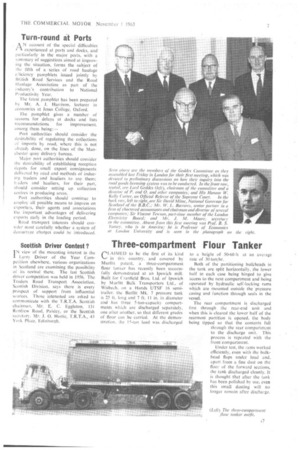

Three-compartment Flour Tanker

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

CLAI kl ED to he the first of its kind in this country. and covered by Murtitt patent, a three-compartment flour tanker has recently been successfully demonstrated at an Ipswich mill. Built for Cranfield Bros. Ltd. of Ipswich by Murtitt Bulk Transporters Ltd., of Wisbech, on a Hands UTSF 16 semitrailer. the Barlitt Mk. 7 pressure tank is 25 ft, long and 7 ft. II in. in diameter and has three 5-ton-capacity compartments which arc discharged separately, one after another, so that different grades of flour can be carried. At the demonstration. the I5-ton load was discharged

to a height. of 504s0 ft at an average rate of 30 ton/lit.

Both of the partitioning bulkheads in the tank are split horizontally, the lower half in each case being hinged to give access to the next compartment and being operated by hydraulic self-locking rams which are mounted outside the pressure casing and function through seals in the vessel.

The rear compartment is discharged first through the rear-end unit and when this is cleared the lower half of the rearmost partition is opened, the body being tipped Sc) that the contents fall through the rear compartment to the discharge unit. This process is repeated with the front compartment.

Under test, the rams worked efficiently, even with the bulkhead flaps under load and, apart from a fine dust on the floor of the forward sections, the tank discharged cleanly. It is thought that after the tank has been polished by use, even this small dusting will no longer remain after discharge.