Bodies that Del the Goods

Page 92

Page 93

Page 94

Page 103

Page 104

Page 105

If you've noticed an error in this article please click here to report it so we can fix it.

r Life and Greater 6,ility in Tippers:

Rivalling Metal and : Demandfor Specialvpes Grows, but Inter?ability is Required By P. A. C. Brockington, A.M.I.Mech.E.

THE operator's attitude towards bodywork has become as demanding as his outlook on the mechanical tharacteristies of the chassis, but the bodybuilder has not been found wanting.

Take the example of the tipper. The operator is acutely conscious that an unsuitable body can mar the performance of an otherwise admirable vehicle. If the body is too light, maintenance costs and off-service losses can convert a potential profit into financial embarrassment; if it is too heavy, earning capacity is reduced and fuel is consumed wastefully; or it may be too long, too high or too shallow.

Robust construction may be more important than a reliable power unit, which is sometimes more easily replaced, or it may be quite unnecessary. The floor surface may be at fault because it encourages the material carried to stick, or it may be too slippery.

Providing replacement parts for damaged tipping bodies is a policy that is new, practical and commendable. It is one that has been developed by G. E. Neville and Son, Ltd. in the design of a light-alloy 6-cu.-yd. body comprising bolted ribbed sections, and it will be applied to a variety of sizes. Moreover, it will be extended to include the supply of knocked-down sets for bodybuilders and for enterprising operators who wish to convert vehicles in their own fleet. It can be seen on Stand 110 at the Commercial Motor Show.

The sections are special extrusions with external T-shaped radial ribs which form the floor, floor framing, sides and side framing in a single integral piece of 9-in effective length, which obviate the use of cross-bearers by virtue of their

inherent strength and rigidity. The body shown is supported on aluminium channel-section longitudinals, to which the sections are gusseted, and is mounted on a Guy Otter chassis powered by a Gardner 4LW engine, the unladen weight being a few pounds less than 3 tons. The tipping gear is an Edbro unit located at the front of the body, and an Eaton two-speed axle is fitted.

A functional and attractive appearance is also a featurc of the 12-13-cu.

yd. light-alloy tipping body shown by the Eagle Engineering Co., Ltd., on Stand 98, and mounted on a Thornycroft RC/CR6/1 chassis. The body is constructed of corrugated sections (forming longitudinal ribs), with radiused floor corners, and is reinforced with extruded pillars, corner posts and capping rails, with sides that slope from front to rear.

An interesting detail that was introduced at the 1952 Show, and has since found favour amongst many operators, is a tailboard which is automatically locked as the body is lowered. The ram is of the Eagle slant type.

These exhibits are included in a large o32

variety of light-alloy tippers, the number of which has increased since the 1952 Show, but according to some chassis manufacturers, hauliers who have "gone back to wood construction" after experience with the light-alloy type, represent a force that cannot be neglected. The better quality of the timber now available may have given the light-alloy bodybuilder a more difficult market.

It is not unusual to hear the manager of a tipper fleet say that the mechanism

of his vehicles which gives the least trouble is the lifting gear, but some site conditions are such that even the best will not withstand them, and it was a foregone conclusion that new forms of gear, shown for the first time at Earls Court, would arouse great interest.

The problem of body stability on very uneven ground, particularly when the vehicle has to be moved forward to dislodge residual material, can be acute. Telehoist, Ltd. (Stand 75), claim that they can provide a solution.

A new Telehoist link gear is fitted to a Thomycroft Big Ben 6 x 4 chassis, on which is mounted an 11-cu-yd. dump body. Twin double-acting rams of

large diameter are pivoted to the levers of a mechanism having longer arms connected to the body frame by wellspaced links of robust proportions and pins of ample size, which relieve the rarnshafts of all but thrust stresses. The ram capacity exceeds 15 tons and it is claimed that the vehicle could be used to carry this weight when operating off the road or in countries where the regulations permit.

Leverage exerted by the rams is highest at the start of tipping and declines with an increase of speed as the body is raised. The tipping time to an angle of 70° is 18 sec. and the return time (with reverse action of the rams) is 12 sec.

The cam-and-roller tipping gear shown by Wood Hoists, Ltd. (Stand 48), fitted to an Atkinson S.746 chassis, also has the advantage that the leverage is highest when the load is greatest. The single heavy-duty ram is fixed in a hori

zontal position and carries a crosshead with two pairs of rollers which bear on tracks and engage with quadrantshaped cams attached to the body frame. A spring-tensioned cable is used to prevent overtipping.

The ability to release a measured proportion of the total load with each tip might be used greatly to increase the scope of tipping vehicles, and the five-compartment body on a Dodge 105P6 chassis exhibited by Edwards Bros. (Tippers) Ltd., on Stand 47 shows how simply this can be done. The four wooden partitions are hinged at the top and are held in position by two cams projecting through the floor. These are attached to rods controlled by levers on the off side of the body which are locked by pins. The ram is of the Edbro 3LNC heavy-duty type.

An interesting contrast in construction is provided by a comparison of the 10-cu.-yd. .light-alloy body on an A.E.C. Mammoth Major 3671K chassis, shown by Pilot Works, Ltd., on Stand 123, and an 8-ft.-5-in.-wide steel dump body on the Bromilow and Edwards stand (Stand 46). The latter body was built on a Leyland Super Hippo chassis for a Spanish operator. Both vehicles have twin-ram underbody gear.

The former is .tql.fipped with two hydraulic extensions with quick-release couplings, one at the front and one at the rear, for actuating the lifting gear of

a tipping trailer. The floor of the steel body is covered with 11-in. hard wood lining and an upper. .1-in. plate to resist the impact of heavy rock dropped from a grab or shovel.

Specialized design is often desirable. but may be economically too restrictive to justify its use. On Stand 77, Cocker are, however, showing a special body designed for the Metal Box Co., Ltd., 'for pallet loading and transport, but it can also be used as a general-purpose Luton van with relatively little additional weight, despite its rather abnormal height of 12 ft. 9 in.

The loaded pallets are placed by fork-lift truck on ball7castored lightalloy bogies at floor level. The bogies are used to transfer the load from the spring-loaded tailboard to the interior of the vehicle, or from the front rearwards, side doors being fitted behind the cab to facilitate loading when space is restricted at the back. The floor is covered with aluminium plate and the bogies are locked in the travelling position by pegs.

An important feature is the means provided for fitting detachable partitions on the centre line and transversely, so that loose goods can be carried in the space not occupied by the palleted loads, which are normally stacked to the height available. The body has a capacity of 1,400 en. ft. and can be pallet-loaded in under 10 minutes. It is mounted on a Seddon R6 passenger chassis. Details include an electric height indicator connected to a projecting feeler on the roof, Over 30 years ago the founder of J. H. Sparshatt and Sons, Ltd. (Stand • 76) designed a van with a sliding roof for overhead loading, and a modern version has . recently been developed with a body known as the sliding-tilt type to meet the renewed demand for such a vehicle. The movable part of the roof extends well below the cantrail and is fitted with pre-loaded roller bearings which run in extruded-section side-rail channels.

Two synchronized electric motors and a chain drive provide the motive pow-or, which is controlled by a switch in the driver's compartment.. The sliding section can be stopped in any intermediate position and the current is automatically cut off when either of the limiting positions is reached.

The controversy regarding the rein Live merits of steel, composite and lightalloy construction for van bodies and cabs continues, but it often takes second place to discussions on the potentialities of plastics. Their application to commercial vehicles is a new science and discoveries in the next few years may improve the already promising results obtained.

Compared with aluminium, many plastic materials have greater strength and resistance to denting and can be more easily formed. Impregnating with colour offers the possibility of obviating painting costs.

As announced in The Commercial Motor last week, the main body panels of the 60-cu.-ft. van shown by the Reliant Engineering Co. (Tamworth), Ltd., on Stand 50. are of fibre-glass. A different approach to plastics development is indicated by the British Road Services straight-sided van body, built by University Commercials and Coachwork, Ltd., and exhibited by Dodge (Stand 61), which was described on September 10.

The special Wareite plastic of the Dodge van, bonded to a wire-mesh matrix to provide the flat panelling, might satisfy some users of other types of material, who hold the opinion that to employ plastics is uneconomic unless it saves the cost of panel beating.

The fibre-glass roof of the 1,660-cu.ft. pantechnicon displayed by Arlington Bodybuilders, Ltd., on Stand 25, and the comments heard on the Jensen stand (57) regarding plastics, are of related interest in that they confirm the potentialities of the material as a medium for the individual ideas of bodybuilders.

Ribs are formed in each of the nine sections of the Arlington van roof to give additional strength, and the sections are joined by riveting to the light-alloy channel-section roof sticks and by plastic strips bonded to the panels. The structural members and remaining panels are of light alloy and the unladen weight of the vehtde is under 3 tons. The chassis is a Bedford 4-tonner with a 3-ft. frame extension.

Use of Plastics Extended

Fibre-glass has been successfully employed by Jensen for some years in the construction of radiator grilles and, more recently, of cab roofs. Following the production of plastic bodies for cars, the material will probably be used later for panelling complete cabs, A container is another type of transport unit which is normally associated with specialized haulage, but it may enable the cost of seasonal specialization to be greatly reduced. The light-alloy bulk-cement container bulb by University and Commercials anti Coachwork, Ltd. (Stand 129), was designed for an operator who carries cement for only part of the year and often requires the Dodge 145R6 tipper chassis, on which it is mounted, for other duties.

The material is loaded through the roof and tipped through a conventional type of top-hinged tailboard. The frame members are of Homalloy heattreated extruded sections, To facilitate quick changes at short intervals, rather than seasonal transfers, was the object of the design of the light-alloy twin-deck cattle container built by Carmichael and Sons (Worcester), Ltd. (Stand 39). The external square-tube framing, the corner sections, cant-rail details and so on are of particular interest, as a similar form of construction could be used for pantechnicons and meat vans.

The Test of Time Conventional construction earns fresh laurels when it has withstood the test of time in competitionwith new forms of bodybuilding, and this is exemplified by the Guy Vixen 1,350-cu.-ft. furnitu.re van, with wood-framed body, which is displayed by Kingsland and Sons (Camberwell), Ltd., on Stand 44. Modern in appearance, it is modern also by weight standards. The full front is distinctive and original. The vehicle weighs under 3 tons unladen.

The framework is of ash and sapele, the uprights are reinforced with steel and the floor is of light alloy. It is claimed that the body is lighter than one of a comparable type having an allalloy structure.

A 555-cu.-ft. Luton van based on a. Commer Q25 chassis exhibited by B. Walker and Son, Ltd., on Stand 97, represents an outstanding example of lightweight steel construction. The welded-steel channel framing is reinforced with hardwood to provide a rigid structure, but the unladen weight of the vehicle is under 2 tons.

The market for small commercial vehicles based on low-priced car chassis is valuable to vehicle makers, and acceptability by operators often depends to a marked extent on the bodywork. Two important vehicles in this class are the 5-cwt. van shown by the Austin Motor Co., Ltd., on Stand 74, and the 6-cwt. van displayed on Stand 68 by the Standard Motor Co., Ltd.

These contrast in type with the Reliant three-wheeler with a 60-cu.-fl. body, already mentioned in connection with plastic construction, and the 5-cwt. van exhibited by Citroen Cars, Ltd., on Stand 54.

A notable feature of the Austin is the single rear door, which facilitates loading, and other details include underfloor mounting of the spare wheel inside the body, pegs which support the door in the closed position, and efficient waterproofing.

The Standard, like the Austin, is of integral construction, which increases the importance of the basic body design; it has a capacity of 90 Cu. ft. and a loading height of 1 ft. 8 in.

The ribbed one-piece section which forms the upper portion of the Citroen van body (of 66-cu.-ft. capacity) gives a rugged appearance, but combines

B18 strength with lightness. The square wheelboxes are extended forward to form lockers for the spare wheel on one side and the petrol tank on the other.

A high floor necessitated by an engine mounted at the rear above axle level would not appear to be conducive to ease of loading, but on the drop-sided pick-up displayed by Volk swagenwerk G.m.b.H., on Stand 102, this feature is combined with a spacious full-width underfloor locker into which heavy implements and so on can be more easily loaded than is possible with a conventional pick-up.

Some bodies at the Show belong to an"esoteric" group, in that they are so specialized that the interest of the average operator is that of a layman. These include bulk-haulage containers with complex discharge mechanisms, and the large tankers.

In the 14-ton bulk flour vehicle based on a Leyland Octopus eight-wheeled chassis, shown by the Duramin Engineering Co., Ltd., on Stand 31, a scientific airslide discharge principle is employed to provide forced ejection at the rate of 20 tons an hour. On Stand 61, Dodge display the bulk cement tipper developed for the Amalgamated Roadstone Corporation, Ltd., and described in the September 10 issue of The Commercial Motor. At the rear of the vehicle a blower-fed discharge system is employed to aerate the material.

so that it can be lifted to a great height With a fairly low internal pressure.

The new 4,000-gallon tankers are al straightforward design, but detailed improvements have been made in mounting methods to accommodate distortion and in co-ordinating the layout of discharge systems with the depot equipment used. Insulating materials for tankers have also been improved.

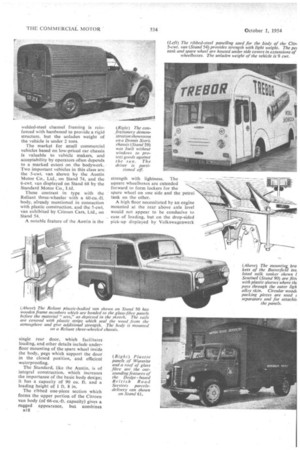

Notable examples of maximumcapacity tankers include the elliptical spirit tanker shown by Thompson Bros. (Bilston), Ltd., on Stand 103 and mounted on an A.E.C. Mammoth Major chassis, and a milk tank, . based on a 15-ton chassis, displayed by Atkinson (Stand 58). An interesting feature of the Butterfield 2,500-gallon tank on a Sentinel. DV46 underfloor-erigined chassis (Stand 90) is the method of attaching the outer light-alloy skin to the wooden separators. A plastic sleeve is fitted between the skin and the support bracket.

Outstanding in its class, the Abbotts light-alloy dray body on an E.R,F. chassis (Stand 91) is an example of a practical approach to the brewer's transport problem and his insistence on a vehicle that will uphold his reputation. Interesting features include side rails with spring-loaded catches and a lightalloy trolley with rubber-tyred wheels carried under the rear of the platform on loop-ended brackets.

The visitor who is interested in mobile shops is offered a large variety at the Show. For example, the butcher's shop shown by J. H. Jennings and Son, Ltd., on Stand 66 is mounted on a Karrier Bantam chassis and has a serving counter under cover at the rear. The mobile shop on a Bedford 4-ton chassis, displayed by Spurling Motor Bodies, Ltd., on Stand 101, is of the self service type in which the customers enter at the rear, walk the length of the vehicle collecting their purchases and pay at a cash desk near the front.

A netv form of rack construction, known as Bollorock, is a feature of the grocery shops exhibited by Smith's Delivery Vehicles, Ltd. (Stand 55), which are mounted on N.C.B. 1-ton and 2-ton battery-electric chassis, Thefl shelves facilitate tray loading and provide a secure fastening.

In a demonstration van, the preservation of the goods during a long tour is often a first importance, and this was the reason for eliminating windows in the design of the sweet showroom mounted on a Dennis Stork chassis (Stand 59). A small, comfortably furnished lounge is situated opposite the rear entrance, and at the front the entrance is completely separated from the driver's compartment. A similar chassis is employed for a hairdresser's showroom by Cocker (Stand 77).

"The driver should have the last word" appears to be the sentiment of many vehicle makers and bodybuilders with regard to both ease of entry and cab design. A 'display", cab with transparent panels fitted to an Albion Claymore underfloor-engined chassis (Stand 94) indicates the extent to which the vision and comfort of driver and passengers can be improved when the engine and transmission are no longer impediments and Leyland Motors, Ltd. (Stand 80), show their new steel cab with car-type swivelling ventilators.