PLUGGING INTO THE SMART SET

Page 96

If you've noticed an error in this article please click here to report it so we can fix it.

Legislation and the manufacturers' quest to improve their trucks is fuelling the growth of electronic components used on today's vehicles. Mandatory ABS, elctronic diesel control (EDC) and electronically controlled gear changing (EPS/CAG) and air suspensions (ECAS) — the prospect is daunting. Add to that the problem of recruiting the right calibre of staff plus the shortage of school levers and workshop managers could be forgiven for feeling that they are caught 'twix a rock and a hard place.

There is, however, the prospect of one analyser being able to find faults on all such electronic systems. This happy situation comes about through a rare combination of high technology and common sense. Common sense gives us the DIN standard plug for attaching fault finding equipment. And high technology the capability to easily re-program a single piece of equipment.

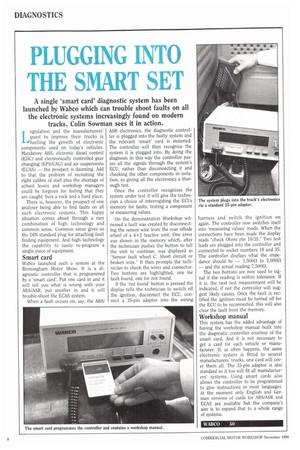

Wabco launched such a system at the Birmingham Motor Show. It is a diagnostic controller that is programmed by a 'smart card'. Put one card in and it will tell you what is wrong with your ABS/ASR, put another in and it will trouble-shoot the ECAS system.

When a fault occurs on, say, the ABS/ ASR electronics, the diagnostic controller is plugged into the faulty system and the relevant 'smart' card is insterted. The controller will then recognise the system it is plugged into. By doing the diagnosis in this way the controller passes all the signals through the system's ECU, rather than disconnecting it and checking the other components in isolation, so giving all the electronics a thorough test.

Once the controller recognises the system under test it will give the technician a choice of interrogating the ECUs memory for faults, testing a component or measuring values.

On the demonstration Workshop witnessed a fault was created by disconnecting the sensor wire from the rear offside wheel of a 4x2 tractive unit. One error was shown in the memory which, after the technician pushes the button to tell the unit to continue, was displayed as "Sensor fault wheel C. Short circuit or broken wire." It then prompts the technician to check the wires and connector. Two buttons are highlighted, one for fault found, one for not found.

If the Snot found' button is pressed the display tells the technician to switch off the ignition, disconnect the ECU, connect a 35-pin adaptor into the wiring harness and switch the ignition on again. The controller now switches itself into 'measuring values' mode. When the connections have been made the display reads "check Ohms pin 18/35." Two test leads are plugged into the controller and connected to socket numbers 18 and 35. The controller displays what the impedance should be — 1,50011 to 2,00011 — and the actual reading 7,50011.

The two buttons are now used to signal if the reading is within tolerance. If it is, the next test measurement will be indicated, if not the controller will suggest likely causes. Once the fault is rectified the ignition must be turned off for the ECU to be reconnected, this will also clear the fault from the memory.

This system has the added advantage of having the workshop manual built into the diagnostic controller courtesy of the smart card. And it is not necessary to get a card for each vehicle or manufacurer. If, as often happens, the same electronic system is fitted to several manufacturers' trucks, one card will cover them all. The 35-pin adaptor is also standard so it too will fit all manufacturers' systems. Using smart cards also allows the controller to be programmed to give instructions in most languages. At the moment only English and German versions of cards for ABS/ASR and ECAS are available but the company's aim is to expand that to a whole range of systems.