian 6 by 6 heavy-duty tractor. The transfer box on his is a three-speed unit incorporating two overdrive and Dne underdrive ratio, giving a combination of 12 speeds. A synchromesh box is also used in the new Seddon forward-control 8-tonner, this being the same unit as is fitted .o the Pennine central-engined coach chassis.

The advantages of an overdrive unit for increased fuel economy, especially when running unladen, are receiving ,ncreased attention by manufacturers. One of the neatest Dverdrive gears is that offered by Albion. This is a simple vacuum-operated epicyclic train which fits between the engine and gearbox and increases the length of the unit by Dilly %I in. By fitting the overdrive behind the engine, the size of the component has been kept small because it is not required to transfer a higher torque than the output of the engine. An overdrive with a dog-clutch-engaged constantmesh unit to the rear of the five-speed gearbox is used on the Thornyeroft Trident chassis.

A David Brown 557 gearbox is employed in both the new Mack trucks, the long-wheelbase version with an overdrive Lop-gear ratio. Atkinson (Stand 58) also fit a 557 gearbox in the double-deck bus chassis, but this has a specially constructed gearease to reduce the height of the box. Mainshaft and layshaft are arranged side by side and the gear case is split along their centre line. On Atkinson left-handdrive vehicles, a simplified form of gear linkage is used. This is achieved by mounting the selector mechanism on the side of the gearbox; the gear-change-lever bearing being bolted to the Gardner engine in the cradle which is normally used for dynamo mounting. This provides a more direct linkage and simplifies maintenance. A feature of David Brown gearboxes is that the reverse shaft is in constant mesh with the layshaft. Guy have made use of this in the Goliath range by taking the air-compressor drive from the reverse shaft, thereby throwing less direct strain onto the layshaft.

The Citroen 5-cwt. van (Stand 54) has front-wheel drive and the Turner power-and-drive unit also provides this. In the case of the Citroen, the power is taken to the wheels from the gearbox through bevel gears and telescopic universally jointed shafts. The gear-change arrangement is unusual, in that the lever slides through the front bulkhead, being connected to the selector mechanism by rod linkage. The Turner unit takes its drive from the back of the gearbox, through a transfer box and a propeller shaft which runs alongside the engine unit to the Land-Rover front axle.

The worm-drive rear axle, which for many years has held sway in passenger vehicles, shows signs of being displaced by bevel gearing, particularly in passenger chassis. The Guy lightweight Arab uses a hypoid final drive, and A.E.C. employ the Reliance-type axle in the Mercury goods chassis. Leyland, on the other hand, because of the high torque of the 680 engine, use a heavy-duty worm drive with 9-in. centres in the Wortdmaster passenger chassis. This unit is also fitted to the Super Hippo, because of the increased torque of the blown 600 engine. Seddon employ a worm drive for the first time in the Gardner 5LW-powered forward-control chassis, whilst an unusual feature of the new Albion Chieftain six-wheeler is the use of two overhead-worm axles. The higher transmission resistance of this arrangement will doubtless be offset by the increased traction available under slippery road conditions and the. distribution of the driving torque between the axles.

The rear bogie on the new E.R.F. 66R tractor is a heavyduty Kirkstall unit with overhead-worm drives which, because of its probable off-the-road use, incorporates no third differential. A heavier rear bogie has also been incorporated in the Sentinel trailing-axle six-wheeled models (Stand 90). This bogie has a sturdier trailing axle with a larger bearing area and a thicker beam; it also enables brakes of the same size as used on the driving axle to be fitted.

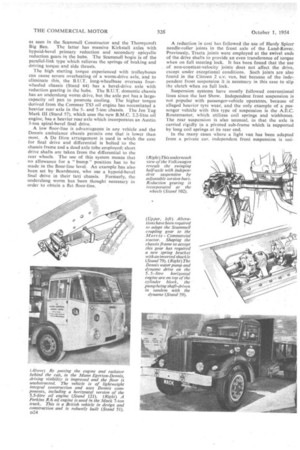

The use of heavy six-wheelers originally designed fot tractor working but which now, -in long-wheelbase form. have become load-carriers, has required stronger rear bogies, D23 as seen in the Scammell Constructor and the Thornycroft Big Ben. The latter has massive Kirkstall axles with hypoid-bevel primary reduction and secondary epicyclic reduction gears in the hubs. The Scammell bogie is of the parallel-link type which relieves the springs of braking and driving torque and side thrusts.

The high starting torque experienced with trolleybuses can cause severe overheating of a worm-drive axle, and to eliminate this, the BUT, long-wheelbase overseas fourwheeled chassis (Stand 64) has a bevel-drive axle with reduction gearing in the hubs. The B.U.T. domestic chassis has an underslung worm drive, but the axle pot has a largecapacity oil pan to promote cooling. The higher torque derived from the Commer TS3 oil engine has necessitated a heavier rear axle in the 5and 7-ton chassis. The Jen Tug Mark III (Stand 57), which uses the new B.M.C. 2.2-litre oil engine, has a heavier rear axle which incorporates an Austin 3-ton spiral-bevel final drive.

A low floor-line is advantageous in any vehicle and the Dennis ambulance chassis permits one that is lower than most. A De Dion arrangement is used in which the case for final drive and differential is bolted to the chassis frame and a dead axle tube employed; short drive shafts are taken from the differential to the rear wheels. The use of this system means that no allowance for a " bump " position has to be made in the floor-line level. An example has also been set by Beardmore, who use a hypoid-bevel final drive in their taxi chassis. Formerly, the undersIung worm has been thought necessary in order to obtain a flat floor-line. A reduction in cost has followed the use of Hardy Spicer needle-roller joints in the front axle of the Land-Rover. Previously, Tracta joints were employed at the swivel ends of the drive shafts to provide an even transference of torque when on full steering lock. It has been found that the use of non-constant-velocity joints does not affect the drive, except under exceptional conditions. Such joints are also found in the Citroen 2 c.v. van, but because of the independent front suspension it is necessary in this case to slip the clutch when on full lock.

Suspension systems have mostly followed conventional lines since the last Show. Independent front suspension is not popular with passenger-vehicle operators, because of alleged heavier tyre wear, and the only example of a passenger vehicle with this type of suspension is the A.E.C. Routemaster, which utilizes coil springs and wishbones. The rear suspension is also unusual, in that the axle is carried rigidly in a pivoted sub-frame which is supported by long coil springs at its rear end.

In the many cases where a light van has been adapted from a private car, independent front suspension is uni versa!, and one of the most interesting of these systems is that found on the Thames 5-cwt. van (Stand 73). Long coil springs are used, and through the centre of these run double-acting telescopic dampers. The Reliant Regal 5-cwt. van, with its single front wheel, has a torsion bar at the front, whilst its larger counterpart, the Regent 10 cwt., retains its established coil suspension. (Stand 50.) An interesting approach towards providing a more comfortable ride for ambulance patients is that used by Dennis in their new chassis. The Gregoire system has been employed. This consists of semi-elliptic springs with a reduced number of leaves and small coil springs which are tensioned between the chassis frame and axle. Under excessive bump or rebound conditions, these coil springs tend to increase the rate of the semi-elliptic type, and this results in a soft suspension without excessive bounding characteristics.

An interesting example of spring mounting which eliminates shackle pins is that used by Mack. The larger ends of the springs are carried in thick rubber blocks, which, in turn, are clamped to the frame by split anchor brackets. This system ensures that the spring mounting is unaffected by dirt or water and reduces maintenance, whilst providing a further measure of insulation for the frame from road ,shocks. • The anticipated appearance of disc brakes on passenger vehicles has not yet materialized (possibly because of the early high rate of wear of the friction pads), although it is known that several of the larger manufacturers arc conducting experiments with disc-brake systems in which the rate of wear has been reduced.

Air-pressure braking systems with diaphragm wheel units are becoming established on passenger vehicles in both the home and export fields. Leyland employ such a system on the Tiger Cub and Worldmaster chassis, whilst A.E.C. use it on their Reliance chassis. These systems incorporate a two-pressure control valve, whereby the initial application pressure causes sufficient retardation for normal braking, whilst further pressure on the pedal in emergencies releases a greater flow of air to the wheel units. To avoid accidental discomfort to the passengers, a strong spring has to be overcome before the second pressure can be used.

Exhaust brakes, whereby fuller use is made of the engine pumping power to effect retardation of the vehicle are also D25 in evidence. The Ashanco system, fitted to the A.E.C. Regal passenger chassis, is operated electrically by a pad on the brake pedal. The Leyland exhaust brake, on the other hand, is operated by a compressed-air unit with a separate hand control on the gear-change pedestal. This control can be left in position to allow the continuous use of the brake. when descending long gradients, without the need for the driver to hold it in position.

For goods vehicles there is a growing tendency towards

the ule of small air-pressure servos in conjunction with hydraulic braking systems. Such a system is advantageous, for the servo motor can be small and light and only a small compressor is needed, with a corresponding reduction in engine power losses, E.R.F. have standardized on this system for all their heavy vehicles; the Thomycroft Nubian 6 x 6 also incorporates it.

Because of the reduced pumping effect of the Cornmer TS3 two-stroke engine, the brake frictional area has been increased on vehicles fitted with this power unit, it is for this reason that larger shoes are now used on the rear axles of Commer vehicles.

Other general improvements to be noticed in braking include smaller drums at the rear axles, to allow greater circulation of air between the drums and wheels, also the use of ventilated wheel discs, the object of both being to promote cooling.

The Daimler C.V.G. lightweight chassis is an example of weight paring. Considerable weight has been saved on this chassis by dispensing with the lengthy boxing sections at the front of the frame and merely incorporating local boxing where it is required. An alloy steering box and extensive use of alloy for frame brackets has also reduced the weight. Leyland, on the other hand, have made little reduction to the Titan PD2 chassis, beyond having smaller tyres, batteries and fuel tank, and using an 8-in.-centre final drive. When fitted with a M.C.W. lightweight double-deck bus body, the total unladen weight is 6 tons 13 cwt. The A.E.C. Regent V chassis with an AV 470 engine and lightweight running components, when carrying a Crossley 61-seat body, turns the scales at 6 tons 9f cwt. This vehicle is conventional in every respect, whereas the Routemaster is a revolutionary vehicle, incorporating alloy integral construetion.4 This vehicle has seating for 64. and the unladen weight is 6 tons 141 cwt.