SUNBEAM ENTERS THE LTTERY-ELECTRIC FIELD

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

MORE than an undercurrent has been flowing, during the past few years, towards popularizing the battery-electric vehicle. Simplicity of operation, cleanliness, silence and, above these, economy, make an appeal that, as it becomes more fully appreciated, grows more irresistible to operators of vehicles working under those conditions for which the special qualities of the type are particularly well suited. ' Different as are the battery-electric and the trolleybus types of vehicle, the two have big fundamental similarities. Whilst it is no novelty for a trolleybus maker to build also a chassis that relies for its power upon an accumulator, it is definitely significant, in more than one respect, that Sunbeam Commercial Vehicles, Ltd., Wolverhampton—the products of which, in the former class, are in regular service in the town of their manufacture, its adjacent borough Walsall, farther afield at Portsmouth, and overseas at Johannesburg, Durban and Rangoon—should add to its range of commercial vehicles a model in the latter class,

Good Chances for the Electric.

The significance lies in the fact that this company would not have entered this field unless it. saw sure prospects of the present position continuing, and probably improving, unless it was confident that it would not jeopardize its reputation by offering to commercial-vehicle users, or prospective users, a chassis that was not of equal excellence to those for which it is already renowned, and unless it was assured that the requirements of its Clients and, again, of their clients, would be advantageously served.

Moreover, it has carefully considered the economic position in respect of the generation and distribution of electric current.

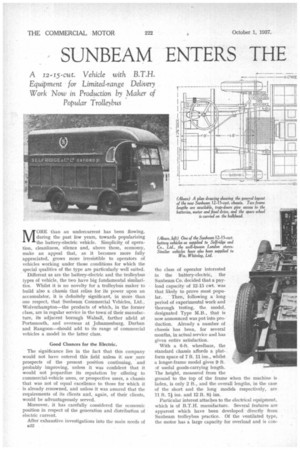

After exhaustive investigations into the main needs of 1302 the class of operator interested in the battery-electric, the Sunbeam Co. decided that a pay load capacity of 12-15 cwt. was that likely to prove most popu lar. Then, following a long period of experimental work and thorough testing, the model, designated Type M.B., that is now announced was put into production. Already a number of chassis has been, for several months, in actual service and has given entire satisfaction.

With a 6-ft. wheelbase, the standard chassis affords a plat form space of 7 ft. 11 ins., whilst a longer-frame model gives 9 ft. af useful goods-carrying length. The height, measured from the ground to the top of the frame when the machine is laden, is only 2 ft., and the overall lengths, in the case of the short and the long models respectively, are 11 ft. 7i ins. and 12 ft. Ki Particular interest attaches to the electrical equipment, which is of B.T.H. manufacture. Several features are apparent which have been developed directly from Sunbeam trolleybus practice. Of the ventilated type, the motor has a large capacity for overload and is con trolled by magnetic contactors basically similar to those used on the trolleybus, but, like the motor, adapted for employment with batteries. They are operated merely by depressing a pedal, which actuates the master controller.

The last-named comprises a series of switches of the interlock type, which close the contactorcoil circuits as the pedal is depressed. By this system the speed can be regulated in just the same way as on a petrol vehicle, whilst both hands are left free for steering, etc. Moreover, it renders it impossible for excessive arcing to occur through misuse of the controller.

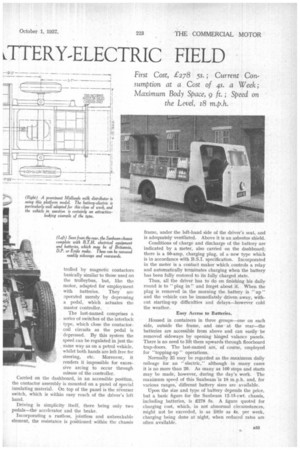

Carried on the dashboard, in an accessible position. the contactor assembly is mounted on a panel of special insulating material. On top of the panel is the reverser switch, which is within easy reach of the driver's left hand.

Driving is simplicity itself, there being only two pedals—the accelerator and the brake.

Incorporating a rustless, jointless and unbreakable element, the resistance is positioned within the chassis

frame, under the left-hand side of the driver's seat, and is adequately ventilated. Above it is an asbestos shield.

Conditions of charge and discharge of the battery are indicated by a meter, also carried on the dashboard; there is a 50-amp. charging plug, of a new type which is in accordance with B.S.I. specification. Incorporated in the meter is a contact maker which controls a relay and automatically terminates charging when the battery has been fully restored to its fully charged state.

Thus, all the driver has to do on finishing his daily round is to "plug in" and forget about it. When the plug is removed in the morning the battery is " up" and the vehicle can be immediately driven away, without starting-up difficulties and delays--however cold the weather.

Easy Access to Batteries.

Housed in containers in three groups—one on each side, outside the frame, and one at the rear—the batteries are accessible from above and can easily be removed sideways by opening hinged valance panels. There is no need to lilt them upwards through floorboard trap-doors. The last-named are, of course, employed for "topping-up" operations.

Normally 35 may be regarded as the maximum daily mileage for an "electric," although in many cases it is no more than 20. As many as 160 stops and starts may be made, however, during the day's work. The maximum speed of this Sunbeam is 18 m.p.h. and, for various ranges; different battery sizes are available.

Upon the size and type of battery depends the price, but a basic figure for the Sunbeam 12-15-cwt. chassis, including batteries, is £278 5s. A figure quoted for charging cost, which, in not abnormal circumstances, might not be exceeded, is as little as 4s. per week, charging being done at night, when reduced rates are often available. The chassis weighs, without accumulators, 12 cwt. 2 qr. It has a main frame of high-tensile-steel pressings, generously braced by sturdy cross-members. It is dropped at the front and gives a low cab floor, and affords easy entry and exit for the driver—an important point on house-to-house service.

There is a double-reduction rear axle of the spiralbevel type, whilst the motor is centrally placed and driven through a Hardy-Spicer needle-roller-jointed propeller shaft. Brakes of the Bendix type operate on all four wheels and are of 10 ins, diameter with 14-in. shoes. Silico-manganese steel is used for the front and rear semi-elliptic springs.

At the price quoted earlier, the vehicle is equipped with Britannia batteries of 128 amp.-hrs. capacity (at the 5-hr. rate). Capacities of 160, 192 and 224 amp.-hrs. are also listed, whilst D.P. and Exide batteries are offered alternatively to the first-named make. The cost with Britannia equipment ranges, according to capacity, from £278 5s. to £317 15s.; with D.P. batteries, from £281 17s. 6d. to £323 2s. 6d.; and with Exide, from £286 to £329 17s. 6d.

A typical consumption figure quoted by the maker frorn actual experience of a machine used in London, under thick traffic conditions, is 165 amp.-hrs. per day,. covering 25 miles, carrying 12 cwt., stopping 135 times and using a 224-amp.-hr. battery. It is also stated that the machine can be operated on a current consumption of 12 to 18 units per day at a cost of 6d. to 9d. according to the local supply company's scale of charges.