DESIGN

Page 89

Page 90

Page 91

If you've noticed an error in this article please click here to report it so we can fix it.

FLEXIBILITY

boosts export of refrigerated

BY P. A. C. BROCKINGTON A.TV1.1.IVIECH.E. vehicles MOST refrigerated-vehicle manufacturers who cater for overseas markets consider it fortunate with regard to export that the requirements of operators in this country are many and varied. Although in a typical case the manufacturer is faced with the necessity to provide for conditions that are not typical of the United Kingdom, the diverse needs of the home market have created expertise that is applicable, it is claimed, to the requirements of overseas operators virtually throughout the world.

According to the reports of a number of British manufacturers, their preparedness to supply custom-built or modified bodywork to any specification has given them an advantage over their main competitors on the Continent, and progressive expansion of overseas markets can confidently be expected.

This advantage of design and production flexibility would in no way be prejudiced, some makers emphasize, by the adoption of standards for controlled-temperature vehicles currently being formulated under the auspices of the Royal Society of Health, of a similar type to those already existing in America and the Common Market countries. In the opinion of Mr.!. H. Adler, technical director of Smith's Delivery Vehicles Ltd., Team Valley, Gateshead on Tyne, II. such regulations would, by imposing a discipline on the home market, greatly assist the industry in designing vehicles to a standard that would be highly competitive throughout the world.

Apparently, but not necessarily, in conflict with this view, Mr. J. Peachman, development engineer (refrigeration) of Bonallack Mann Egerton Refrigerated Vehicles Ltd., Cromer Road, Norwich. says concentration on standardized bodywork by the two main Continental suppliers of refrigerated vehicles (one of which is a German company and the other, Italian) benefits British manufacturers who can supply more specialized vehicles in greater variety. Mr. Peachman estimates that about 90 per cent of refrigerated vehicles produced for the home market are non-standard and reports that the stock lines introduced from time to time by H.M.E. have had limited application.

The advantages of exporting a refrigerated body and vehicle chassis as a matched combination rather than separate bodies for mounting on chassis locally is emphasized by Mr. A. E. Symonds, a director of J. H. Sparshatt and Sons Ltd., .London Rd., Portsmouth, who advises British makers that this practice offers the best chance of expanding exports to Europe as vvell as more distant markets, despite the success of his company in the supply of bodies to frozen-food manufacturers in Germany and Jamaica, for equipping chassis purchased in the respective countries. Mr. Symonds points•out that the common export problem of maintaining sub-zero operating temperatures at ambient temperatures of 100"F (38.4°C) or over. with up to 50-60 door openings a day, is normally aggravated by the need for a highly robust bodywork construction to cope with indifferent road conditions.

The ability of the refrigerating equipment to withstand the worst possible road conditions that may be encountered is cited by Mr. Symonds as a priority export requirement (Sparshatt trans-desert vehicles operating in Middle East oilfields have highlighted the need for this characteristic) which is secondary only to ease of maintenance and availability of spare parts in all markets. Mr. Symonds •particularly mentions the merits of the packaged type of unit that can be readily installed and removed from the body.

The Sparshatt company standardizes on Thermo King forced-air-convection refrigerating equipment produced by Petters Ltd., of Southampton, for vehicles destined for export because it offers most of the ..advantages outlined by Mr. Symonds and no other company can provide comparable world-wide service facilities. Considerable importance is attached by company executives to the development of markets overseas because the demand for refrigerated vehicles in this country is mainly for replacement rather than additional vehicles.

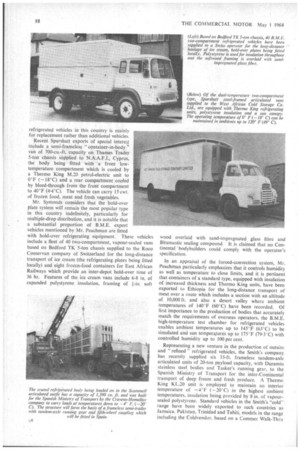

Recent Sparshatt exports of special interet include a semi-frameless "container-in-body * van of 700-cu.-ft. capacity on Thames Trader 5-ton chassis supplied to N.A.A.F.I., Cyprus, the body being fitted with a front lowtemperature compartment which is cooled by a Thermo King M.20 petrol-electric unit to 0°F (-18°C) and a rear compartment cooled by bleed-through from the front compartment to 40°F (4-4°C). The vehicle can carry 15 cwt of frozen food, meat and fresh vegetables.

Mr. Symonds considers that the hold-over plate system will remain the most popular type in this country indefinitely, particularly for multiple-drop distribution, and it is notable that a substantial proportion of B.M.E. export vehicles mentioned by Mr. Peachman are fitted with hold-over refrigerating equipment. These vehicles include a fleet of 40 two-compartment, vapour-sealed vans based on Bedford TK 5-ton chassis supplied to the Roco Conservan company of Switzerland for the long-distance transport of ice cream (the refrigerating plates being fitted locally) and eight frozen-food containers for East African Railways which provide an inter-depot hold-over time of 36 hr. Features of the ice cream vans include 6-8 in. of expanded polystyrene insulation, framing of soft wood overlaid with sand-impregnated glass fibre and Bitumastic sealing compound. It_is claimed that no Continental 'bodybuilders could comply with the operator's specification.

In an appraisal of the forced-convection system, Mr. Peachman particularly emphasizes that it controls humidity as well as temperature to close limits, and it is pertinent that containers of a standard type, equipped with insulation of increased thickness and Thermo King units, have been exported to Ethiopia for the long-distance transport of meat over a route which includes a section with an altitude of 10,000 ft. and also a desert valley where ambient temperatures of 140°F (60°C) have been recorded. Of first importance to the production of bodies that accurately match the requirements of overseas operators, the B.M.E. high-temperature test chamber for refrigerated vehicles enables ambient temperatures up to 145°F (63°C) to be simulated and sun temperatures up to 175°F (79.3°C) with controlled humidity up to 100 per cent.

Representing a new venture in the production of outsize and "refined" refrigerated vehicles. the Smith's company has recently supplied six 33-ft. frameless tandem-axle articulated units of 20-ton payload capacity, with Duramin stainless steel bodies and Tasker's running gear, to the Spanish Ministry of Transport for the inter-Continental transport of deep freeze and fresh produce. A Thermo King KL.20 unit is employed to maintain an interior temperature of —4°F (-20°C) in the highest ambient temperatures, insulation being provided by 8 in of vapoursealed polystyrene. Standard vehicles in the Smith's "cold". range have been widely exported to such countries as Jamaica. Pakistan, Trinidad and Tahiti, models in the range including the Coldvendor, based on a C-ornmer Walk-Thru

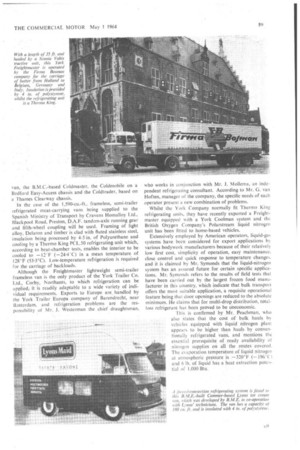

van, the B.M,C.-based Coldmaster: the Coldmobile on a Bedford Easy-Access chassis and the Coldtrader, based on a Thames Clearway chassis.

In the case of the 1,590-cu.-ft., frameless, semi-trailer refrigerated meat-carrying vans being supplied to the Spanish Ministry of Transport by Cravens Homalloy Ltd., Blackpool Road, Preston, D.A.P. tandem-axle running gear and fifth-wheel coupling will be used. Framing of light alloy, Delaron and timber is clad with fluted stainless steel, insulation being processed by 4-5 in. of Polyurethane and cooling by a Thermo King PCL.50 refrigerating unit which, according to heat-chamber tests, enables the interior to be cooled to —12'F (-24-4')C) in a mean temperature of I28'F (53,3°C). Low-temperature refrigeration is required for the carriage of backloads.

Although the Freightmaster lightweight semi-trailer frameless van is the only product of the York Trailer Co. Ltd.. Corby, Northants, to which refrigeration can be applied; it is readily adaptable to a wide variety of indiVidual requirements. Exports to Europe are handled by the York Trailer Europa company of Barendrecht, near Rotterdam, and refrigeration problems are the responsibility of Mr. J. Westerman the chief draughtsman,

who works in conjunction with Mr. J. Mama, an independent refrigerating consultant. According to Mr. G. van Hoften, manager of the company, the specific needs of each operator present a new combination of problems.

Whilst the York Company normally fit Thermo King refrigerating units, they have recently exported a Freightmaster equipped with a York Coolman system and the British Oxygen Company's Polarstrearn liquid nitrogen unit has been fitted to home-based vehicles.

Extensively employed by American operators, liquid-gas systems have been considered for export applications by various bodywork manufacturers because of their relativel■, low first cost, simplicity of operation, easy maintenance, close control and quick response to temperature changes. and it is claimed by Mr. Symonds that the liquid-nitrogen system has an assured future for certain specific applications. Mr. Symonds refers to the results of field tests that have been carried out by the largest frozen food manufacturer in this country, which indicate that bulk transport offers the most suitable application, a requisite operational feature being that door openings are reduced to the absolute minimum. He claims that for multi-drop distribution, totalloss refrigerant has been proved to be uheconomic.

This is confirmed by Mr. .Peachman, who also states that the cost of bulk hauls by vehicles equipped with liquid nitrogen plant appears to be higher than hauls by conventionally refrigerated vans, and mentions the essential prerequisite of ready availability of nitrogen supplies on all the routes covered. The evaporation temperature of liquid nitrogen at atmospheric pressure is .-320°F (-196'(') and 6 lb. of liquid has a heat extraction potential of 1,00C1Btu.