In Search of Oil

Page 111

Page 112

Page 113

If you've noticed an error in this article please click here to report it so we can fix it.

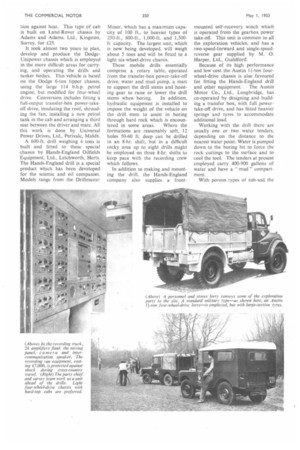

Light and Flexible Allwheel-drive Chassis with High Pcwer-to-weight Ratio are Employed for Oilfield Exploration

WITHIN the past four or five years a new industry has been developed in Britain to supply the oil companies and their subsidiaries with oilfields seismic and servicing equipment and special types of vehicle. Such terms as gin poles, reel trucks, headache racks, and recording, explosives, dynamite, shooting and drill trucks have become commonplace in the British commercial vehicle industry, which not only builds these special chassis but supplies a considerable proportion of the intricate equipment.

The search for new oil-bearing areas is being made in every continent, and the conditions range from treacherous wind-blown sand dunes in the tropical Trucial Oman to marsh land in cooler parts of the world. Vehicles have to he made to compete with heat, dust and humidity, and suspension systems are built to withstand continuous Crosscountry driving.

It is the seismic exploration equipment which has to take the brunt of the bad conditions, because the vehicles may be driven hundreds of miles into the bush, as in Western Australia, or across a corrugated desert to a point which geologists have decided might bear oil.

These seismic parties work as a team, with the party leader and survey ears driving ahead, followed by a mobile drill with attendant water trucks for pumping up the sludge and cooling the drill head. Reel, recording and shooting trucks complete the seismic party. which works in a given area. Holes are drilled for explosive charges, and by laying a series of detectors, termed geophones, on the ground at regular intervals, the earth movement is recorded when the shot is fired.

Although the oil companies have geologist and survey crews in most known oilfields, it is customary to employ a specialist geophysicist group, such as Seismograph Service, Ltd., to explore new areas favourable to the production of oil. Vehicles for such a task have to be built to operate in any part of the world, the preference being for a light all-wheeldrive chassis with abundant power. Originally ex-W.D. types, such as the Bedford QL and Fordson, rebuilt by Scottorn Ltd., New Malden, Surrey, were used while other models were being developed.

The independent seismic company usually contracts to explore an area for an agreed monthly rate, and with keen competition it is essential that operating costs shall be low. Economy has to be observed in purchasing vehicles and equipment, but they have to he thoroughly reliable, because one vehicle off road for repair would stop a whole party from working and cost about 1400 a day.

More recent purchases of vehicles made by the independent companies include the Austin Champ, LandRovers and Austin 11-tonner and Dodge-Unipower fourand six wheelers. A seismic exploration group operating in an area is termed a party, and the vehicles comprise Land-Rovers or Champs for the party chief and surveyors, and heavier chassis for the drills, water tenders, recording, personnel and shooting trucks.

The surveyors work ahead of the group, plotting points at which the drill is to operate. The vehicles for the surveyor and party chief are practically basic in design, apart from a hard-top panelled cab with an insulated head-lining to give protec tion against heat. This type of cab is built on Land-Rover chassis by Adams and Adams, Ltd., Kingston, Surrey, for £25.

It took almost two years to plan, develop and produce the DodgeUnipower chassis which is employed in the more difficult areas for carrying, and operating the drills and tanker bodies. This vehicle is based on the Dodge 6-ton tipper chassis, using the large 114 b.h.p, petrol engine, but modified for four-wheel drive. Conversion includes fitting a full-output transfer-box power-takeoff drive, insulating the roof, shrouding the fan, installing a new petrol tank in the cab and arranging a third seat between the driver and mate. All this work is done by Universal Power Drives, Ltd., Perivale, Middx.

A 600-ft. drill weighing 4 tons is built and fitted to these special chassis by Hands-England Oilfields Equipment, Ltd., Letchworth, Herts. The Hands-England drill is a special product which has been developed for the seismic and oil companies. Models range from the Drillmaster Minor, which has a maximum capacity of 100 ft., to heavier types of 250-ft., 600-ft., 1,000-ft. and 1,500ft. capacity. The largest unit, which is now being developed, will weigh about 5 tons and will be fitted to a light six-wheel-drive chassis.

These mobile drills essentially comprise a rotary table, operated from the transfer-box power-take-off drive, water and mud pump, a mast to support the drill stems and hoisting gear to raise or lower the drill stems when boring. In addition, hydraulic equipment is installed to impose the weight of the vehicle on the drill stem to assist in boring through hard rock which is encoun

tered in some areas. Where the formations are reasonably soft, 12 holes 50-60 ft. deep can be drilled in art 8-hr. shift, but in a difficult rocky area up to eight drills might be employed on three 8-hr. shifts to keep pace with the recording crew which follows.

In addition to making and mounting the drill, the Hands-England company also supplies a front mounted self-recovery winch which is operated from the gearbox power take-off. This unit is common to all the exploration vehicles, and has a two-speed-forward and single-speedreverse gear supplied by M. 0. Harper, Ltd., Guildford.

Because of its high performance and low cost the Austin 1-1-ton fourwheel-drive chassis is also favoured for fitting the Hands-England drill and other equipment. The Austin Motor Co., Ltd., Longbridge, has co-operated by designing and building a transfer box, with full powertake-off drive, and has fitted heavier springs and tyres to accommodate additional load.

Working with the drill there are usually one or two water tenders, depending on the distance to the nearest water point. Water is pumped down to the boring bit to force the rock cuttings to the surface and to cool the tool. The tenders at present employed carry 400-900 gallons of water and have a " mud " compartment.

With porous types of sub-soil the

water would flow to waste, so a proprietary solution, colloquially termed "mud," is pumped down the drill stem as a counter-agent. When a hole has been drilled through sand or other loose soils, it is necessary to case it to prevent the hole from closing in.

The water tenders are usually filled from holes or ponds, using the engine vacuum and special valves designed by Hands-England, to draw the water into the tank. In the Western Australian explorations the nearest water point is 20 miles from the drilling site and the tenders cover 120200 miles a day through the bush.

Recording, reel and shooting trucks follow the drills. The shootingtruck body, built by the Hands

England Oilfields Equipment, Ltd., carries 200-450 gallons of water, a powder box for 300 lb. of dynamite, which is 60 per cent. nitro-glycerine content and 100 detonators.

Charges are made up, lowered into the holes and tamped with water to confine the explosion_ Detectors arc laid out in a regular pattern in the surrounding area, and when the charge is detonated they pick up the earth movement and convert it into electrical energy. This is transmitted to amplifiers in the recording truck to energize a series of galvanometers which trace, with light beams, the earth movements on photographic paper.

The exact instant of detonation, and a timing scale, are also recorded on the sensitized strip, on which it is possible to measure, to the nearest thousandth of a second, the elapsed time intervals from the shot instant

to the recorded reflections. From these time measurements the depths of deeply buried reflecting horizons can be calculated and plotted to form contour maps which indicate the pattern of the sub-surface rocks. If

a favourable hump is indicated, a deep hole may be drilled as the final test for petroleum.

The recording truck is equipped with 25 amplifiers, geophones, automatic volume control and camera, which have to be carefully supported and protected in cross-country driving. A composite-construction body, of which the shell is sub-contracted by Hands-England to Cecil Saunders, Ltd., Letchworth, is employed, but it is stressed with oak supports and the interior is lined with Onazote.

Formerly, the body was mounted direct on the chassis, but it is now supported at the front on four Metacone mountings and, at the rear Metalastik toggle-link units are outrigged from the chassis. It is expected that less damage will now be caused to the equipment, costing 0,000, which is carried in the recording truck. The amplifiers and other electrical equipment are made by Technical and Research Processes, Ltd., London, N.19.

The recording truck works at a safe distance from the shot holes and long cables are required in connect ing the geophones to the amplifiers. These cables are carried on reels, one of which is mounted on the back of the recording and shooting trucks, whilst others are fitted to a LandRover.

Modifications are made to the standard vehicle, so that the reel is mounted on a hub with arrangements for the cable to be run out or hauled in while the vehicle is moving. The reel-truck cab and body are built by Adams and Adams, Ltd.

The two reels, weighing together about 8 cwt. complete with cable, are operated by 12-volt starter motors from a separate bank of batteries. The standard body is reinforced to accommodate the heavy reels and the total weight carried by the LandRover is about 12 cwt.

All the cabs of the seismic vehicles are modified to carry two men in addition to the driver, but a personnel carrier is required for the remainder of the exploration party and stores. The standard militarytype lorry with four-wheel drive ha5 proved an inexpensive and usefu: unit for such duty, because of it ability to operate across country.

Originally, all exploration vehicle! were painted with an aluminiurr preservative compound, but tilt reflection in sunlight was harmful tr the eyes. The colour has beer changed to battleship grey for thi chassis and bodies, whilst the cab: are painted a blending shade.

The special transport equipmen used in bringing the oil to the surfact and conveying it to the port cr refinery will be reviewed later.