WORKSHOP AND GARAGE NOTES.

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Contributions From Our Driver

The Emery Wheel in Garage Work.

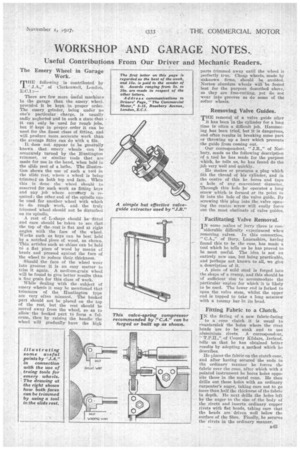

rpHE following is contributed by I. J.A.," of Clerkenwell, There are few more Useful machines in the garage than the emery. wheel, provided it he kept in proper order. The emery grinder, being under no one's particular charge, is usually sadly neglected and in such a state that it can only be used for rough' jobs, but if kept in proper order it can be used for the finest class of fitting, and will. prodace more accurate work than the average fitter can do with a file.

It does not appear to be generally known . that emery wheels can be accurately turned by the Huntington trimmer, or similar tools that are made for use in the hand, when held in the slide reGt of a lathe. The illustration shows the use of such a tool in the 81ide rest, where a wheel is being trimmeJ on both top and face. When this is done the wheel should he reserved fer such work as fitting keys and any job where acculieacy is required; the other end of the spindle can be used for another wheel with which to do rough work, and the truly trimmed wheel should not be disturbed on its spindle.

A rest of L-shape should be, 'fitted and care should be taken to see that the top of the-rest is fiat and at right angles with the face of the wheel. Works such as keys can be best held by a notched piece of wood, as shown. Thin articles such as shims can be held to a flat piece of wood by means ef brads and pressed against the face of the wheel to reduce their thickness.

Should the face of the wheel wear into grooves it is an easy matter to trim it again. A medium-grain wheel will be found to give better results than a fine grain for this class of work.

While dealing with the subject of emery wheels it may be mentioned that trimmers of the Huntington type are very often misused. The booked part should not be placed on the top of the rest, but the rest should be moved away from the wheel, so as to alloW the hooked part to form a fulcrum. then by raising the handle the wheel will gradually have the high parts trimmed away until the wheel is perfectly true. Cheap wheels, made by unknown firms, should be avoided. Norton eland= wheels will be found beat for the purpose described above, as they are free-cutting, yet do not wear into grooves as do some of the softer wheels.

Removing Valve Guides.

THE removal of a valve guide after it has been in the cylinder for a long time is often a difficult job. Hammering has been tried, but it is dangerous, and often results in breaking some part or throwing up a burr which prevents the guide from coming out.

Our correspondent, " J.R.," of Norbury, sends us the following description of a tool he has made for the purpose which, he tells us, he has found do the job very well and quickly.

, He makes or procures a plug which fits the thread of his cylinder, and in the centre of this he bores and taps a hole of any convenient diameter. Through this hole he operates a long screw which, is formed at its point to fit into the hole of the valve guide. By screwing this plug into the valve opening the centre screw will easily force out the most obstinate of valve guides.

Facilitating Valve Removal.

IN some makes of lorry there is considerable difficulty experienced when removing yalves. In this connection, " C.A.," of Bury, Lancashire, having found this to be the case, has made a tool which he tells us he has proved to be most useful. The idea is not an entirely new one, but being practicable, and Perhaps not known to all, we give a description of it.

A piece of mild steel is forged into the shape of 'a cramp, and this should be of sufficient size to accommodate the particular engine for which it is likely to be used. The lower end is forked to span the valve stem, whilst the upper end is tapped to take a long setscrew with a totamy bar in its head.

Fitting Fabric to a Clutch.

IN the fitting of a new fabric-facing

to a cone clutch it is usual to countersink the holes where the rivet heads are to be sunk and to use aluminium rivets. A correspondent, " T.P.H.,".,of County Kildare, Ireland. tells us that he has obtained better results by adopting a method which describes.

He places the fabric on the clittch cone, and after having secured the ends in the ordinary manner he forces the 'fabric over the cone, after which with a pointed instrument be bores holes opposite those in the metal cone. He then drills out these holes with an ordinary carpenter's auger, taking care not to go more than half the thickness of the fabric in depth. He next drills the holes left by the anger to the size of the body of the rivets and inserts, ordinary copper rivets with flat heads, taking care that the heads are driven well below the surface of the fibre. Finally, he secures the rivets in the ordinary manner.