A Bristol Engine of New Design

Page 95

If you've noticed an error in this article please click here to report it so we can fix it.

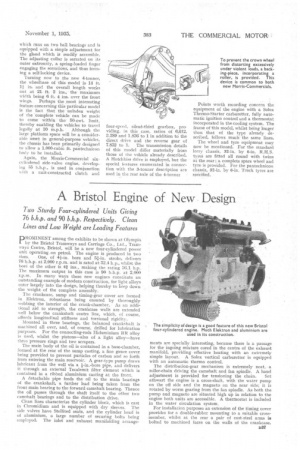

Two Sturdy Four-cylindered Units Giving 76 b.h.p. and 90 b.h.p. Respectively. Clean Lines and Low Weight are Leading Features DROMINENT among the exhibits to be shown at Olympia by the Bristol Tramways and Carriage Co., Ltd., Tramways Centre, Bristol, will be a new four-cylindered power unit operating on petrol. The engine is produced in two sizes. One, of 4-fn. bore and 52-in, stroke, delivers 76 b,h.p. at 2,000 r.p.m. and is rated at 32.4 h.p., whilst the bore of the other is 41 ins., making the rating 36.1 h.p. The maximum output in this case is 90 b.h.p. at 2,000 r.p.m. In many ways these new engines constitute an outstanding example of modern construction, for light alloys enter largely into the design, helping thereby to keep down the weight of the complete assembly.

The crankcase, sump and timing-gear cover are formed in Elektron, robustness being ensured by thoroughly webbing the interior of the crank-chamber, As an additional aid to strength, the crankcase walls are extended well below the crankshaft centre line, which, of course, affords longitudinal stiffness and torsional rigidity.

Mounted in three bearings, the balanced crankshaft is machined all over, and, of course, drilled for lubrication pruposes. For the connecting-rods Ilidurninium RR alloy is used, whilst the pistons—also of a light alloy—have Three pressure rings and two scrapers.

The main body of the oil is contained in a base-chamber, formed at the rear of the sump casting, a fine gauze cover being provided to prevent particles of carbon and so forth tram entering the main reservoir. A gear-type pump draws lubricant from the well via a Fin.-bore pipe, and delivers it through an external Tecalemit filter element which is contained in a ribbed aluminium casting at the front.

A detachable pipe feeds the oil to the main bearings of the crankshaft, a further lead being taken from the front main bearing to the forward camshaft bearing. Thence the oil passes through the shaft itself to the other two camshaft bearings and to the distribution drive.

Clean lines characterize the cylinder block, which is cast in Chromidium and is equipped with dry sleeves. The side valves have Stellited seats, and the cylinder head is of aluminium, a large number of securing bolts being employed. The inlet and exhaust manifolding arrange' ments are specially interesting, because there is a passage for the ingoing mixture cored in the centre of the exhaust manifold, providing effective heating with an extremely simple layout. A Solex vertical carburetter is equipped with an automatic therm° control.

The distribution-gear mechanism is extremely neat, a roller-chain driving the camshaft and fan spindle. A hand

adjustment is provided for tensioning the chain. Set athwart the engine is a cross-shaft, with the water pump on the off side and the magneto on the near side; it is rotated by worm gearing from the fan spindle. As both the pump and magneto are situated high up in relation to the engine both units are accessible. A thermostat is included in the water circulation system.

For installation purposes an extension of the timing cover provides for s double-rubber mounting to a suitable crossmember, whilst at the rear a pair of cast-steel arms is bolted to machined faces on the walls of the crankcase.