Another Method of

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

Increasing the Pay Load

TUERE is, now, quite a number of chassis on the market which has been adapted for the transport of larger loads than is possible in the case of a standard chassis. Most of these modifications have been carried out with Ford or Chevrolet chassis, these having large, powerful engines Which will propel, with ease, heavier loads than had been originally intended. In addition, these vehicles, even when adapted, are well within the means of the small motorvehicle operator.

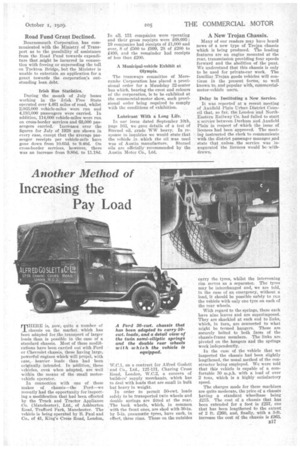

In connection with one of these makes of chassis—the Ford—we recently had the opportunity for inspecting a modification that had been effected by the Truck and Tractor Appliance Co. (Manchester), Ltd., of Ashburton Road, Trafford Park, Manchester. The vehicle is being operated by B. Paul and Co., of 41, King's Cross Road, London, on a contract for Alfred Goslett • and Co., Ltd., 127-131, Charing Cross Road, London, W.C.2, a concern of builders' supply merchants, which has to deal with loads that are small in bulk but heavy in weight.

In order to permit 50-cwt. loads safely to be transported twin wheels and double springs are fitted at the rear. The hack wheels, which, in common -with the front ones, are shod with 30-in. by 5-in, pneumatic tyres, have each, in effect, three rims. Those on the outsides

carry the tyres, whilst the intervening rim serves as a separator. The tyres may be interchanged and, we are told, in the case of an emergency, without a load, it should be possible safely to rum the vehicle with only one tyre on each of the rear wheels.

With regard to the springs, these each have nine leaves and are superimposed. They are shackled at each end to links, which, in turn, are connected to what might be termed hangers. These are securely bolted to both faces of the chassis-frame members. The links are pivoted on the hangers and the springs work independently.

In the case of the vehicle that we inspected the chassis had been slightly lengthened, the usual method of the constructor being employed. We were told that this vehicle is capable of a comfortable 30 m.p.h. with a load of over 2 tons, which is a highly' satisfactory speed.

The charges made for these machines are quite moderate, the price of a chassis having a standard wheelbase being £215. The cost of a chassis that has been extended for a foot is £257, one that has been lengthened to the extent of 2 ft. £260, and, finally, with a 3-ft. increase the cost of the chassis is £263.